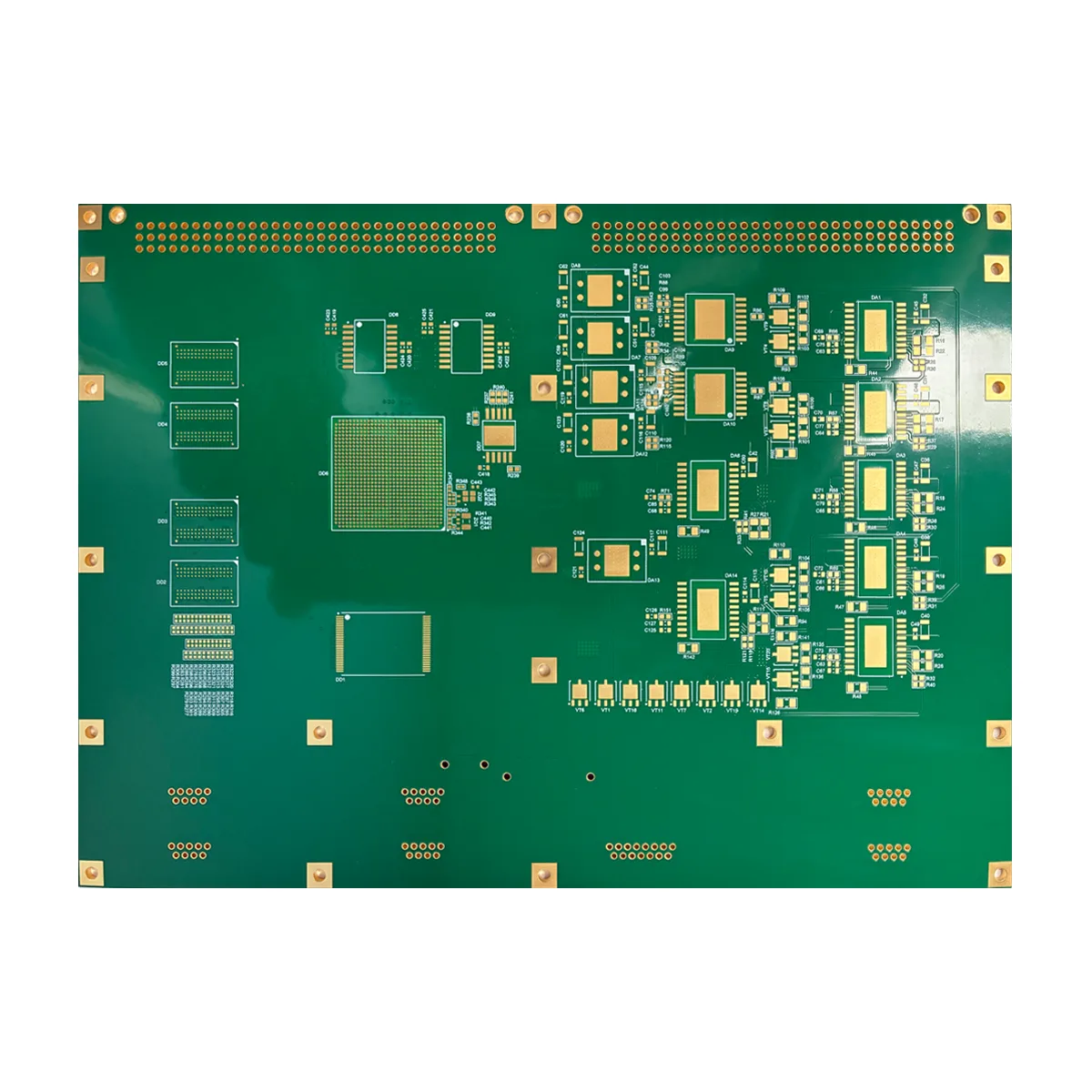

In the era of high-speed data transfer and precision computing, the performance of the لوحة الدوائر المطبوعة (ثنائي الفينيل متعدد الكلور)—the core brain of electronic devices—determines the entire system’s capability. UGPCB introduces its high-performance 18-layer rigid PCB based on Megtron-7 material, engineered to meet the most demanding electrical and physical challenges, serving as the essential foundation for your next-generation advanced equipment.

1.18-Layer Megtron-7 Rigid PCB Product Overview & Definition

This product is an 18-layer rigid high-layer count PCB with a precisely controlled thickness of 1.86مم and overall dimensions of 165mm x 120mm. It utilizes industry-leading Megtron-7 high-speed low-loss laminate and features a 2-microinch (approx. 0.05µm) Electroless Nickel Immersion Gold (يوافق) surface finish. This specification represents an advanced tier in عالية الأداء تصنيع ثنائي الفينيل متعدد الكلور, designed for applications where signal integrity, الإدارة الحرارية, and reliability are paramount.

2. اعتبارات التصميم الحرجة

Designing a successful 18-layer PCB, especially with high-speed materials like Megtron-7, requires careful attention to several core aspects:

-

Stack-up Design: A rational layer stack-up is critical for impedance control and crosstalk reduction. A typical 18-layer stack includes multiple signal, قوة, and ground planes to ensure stable power distribution and clear signal return paths.

-

السيطرة على المعاوقة: High-speed signal transmission demands precise controlled impedance PCB design. Trace width and spacing must be calculated accurately based on the Dk (ثابت العزل الكهربائي) and Df (عامل التبديد) of Megtron-7. We offer professional impedance calculation and simulation services.

-

الإدارة الحرارية: The 1.86mm board thickness and multi-layer structure necessitate effective thermal pathways in the design, such as using thermal vias to connect internal copper layers for efficient heat dissipation from components.

-

ربط عالية الكثافة (مؤشر التنمية البشرية) Considerations: While this is a standard through-hole design, careful planning of via types (blind, buried, through-hole) is essential at this layer count to minimize stub effects and optimize signal paths.

3. How It Works & Structure

أ multi-layer PCB functions like a highly integrated, three-dimensional “road network.” Electrical signals travel on copper traces (“roads”) on the surface and internal layers, with vertical connections between layers established through plated through-holes (“interchanges”). Dedicated power and ground planes provide stable voltage reference and noise shielding for the entire system. هذا 18-layer rigid PCB is formed through a precise lamination process, bonding multiple core layers and prepreg sheets into a single, robust unit with excellent electrical properties. Its sophisticated PCB board structure is the foundation for implementing complex circuit functionalities.

4. Core Materials & Key Performance

-

Materials Used:

-

صفح: Megtron-7. This is a high-performance, low-loss copper-clad laminate from Panasonic, renowned for its stable dielectric constant (Dk ~3.3) and extremely low dissipation factor (Df ~0.001). It is optimized for applications above 10GHz and into millimeter-wave frequencies.

-

احباط النحاس: Utilizes Very Low Profile (VLP) or Reverse Treated Foil (RTF) to minimize “skin effect” losses caused by signal transmission on rough copper surfaces.

-

الانتهاء من السطح: Electroless Nickel Immersion Gold (يوافق, 2u”). Provides a flat surface, excellent solderability, a reliable contact interface (suitable for gold fingers), and long shelf life.

-

-

Outstanding Performance:

-

Superior Signal Integrity (و): Exceptionally low signal loss ensures high-speed pulse waveforms remain undistorted.

-

Excellent Power Integrity (PI): Multiple dedicated power and ground planes offer very low power distribution network impedance and superior decoupling.

-

High Reliability: The 1.86mm board thickness and premium materials deliver high mechanical strength, heat resistance, and long-term environmental stability.

-

Stable Impedance Control: Achieved through material consistency and precision manufacturing processes.

-

5. Product Classification

According to industry and IPC standards, this product is accurately classified as:

-

By Layer Count: High-Layer Count PCB (typically defined as 10+ طبقات).

-

By Material Type: High-Speed High-Frequency PCB / Low-Loss PCB.

-

By Structure: Rigid PCB.

-

By Technology: Controlled Impedance PCB, ENIG Finished PCB.

-

By Application Grade: Industrial Grade / Telecommunications Grade High-Performance PCB.

6. الميزات الرئيسية & Benefits

-

Premium Material: Built on Megtron-7 high-speed laminate, providing the physical basis for superior electrical performance.

-

High Complexity Capacity: ال 18-layer circuit board design allows for extremely complex and dense circuit layouts.

-

Precision Manufacturing: Strict tolerance control on the 1.86mm board thickness and consistent 2u” ENIG surface finish application.

-

Engineered for Speed: Optimized throughout—from design and material selection to processing—for high-speed digital circuits و RF/microwave circuits.

7. Production Process Overview

ال high-layer count PCB manufacturing process is highly precise: Material Cutting → Inner Layer Imaging & Etching → Automated Optical Inspection (الهيئة العربية للتصنيع) → Lamination (Pressing multiple inner layer cores with prepreg) → Drilling → Hole Metallization (Desmear, Electroless & Electrolytic Copper Plating) → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → Surface Finish (يوافق) → Profile Routing → Electrical Testing → Final Inspection. Each step requires stringent control, particularly layer-to-layer registration and impedance control.

8. التطبيقات الأولية & Use Cases

هذا high-performance PCB board is the ideal choice for the following advanced applications:

-

High-Speed Communication Equipment: Core motherboards for 400G/800G optical modules, high-end routers, and switches.

-

Advanced Computing & تخزين: Server motherboards, AI accelerator cards, high-speed storage array (SSD) controller boards.

-

Precision Test & Measurement Instruments: Internal core boards for high-end oscilloscopes, spectrum analyzers, and signal generators.

-

الفضاء & Defense Electronics: Processing units within radar systems and satellite communication payloads.

-

Advanced Medical Imaging Devices: High-speed data acquisition and processing boards for equipment like MRI and CT scanners.

Why Choose UGPCB for Your 18-Layer Megtron-7 PCBs?

We deliver more than just a لوحة الدائرة; we provide a complete solution encompassing سوق دبي المالي (تصميم للتصنيع) review, precision manufacturing, و اختبار الموثوقية. We possess deep expertise in every detail of high-layer count تصنيع ثنائي الفينيل متعدد الكلور, ensuring your design is translated into reality with the highest quality and reliability.

Contact us today for a free technical assessment and a competitive quote for your project. Let UGPCB be the robust foundation for your high-end product’s success.