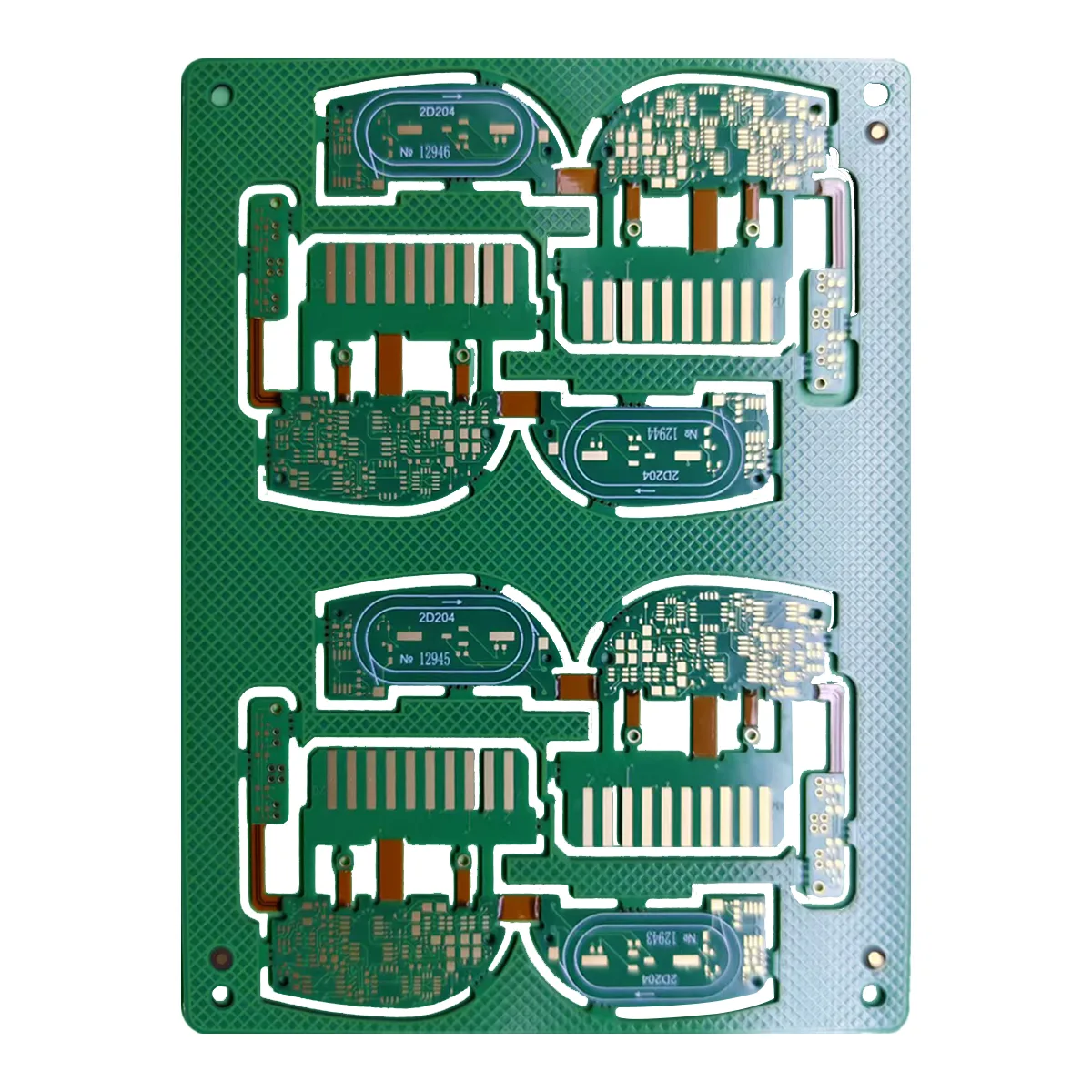

UGPCB’s 0.22mm Ultra-Thin 6-Layer HDI Rigid-Flex PCB Produktübersicht

In the pursuit of extreme device miniaturization and high reliability, traditional rigid Leiterplatten (Leiterplatten) are often insufficient. UGPCB combines advanced Hochdichte Interconnect (HDI) Und Rigid-Flex technologies to present our flagship product: Die 0.22mm Ultra-Thin 6-Layer HDI Rigid-Flex PCB. This board is a pinnacle of Leiterplattenherstellung und a high-performance interconnect solution engineered for wearable technology, advanced medical instruments, Luft- und Raumfahrt, and premium consumer electronics. It seamlessly merges the stable support of rigid boards with the dynamic bending capability of flexible circuits, enabling complex electrical connections within minimal space.

Product Definition & Wissenschaftliche Klassifikation

Dies ist a high-layer-count PCB utilizing HDI mit beliebiger Schicht Und rigid-flex construction. It can be accurately classified per industry standards:

-

Durch Struktur: Starr-Flex-Leiterplatte – Laminates rigid and flexible circuit layers into a single unit.

-

By Technology Level: Advanced HDI PCB – Employs laser drilling, filled vias, and microvias (<0.15mm) for superior routing density.

-

Für Schichtzahl: 6-Layer Circuit Board (comprising both rigid and flexible layers).

-

Durch Material: Specialty High-Performance Material PCB – Core build-up uses Panasonic RF-777 composite.

Design-Grundlagen & Arbeitsprinzip

Design-Grundlagen: The key to a successful rigid-flex board design lies in the rigid-to-flex transition zone. Precise calculation of bend radius, stress relief, and routing in flex areas is critical to prevent cracking during dynamic flexing. Gleichzeitig, HDI blind and buried via design must coordinate with the stack-up structure to optimize signal integrity (UND) and power integrity (PI).

Arbeitsprinzip: Der PCB-Struktur integrates rigid sections (for component mounting and mechanical support) with flexible sections (for 3D interconnection and movement) über mehrschichtige Laminierung. Electrical signals travel through laser-drilled microvias Und via filling plating technologies inherent to HDI -Boards, achieving the shortest and most reliable paths between layers, which minimizes signal loss and crosstalk.

Kernmaterialien & Superior Performance

-

Kernmaterial: We utilize the industry-premium Panasonic RF-777 35/50 Verbundwerkstoff. Renowned for its exceptional Dimensionsstabilität, superior high-frequency performance, and excellent Wärmewiderstand, it is the ideal choice for manufacturing high-reliability rigid-flex circuit boards.

-

Oberflächenbeschaffung: The board features a 2-micron Electroless Nickel Immersion Gold (ZUSTIMMEN) beenden. This provides a flat surface, ausgezeichnete Lötbarkeit, and long-term oxidation resistance for PCB pads, making it perfect for mounting fine-pitch components like BGAs.

-

Key Performance Attributes:

-

Ultra-Thin 0.22mm Profile: Enables maximum compression of internal device space.

-

Hohe Zuverlässigkeit: Undergoes rigorous PCB reliability testing, capable of withstanding millions of dynamic bend cycles.

-

Excellent Signal Transmission: HDI-Design and premium materials ensure low-loss transmission for high-speed signals.

-

High-Density Assembly: Provides an ideal platform for SMT -Baugruppe, supporting miniaturized component layout.

-

Struktur & Schlüsselmerkmale

-

PCB Structure: A typical 6-layer construction involving 2-4 layers of rigid FR-4 laminated with polyimide flexible cores. Der stack-up is meticulously engineered to balance stiffness and flexibility.

-

Produktmerkmale:

-

3D Interconnection Freedom: Eliminates spatial constraints, enabling 3D assembly and reducing connectors and cables.

-

Leicht & Miniaturization: The extreme thinness directly reduces product weight and size.

-

Enhanced System Reliability: Removes connection point failures, improving overall stability in vibrating or high-shock environments.

-

Simplified Assembly Process: As a custom Leiterplattenbestückung, it streamlines final product assembly, lowering labor costs.

-

Precision Manufacturing Process

UGPCB adheres to international quality standards like IPC-6013 (for flexible circuits) Und IPC-2221/2223. Unser PCB fabrication process is precise and rigorous:

-

Laserbohren: Creates micron-level blind and buried vias in flexible and core layers.

-

Hole Metallization & Überzug: Vias are made conductive through chemical deposition and plating, mit via filling for planarization.

-

Musterübertragung & Radierung: Forms the intricate circuit board traces.

-

Schichtausrichtung & Laminierung: Rigid layers, Prepreg, and flexible layers are precisely aligned and bonded under high heat and pressure. This is the core step in rigid-flex PCB manufacturing.

-

Oberflächenbearbeitung: Application of the ZUSTIMMEN coating to protect pads and ensure solderability.

-

Strenge Tests: Includes Flying-Probe-Tests, Automatisierte optische Inspektion (AOI), and reliability testing to ensure every board’s quality.

Wide-Ranging Application Scenarios

Das advanced PCB is the core skeleton for innovative products in:

-

Tragbare Technologie: Smartwatches, AR/VR glasses, health monitors, requiring comfort and constant flexing.

-

Advanced Medical Electronics: Endoscopic capsules, hearing aids, portable monitors, demanding high reliability and miniaturization.

-

Luft- und Raumfahrt & Verteidigung: Satellite components, UAV flight control systems, needing extreme environment endurance and low weight.

-

Precision Consumer Electronics: High-end smartphone camera modules, folding phone hinge areas, ultra-thin laptops.

-

Industriell & Kfz -Elektronik: Compact sensors, robotic joint interconnection modules.

Contact a UGPCB PCB Technical Expert today for your 0.22mm Ultra-Thin HDI Rigid-Flex PCB solution! Make your product stand out in the competition for miniaturization and high performance.