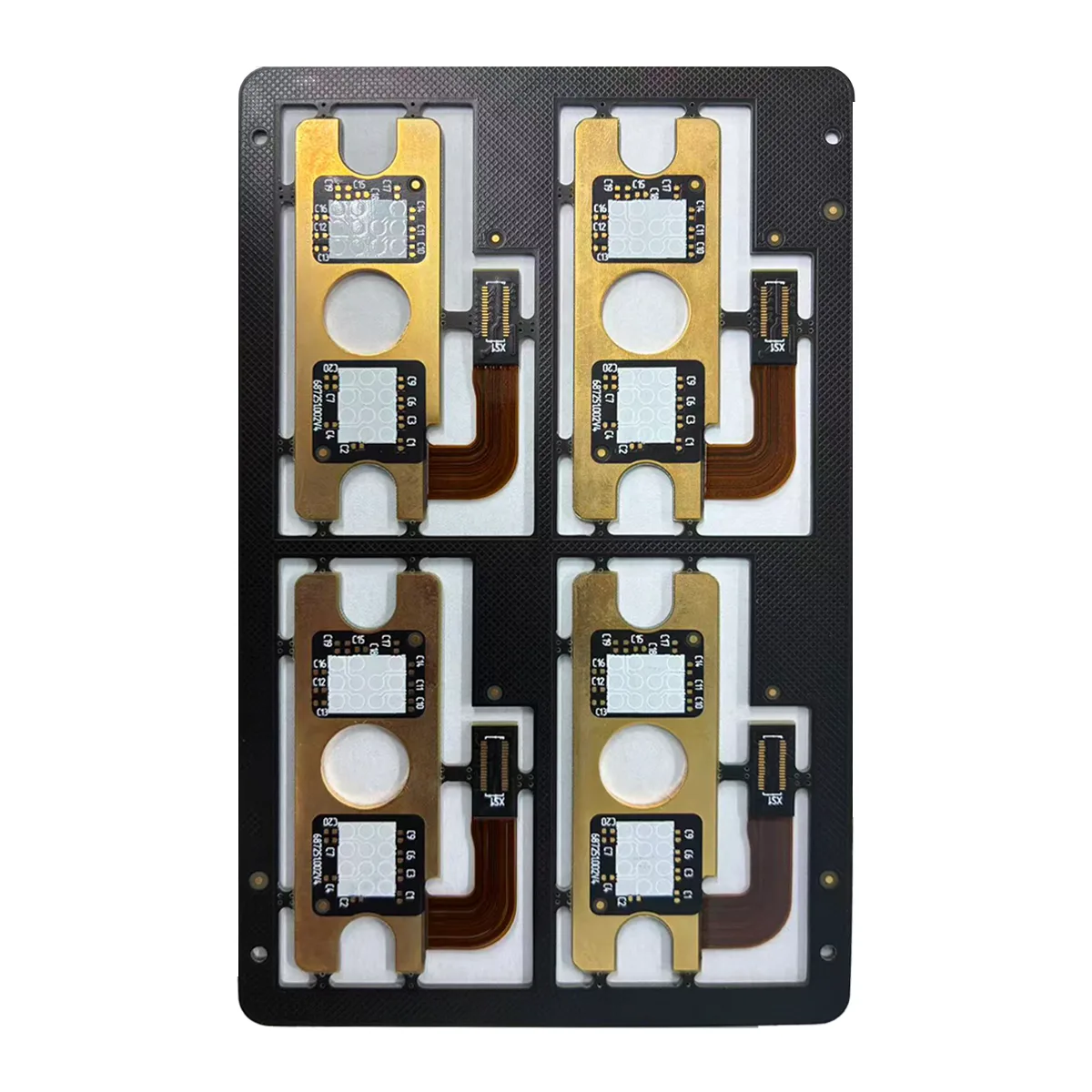

1.UGPCB 4-Layer High Tg Rigid-Flex PCB Product Overview: Redefining High-Reliability Interconnectivity

In modern high-end electronic design, traditional rigid لوحات الدوائر المطبوعة (مركبات ثنائي الفينيل متعدد الكلور) are often limited by space and form factor, while Flexible PCBs (FPCs) may lack mechanical support. ثنائي الفينيل متعدد الكلور جامد فليكس تكنولوجيا, an innovative تصنيع ثنائي الفينيل متعدد الكلور solution, perfectly merges the stability of rigid boards with the bendability of flexible circuits. UGPCB 4-Layer High Tg Rigid-Flex PCB, with its precise lamination structure, superior material selection, and demanding surface finish, stands as the ideal PCB solution for complex 3D spatial layouts and harsh operating environments.

2. Scientific Classification & Core Parameters

-

Scientific Classification: Per معايير IPC and industry norms, this product is accurately classified as a 4-Layer High Thermal Reliability Rigid-Flex Printed Circuit Board.

-

Core Parameters:

-

Layer Construction: 4 طبقات (4L ثنائي الفينيل متعدد الكلور جامد فليكس)

-

Board Thickness: 1.60مم (in rigid areas, including dielectrics and copper)

-

Base Material: Panasonic RF-777 (35/50µm copper)

-

الانتهاء من السطح: يوافق (Electroless Nickel Immersion Gold) 3µ” + Selective Electroplated Hard Gold 30µ”

-

أبعاد: 126مم * 80مم

-

3. Design Essentials & Structure Analysis

Successful Rigid-Flex PCB design is critical. This product is designed adhering to these key points:

-

Rigid-to-Flex Transition Zone Design: Bend areas are meticulously simulated, avoiding right and acute angles. Smooth curved traces are implemented to eliminate stress concentration points, a cornerstone of high-reliability PCB design.

-

Stack-up Symmetry: Rigid sections employ a symmetrical lamination stack-up (على سبيل المثال, copper-dielectric-core-dielectric-copper) to prevent warping under thermal stress.

-

Material Compatibility: The selected Panasonic RF-777 material has matched Coefficients of Thermal Expansion (CTE) in both rigid and flexible zones, ensuring robust bonding at the interfaces.

Structural Feature: The board is constructed by laminating two rigid outer sections with a multilayer structure containing flexible inner layers, enabling electrical interconnection in three-dimensional space.

Image Suggestion 2: A detailed cross-sectional diagram of the board’s layer stack-up, clearly labeling rigid areas, flex areas, مواد, and thicknesses.

Alt Tag: Cross-section diagram of a 4-Layer Rigid-Flex PCB stack-up, showing the integration of rigid FR-4 and flexible polyimide materials.

4. مواد & Performance

-

Core Material: Panasonic RF-777. This is a high-performance laminate specifically optimized for Rigid-Flex PCB fabrication.

-

High Glass Transition Temperature (تيراغرام): Provides excellent thermal stability, maintaining mechanical and electrical properties during high-temperature soldering (على سبيل المثال, lead-free reflow) and in high-temperature operating environments.

-

Low Dk (ثابت العزل الكهربائي) & ص (عامل التبديد): Ensures signal integrity for عالي التردد ثنائي الفينيل متعدد الكلور التطبيقات.

-

Superior Dimensional Stability & Chemical Resistance: Guarantees long-term reliability.

-

-

الانتهاء من السطح: ENIG 3µ” + Electroplated Hard Gold 30µ”. This combination is a key differentiator.

-

يوافق: Provides a flat, highly solderable surface finish across the entire board, suitable for fine-pitch component assembly.

-

Electroplated Hard Gold: Applied selectively to connector fingers or areas subject to frequent insertion/withdrawal or friction, the 30µ” hard gold layer dramatically increases wear resistance, oxidation resistance, and contact reliability, extending connector lifecycle.

-

5. Manufacturing Process Flow

UGPCB employs industry-leading PCB production processes to ensure quality:

-

Laser & Mechanical Drilling: High-precision drilling for varying hole size requirements.

-

Hole Metallization & تصفيح: Ensures interlayer connectivity.

-

Patterning & النقش: Forms precise circuit patterns.

-

التصفيح & Pressing: Precisely bonds rigid and flexible layers into a single unit under high heat and pressure—the technical core of rigid-flex circuit board processing.

-

التشطيب السطح: Sequential application of ENIG and selective hard gold plating.

-

Contour Routing & الاختبار: Final outline achieved via CNC and laser routing, followed by الهيئة العربية للتصنيع (الفحص البصري الآلي), electrical testing, and flex-cycle reliability testing.

Image Suggestion 3: An image of a modern PCB production line, focusing on a lamination press or AOI inspection station.

Alt Tag: UGPCB’s modern Rigid-Flex PCB production line featuring high-precision lamination and inspection equipment for quality assurance.

6. المزايا الرئيسية & Product Features

-

3D Design Freedom: Solves complex spatial layout challenges, reduces connectors and cabling, and enhances system reliability.

-

Exceptional Mechanical & الأداء الكهربائي: High-strength flex joints withstand thousands of dynamic bend cycles; shortened signal paths reduce loss.

-

High Reliability Assurance: High Tg material and dual surface finish ensure stable long-term operation in harsh environments (high temperature, humidity, vibration).

-

Weight & Size Reduction: Contributes to overall device miniaturization and lightweight design.

7. Typical Applications

هذا 4-Layer Rigid-Flex PCB is the preferred PCB component for demanding sectors:

-

صناعي & إلكترونيات السيارات: Vibration-resistant connections in control systems, automotive sensors, and Engine Control Units (ECUs).

-

الأجهزة الطبية: Endoscopes, portable monitors, hearing aids—devices requiring precise, موثوق, and bendable interconnects.

-

الفضاء & الدفاع: Avionics and military electronics where weight, space, and reliability are paramount.

-

High-End Consumer Electronics: Camera module connections in smartphones, hinge connections in wearables, advanced digital cameras.

8. لماذا تختار UGPCB?

As a professional الشركة المصنعة لثنائي الفينيل متعدد الكلور, UGPCB specializes in ثنائي الفينيل متعدد الكلور جامد فليكس تكنولوجيا, offering full-spectrum capabilities from PCB design support and precision تصنيع ثنائي الفينيل متعدد الكلور to rigorous PCB testing. We commit to:

-

Expert Engineering Support: Free PCB design for manufacturing consultation for your project.

-

Consistent, Reliable Quality: Every board undergoes stringent reliability testing.

-

Competitive Pricing & Lead Times: Optimized supply chain and production management deliver high-value PCB solutions.

Contact UGPCB today for a free prototype evaluation and quote. Let our professional تصنيع ثنائي الفينيل متعدد الكلور services power your innovative product to market success.