Engineer Superior RF Performance: The UGPCB RO4350B Ceramic Hybrid High Frequency PCB Solution

In the era of 5G, Radar, und Satellitenkommunikation, the performance of your Hochfrequenz -PCB is critical to system success. Selecting a PCB laminate that offers exceptional RF characteristics, Zuverlässigkeit, and cost-effectiveness is paramount for every RF engineer and procurement specialist. UGPCB, ein führender Leiterplattenhersteller Und PCBA service provider, presents its advanced Ceramic Hybrid High Frequency PCB utilizing Rogers RO4350B and FR4 lamination technology. We deliver a complete solution from PCB-Design Zu Leiterplattenbestückung (Leiterplatte).

1. Produktübersicht & Definition

Der RO4350B Keramik-Hybrid-Hochfrequenz-Leiterplatte is a high-performance Leiterplatte engineered for radio frequency (Rf) and microwave applications. It innovatively combines Rogers RO4350B ceramic-filled hydrocarbon laminate with standard FR4 epoxy glass material through Multi-Layer-PCB lamination technology. This “hybrid” approach allows critical RF circuits (z.B., Antennen, Filter, amplifiers) to be routed on the low-loss RO4350B areas, while cost-sensitive digital control and power management circuits reside on the FR4 areas, achieving an optimal balance between performance and cost.

2. Kernmaterial & Konstruktion

-

Materialien: This product features a Rogers RO4350B + FR4 mixed laminate Konstruktion. RO4350B is a ceramic-filled thermoset polymer material known for its stable dielectric constant (Dk) und niedriger Dissipationsfaktor (Df). FR4 is a standard epoxy glass weave laminate, valued for its economy and versatility.

-

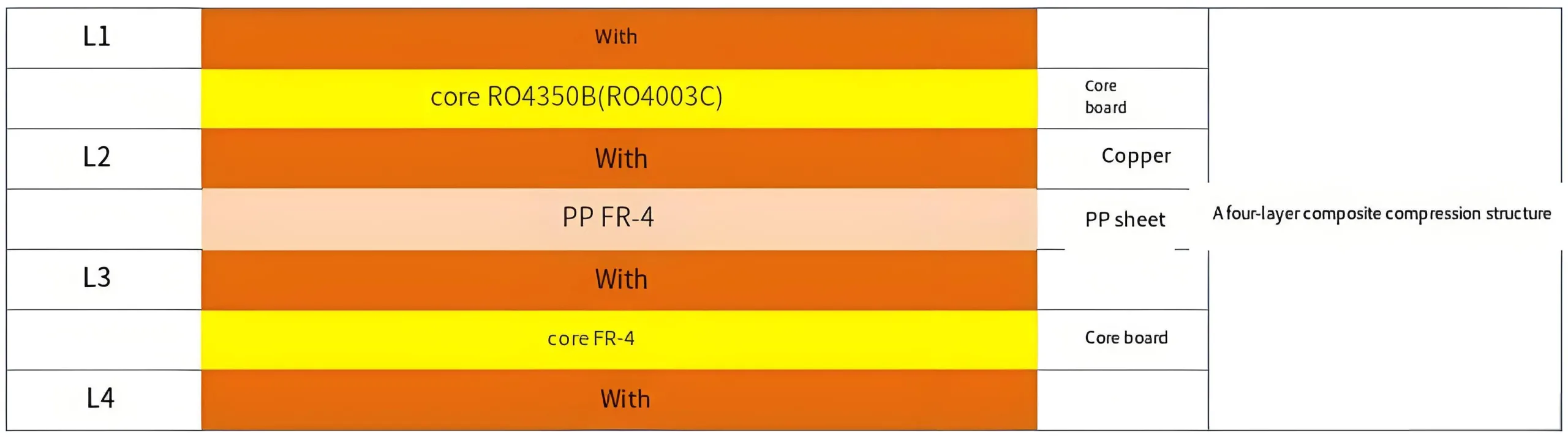

Konstruktion: This model is a standard 4-Schichtplatine. Typischerweise, the outer layers (L1 & L4), which host RF circuitry, use RO4350B dielectric, bonded to the inner FR4 core using prepreg. This structure ensures signal integrity in RF paths while reducing overall material cost.

-

Schlüsselspezifikationen & Einhaltung:

-

Dielektrizitätskonstante (Dk): 3.48 @ 10 GHz. This stable value minimizes phase shift and impedance variance, entscheidend für controlled impedance PCB design.

-

Wärmeleitfähigkeit: 0.69 W/m · k. Superior to standard FR4, aiding heat dissipation from active RF components and improving long-term reliability.

-

Entflammbarkeitsbewertung: UL 94 V-0. Meets the highest standard for flame retardancy.

-

Oberflächenbeschaffung: Immersionsgold (ZUSTIMMEN). Provides a flat, solderable surface, excellent oxidation resistance, and long shelf life, Ideal für high-frequency SMT assembly Und PCBA processes.

-

Fertige Dicke: 1.0 mm

-

Kupfergewicht: 1 oz (35 μm)

-

3. Überlegungen zum kritischen Design & Funktionsprinzip

-

Impedanzkontrolle: RF transmission lines (z.B., microstrip, stripline) require precise impedance control (typically 50Ω or 75Ω). Designers must calculate trace width using the stable Dk of RO4350B (3.48) and dielectric thickness (0.762mm) to ensure minimal signal reflection.

-

Hybrid Zone Transition: Signal transitions between RO4350B and FR4 areas cause impedance discontinuities due to Dk mismatch. Optimal PCB-Layout requires mitigation techniques like tapered traces, matching networks, or optimized via transitions.

-

Thermalmanagement: Despite its improved thermal conductivity (0.69 W/m · k), high-power RF designs may still require thermal vias, heatsinks, or metal-core substrates for effective PCB thermal management.

-

Funktionsprinzip: Das Leiterplatte acts as the physical substrate and transmission medium for RF signals. Its core function is to utilize the low-loss, low-dispersion properties of RO4350B to transmit electromagnetic signals with high efficiency and minimal distortion across target frequency bands (from hundreds of MHz to tens of GHz), while integrating control logic via the hybrid structure for complete system functionality.

4. Schlüsselmerkmale & Vorteile

-

Exceptional High-Frequency Performance: Low loss and stable Dk/Df ensure superior Signalintegrität.

-

Optimized System Cost: Hybrid construction significantly reduces the use of premium material, offering a cost-effective PCB solution.

-

Hohe Zuverlässigkeit & Haltbarkeit: V-0 flammability rating and robust thermal performance ensure stability in demanding environments.

-

Design & Assembly Friendly: Compatible with standard Leiterplattenfertigung Und SMT assembly processes, streamlining PCBA-Produktion.

5. Herstellungsprozess

UGPCB adheres to a strict Qualitätskontrolle regime for high frequency PCB manufacturing:

Material Prep & Inner Layer Imaging → Hybrid Lamination & Registration → Precision Drilling & Plating → Pattern Imaging & Etching → Impedance Control Testing → Solder Mask & Oberflächenbeschaffung (ZUSTIMMEN) → Electrical Testing & Final Audit → Shipping. Each step is specially controlled for high-frequency characteristics.

6. Primäranwendungen & Anwendungsfälle

This product is ideal for applications demanding high frequency and signal fidelity:

-

Wireless Communications: 5G base station antennas/RF modules, microwave backhaul, satellite communication terminals.

-

Kfz -Elektronik: Millimeter-wave radar (77 GHz), V2X telematics modules.

-

Luft- und Raumfahrt & Verteidigung: Radar systems, electronic warfare (EW) Ausrüstung, guidance systems.

-

Test & Measurement: Kern RF circuit boards in network analyzers, spectrum analyzers, and high-frequency signal sources.

Partner with UGPCB for Your High-Frequency Projects

Whether you are an engineer engaged in RF PCB layout or a sourcing professional seeking a reliable circuit board supplier, UGPCB’s RO4350B Hybrid High Frequency PCB is your ideal solution. We provide not only high-quality Leiterplattenfertigung but also full-spectrum support from Überprüfung des PCB-Designs to end-to-end PCBA services, accelerating your time-to-market.

Kontaktieren Sie uns today for a free design consultation and a competitive quote. Power your next RF innovation with UGPCB.