UGPCB: Pioneering High-Density Interconnect Innovation with Advanced HDI PCB Technology

Industry-Leading HDI PCB Manufacturing Capabilities

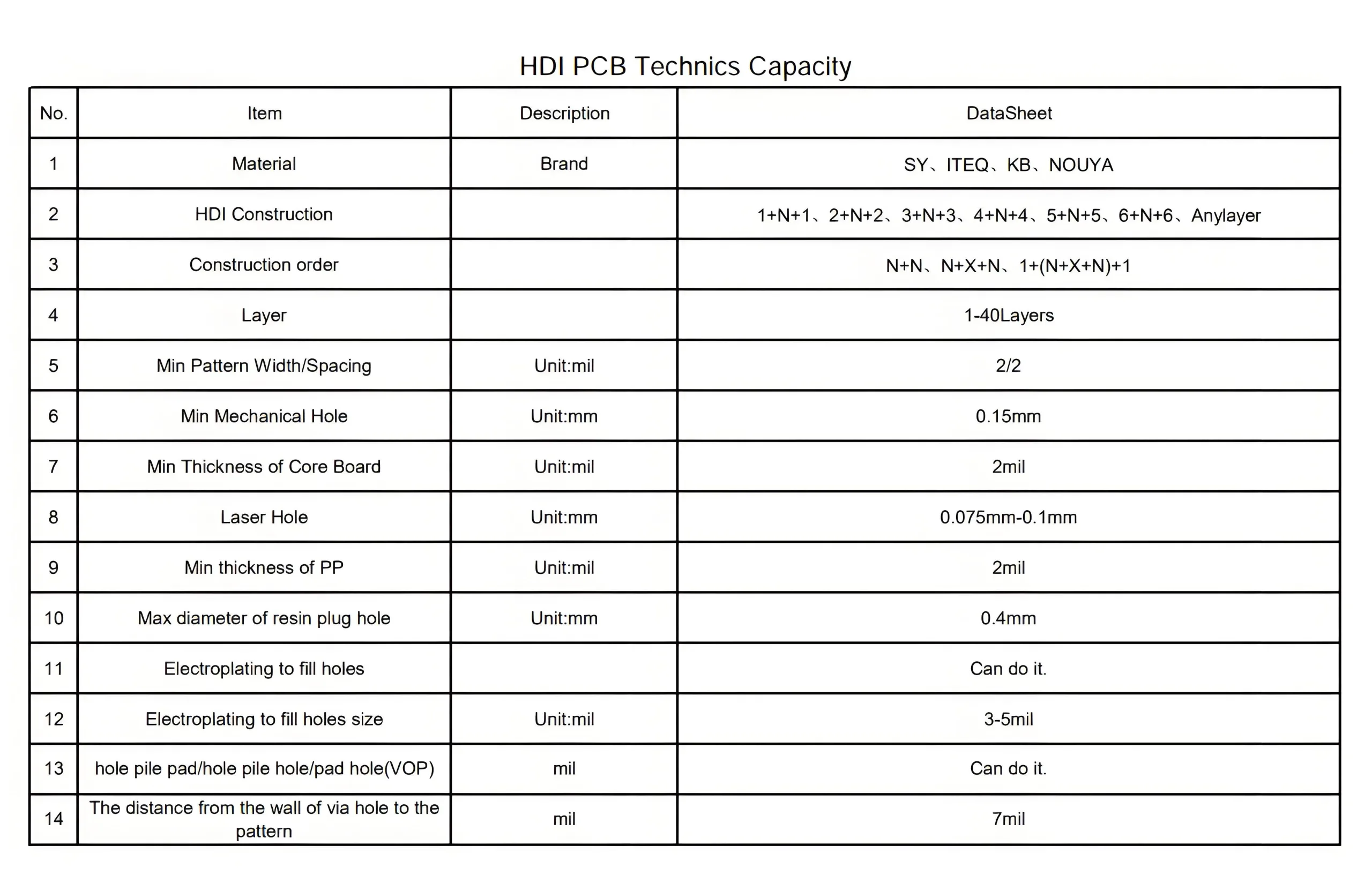

UGPCB stands at the forefront of HDI (High-Density Interconnect) PCB technology, driving progress in an era where electronic devices demand unprecedented thinness and functionality. Specializing in 4-40 layer multilayer boards with thickness ranging from 0.4mm to 6.0mm, we cater to diverse needs from consumer electronics to premium communication equipment.

Our cutting-edge Any-layer HDI technology enables seamless interconnection across over 10 PCB layers, delivering robust connectivity solutions for high-performance computing and communication devices. This capability positions us as a trusted partner for next-generation electronic applications.

Process Technology: Precision Meets Reliability

Advanced Equipment & Innovation

UGPCB sets industry benchmarks in HDI PCB manufacturing through state-of-the-art equipment and process innovation:

- Laser Drilling: Achieves microvia processing as small as 0.075mm (3mil) with precision exceeding industry standards

- Microvia Technology: Hidden interconnections through next-layer vias eliminate fan-in/fan-out routing, significantly enhancing circuit density

- Impedance Control: Maintains +/-7% impedance tolerance for superior signal integrity in 5G and high-performance computing applications

Comprehensive Manufacturing Process

Our HDI production workflow integrates:

- Laser Drilling: CO₂ laser systems ensure consistent hole quality and cleanliness

- Plating Process: 12-18μm copper thickness guarantees electrical reliability

- Pattern Transfer: Supports 1.5/1.5mil minimum line width/spacing for ultra-dense routing

- Lamination Technology: Layer alignment accuracy within ±200μm ensures structural stability

We utilize high-performance PCB substrates including high-Tg FR-4 (140/150/170℃) and polyimide materials to ensure stable performance in high-temperature environments.

Quality Assurance & Testing Systems

Multi-Layered Inspection Protocols

UGPCB implements rigorous quality control through:

- AOI (Automatic Optical Inspection)

- Flying Probe Testing

- X-ray Inspection

Microvia Reliability

The inherent reliability of our microvia technology stems from:

- Thinner construction with 1:1 aspect ratio

- Superior signal transmission stability compared to traditional through-holes

- Enhanced long-term durability for demanding applications

Applications: Empowering Cutting-Edge Technologies

UGPCB’s HDI PCBs power high-tech applications across multiple sectors:

- 5G Communication: High-frequency PCBs for 5G base stations and RF modules

- Automotive Electronics: Stable signal transmission for navigation and entertainment systems

- Medical Devices: Precision data acquisition for patient monitors and surgical instruments

- Industrial Control: Efficient data exchange for PLCs and sensor networks

Technical Advantages: Why Choose UGPCB?

Superior Performance Features

- Space Efficiency: Microvia/blind via designs reduce PCB footprint by up to 30%

- Signal Integrity: Low-DK materials minimize signal delay and crosstalk for high-speed transmission

- Design Flexibility: Enables complex circuits in compact spaces

- Thermal Management: Dedicated thermal layers improve heat dissipation for high-power applications

R&D Direction & Future Outlook

Next-Gen Technology Investment

UGPCB actively develops HDI PCBs with:

- Higher density and finer lines

- Lower signal loss characteristics

- Laser drilling advancements

- Nanomaterial integration

- Smart manufacturing systems

Our R&D team focuses on advanced microvia technologies and material innovations to support client roadmaps for 5G, AI, and IoT devices.

Conclusion: Your Trusted HDI PCB Partner

Industry Leadership

As an HDI PCB technology leader, UGPCB delivers:

- Advanced process capabilities

- Stringent quality control

- Continuous technological innovation

Comprehensive Solutions

From smartphones to automotive systems, we provide total high-density interconnect solutions. Choosing UGPCB means selecting:

- Superior performance

- Reliable quality

- Technological foresight

Contact UGPCB today to explore how our HDI PCB technology can empower your next-generation products.