In the era of high-speed data transfer and precision computing, the performance of the Leiterplatte (Leiterplatte)—the core brain of electronic devices—determines the entire system’s capability. UGPCB introduces its high-performance 18-layer rigid PCB based on Megtron-7 Material, engineered to meet the most demanding electrical and physical challenges, serving as the essential foundation for your next-generation advanced equipment.

1.18-Layer Megtron-7 Rigid PCB Produktübersicht & Definition

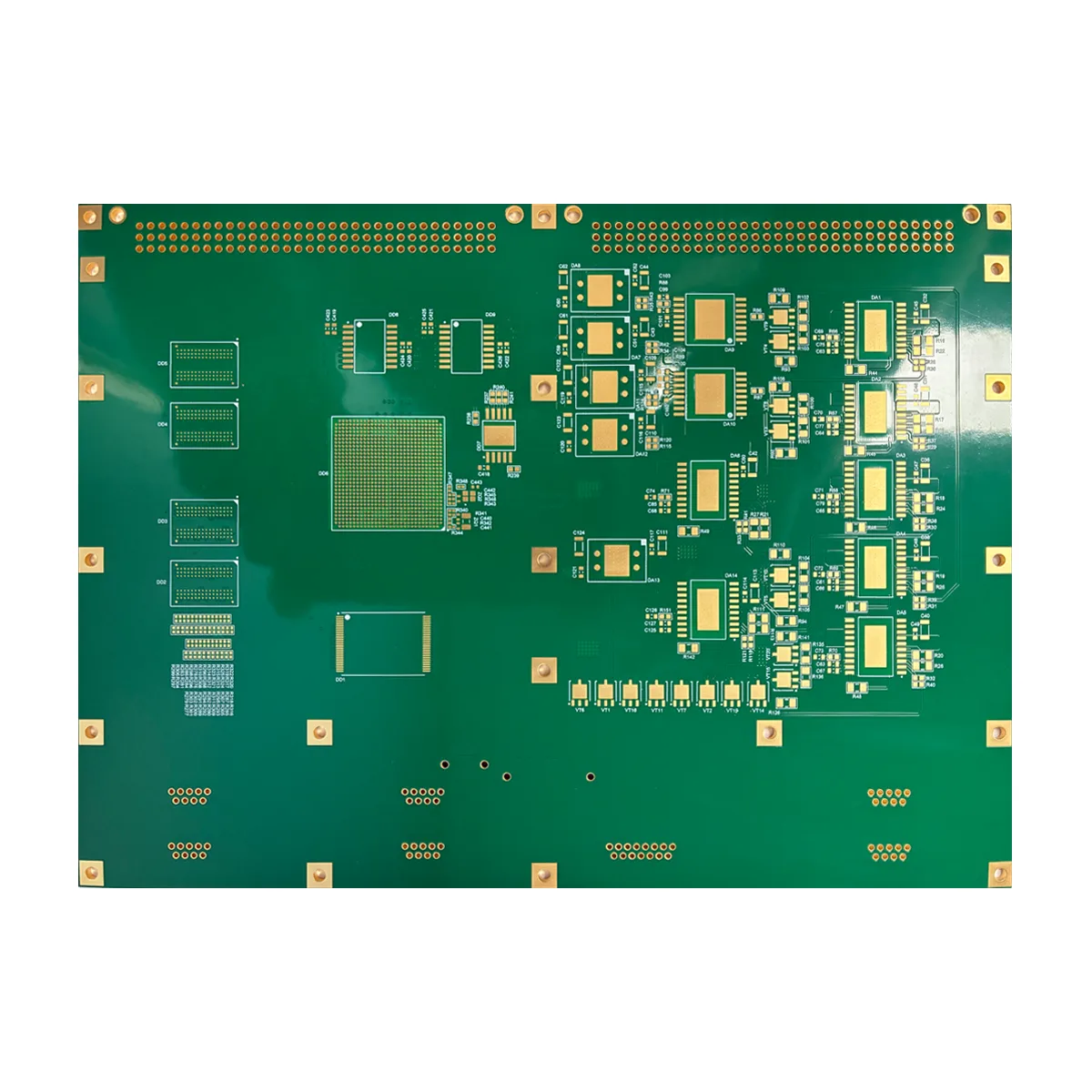

This product is an 18-layer rigid high-layer count PCB with a precisely controlled thickness of 1.86mm and overall dimensions of 165mm x 120mm. It utilizes industry-leading Megtron-7 high-speed low-loss laminate and features a 2-microinch (approx. 0.05µm) Elektrololes Nickel -Eintauchgold (ZUSTIMMEN) Oberflächenbeschaffung. This specification represents an advanced tier in leistungsstark Leiterplattenherstellung, designed for applications where signal integrity, Thermalmanagement, and reliability are paramount.

2. Überlegungen zum kritischen Design

Designing a successful 18-layer PCB, especially with high-speed materials like Megtron-7, requires careful attention to several core aspects:

-

Stack-up Design: A rational layer stack-up is critical for impedance control and crosstalk reduction. A typical 18-layer stack includes multiple signal, Leistung, and ground planes to ensure stable power distribution and clear signal return paths.

-

Impedanzkontrolle: High-speed signal transmission demands precise controlled impedance PCB Design. Trace width and spacing must be calculated accurately based on the Dk (Dielektrizitätskonstante) und Df (Dissipationsfaktor) of Megtron-7. We offer professional impedance calculation and simulation services.

-

Thermalmanagement: The 1.86mm board thickness and multi-layer structure necessitate effective thermal pathways in the design, such as using thermal vias to connect internal copper layers for efficient heat dissipation from components.

-

Hochdichte Interconnect (HDI) Überlegungen: While this is a standard through-hole design, careful planning of via types (blind, buried, through-hole) is essential at this layer count to minimize stub effects and optimize signal paths.

3. Wie es funktioniert & Struktur

A Multi-Layer-PCB functions like a highly integrated, three-dimensional “road network.” Electrical signals travel on copper traces (“roads”) on the surface and internal layers, with vertical connections between layers established through plated through-holes (“interchanges”). Dedicated power and ground planes provide stable voltage reference and noise shielding for the entire system. Das 18-layer rigid PCB is formed through a precise lamination process, bonding multiple core layers and prepreg sheets into a single, robust unit with excellent electrical properties. Its sophisticated PCB board structure is the foundation for implementing complex circuit functionalities.

4. Kernmaterialien & Key Performance

-

Materialien verwendet:

-

Laminieren: Megtron-7. This is a high-performance, low-loss copper-clad laminate from Panasonic, renowned for its stable dielectric constant (Dk ~3.3) and extremely low dissipation factor (Df ~0.001). It is optimized for applications above 10GHz and into millimeter-wave frequencies.

-

Kupferfolie: Utilizes Very Low Profile (VLP) or Reverse Treated Foil (RTF) to minimize “skin effect” losses caused by signal transmission on rough copper surfaces.

-

Oberflächenbeschaffung: Elektrololes Nickel -Eintauchgold (ZUSTIMMEN, 2u”). Provides a flat surface, ausgezeichnete Lötbarkeit, eine zuverlässige Kontaktschnittstelle (suitable for gold fingers), and long shelf life.

-

-

Outstanding Performance:

-

Superior Signal Integrity (UND): Exceptionally low signal loss ensures high-speed pulse waveforms remain undistorted.

-

Excellent Power Integrity (PI): Multiple dedicated power and ground planes offer very low power distribution network impedance and superior decoupling.

-

Hohe Zuverlässigkeit: The 1.86mm board thickness and premium materials deliver high mechanical strength, Wärmewiderstand, and long-term environmental stability.

-

Stable Impedance Control: Achieved through material consistency and precision manufacturing processes.

-

5. Product Classification

According to industry and IPC standards, this product is accurately classified as:

-

Für Schichtzahl: High-Layer Count PCB (typically defined as 10+ Schichten).

-

By Material Type: High-Speed High-Frequency PCB / Low-Loss PCB.

-

Durch Struktur: Starre PCB.

-

Nach Technologie: Controlled Impedance PCB, ENIG Finished PCB.

-

By Application Grade: Industrial Grade / Telecommunications Grade High-Performance PCB.

6. Schlüsselmerkmale & Vorteile

-

Premium Material: Built on Megtron-7 high-speed laminate, providing the physical basis for superior electrical performance.

-

High Complexity Capacity: Der 18-layer circuit board design allows for extremely complex and dense circuit layouts.

-

Precision Manufacturing: Strict tolerance control on the 1.86mm board thickness and consistent 2u” ENIG surface finish application.

-

Engineered for Speed: Optimized throughout—from design and material selection to processing—for Hochgeschwindigkeit digitale Schaltkreise Und RF/microwave circuits.

7. Überblick über den Produktionsprozess

Der high-layer count PCB manufacturing process is highly precise: Material Cutting → Inner Layer Imaging & Etching → Automated Optical Inspection (AOI) → Lamination (Pressing multiple inner layer cores with prepreg) → Drilling → Hole Metallization (Desmear, Electroless & Electrolytic Copper Plating) → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → Surface Finish (ZUSTIMMEN) → Profile Routing → Electrical Testing → Final Inspection. Each step requires stringent control, particularly layer-to-layer registration and impedance control.

8. Primäranwendungen & Anwendungsfälle

Das high-performance PCB board is the ideal choice for the following advanced applications:

-

High-Speed Communication Equipment: Core motherboards for 400G/800G optical modules, high-end routers, and switches.

-

Advanced Computing & Lagerung: Server motherboards, KI-Beschleunigerkarten, high-speed storage array (SSD) controller boards.

-

Precision Test & Measurement Instruments: Internal core boards for high-end oscilloscopes, spectrum analyzers, and signal generators.

-

Luft- und Raumfahrt & Defense Electronics: Processing units within radar systems and satellite communication payloads.

-

Advanced Medical Imaging Devices: High-speed data acquisition and processing boards for equipment like MRI and CT scanners.

Why Choose UGPCB for Your 18-Layer Megtron-7 PCBs?

We deliver more than just a Leiterplatte; we provide a complete solution encompassing DFM (Design für die Herstellung) Rezension, Präzisionsherstellung, Und Zuverlässigkeitstest. We possess deep expertise in every detail of high-layer count Leiterplattenfertigung, ensuring your design is translated into reality with the highest quality and reliability.

Kontaktieren Sie uns noch heute for a free technical assessment and a competitive quote for your project. Let UGPCB be the robust foundation for your high-end product’s success.