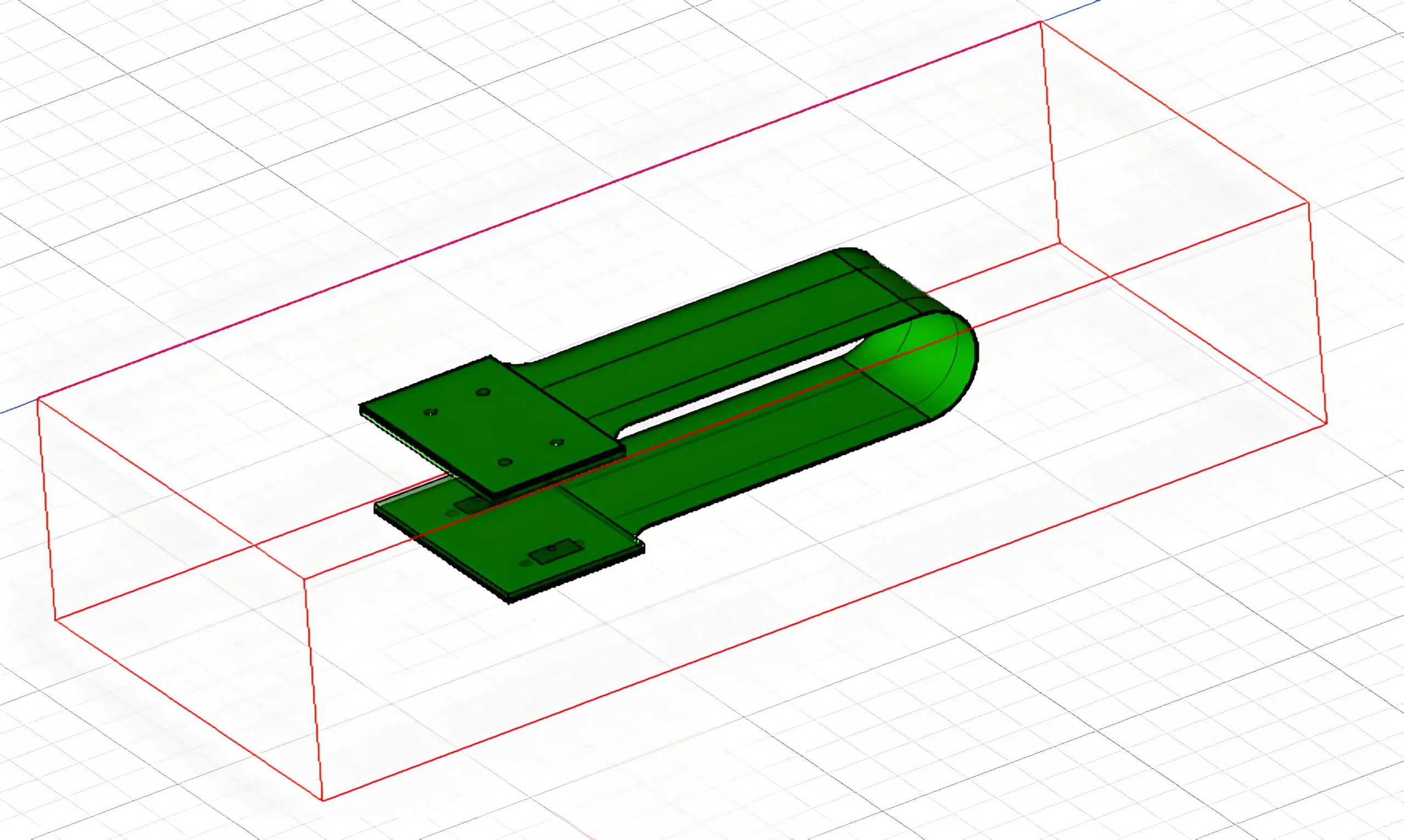

PCB-flex rigide: The Space-Saving Solution for High-Density Electronics

In the relentless pursuit of device miniaturization, réduction du poids, et une fiabilité améliorée, PCB-flex rigide have evolved from a technological novelty to an essential requirement for cutting-edge applications. This innovative structure masterfully combines the stable support of rigid PCBs with the deformation freedom of Flexible PCBs (FPC), granting PCB designers unprecedented 3D routing capabilities. With over a decade of expertise in PCB and PCBA manufacturing, UGPCB understands profoundly: choosing the right rigid-flex PCB design and manufacturer is a critical step towards product success!

Why Rigid-Flex PCBs are the Premier Choice for High-End Devices?

-

Revolutionary Space Utilization: Imagine circuit boards bending and folding like origami art within the device. This liberates the Z-axis dimension, enabling the integration of complex circuit systems – traditionally requiring multiple separate PCB, câbles, and connectors – into a single, compact assembly. Design freedom increases dramatically, while device size and weight decrease significantly.

-

Unmatched Connection Reliability: Connectors and cables are common failure points in traditional setups. Rigid-flex PCBs eliminate these physical interconnection points. Signals travel continuously within the flexible substrate, drastically boosting overall system stability and shock/vibration resistance. This makes them ideal for harsh environments like aerospace, defense, et dispositifs médicaux implantables.

-

Optimized Performance & Cost Balance: While the initial cost is higher than standard rigid PCBs, industry processes (MATÉRIAUX PCB, équipement, fabrication) continue to mature, steadily driving costs down. Crucially, rigid-flex PCBs integrate multiple components, simplify assembly, and improve yield. From a system perspective, the Total Cost of Ownership (TCO) becomes highly competitive for complex PCB and PCBA projects.

Plongée profonde: Propriétés physiques & Design Challenges of Rigid-Flex PCBs

Material Fusion: The Foundation and Challenge of Stability

The core of rigid-flex PCB manufacturing lies in the perfect bonding of dissimilar materials:

-

Rigid Areas: Typically use FR4 epoxy-glass laminate (CTE ≈ 14-17 ppm/°C).

-

Flexible Areas: Utilize Polyimide (PI, CTE ≈ 12-20 ppm/°C) or Polyester (ANIMAL DE COMPAGNIE) films.

-

Key Challenge: Managing differences in Coefficient of Thermal Expansion (CTE) between materials, ensuring strong adhesive interface bonds, and controlling dimensional stability during lamination. Poor bonding leads to delamination and cracking, severely impacting product lifespan.

Solution UGPCB: We rigorously select high-performance modified epoxy or acrylic adhesive systems. These materials are specially optimized to bridge the performance gap between FR4 and PI/PET, providing exceptional interlayer adhesion and stability under thermal cycling and mechanical stress. Material selection is strictly validated against IPC-6013D and IPC-2223B standards.

Stress Management: The Invisible Challenge in 3D Space

The unique 3D configuration of rigid-flex PCBs subjects them to multi-axial stresses during application (par ex., repeated flexing, dynamic movement):

-

XY-Axis Stress: Tensile/compressive forces within the board plane.

-

Z-Axis Stress: Interlayer peeling forces, especially critical in bend transition zones (Bend Radius

Ris key!). An insufficient bend radius or poor design can cause copper fracture or coverlay wrinkling. -

Key Formula – Minimum Bend Radius (

Rmin) Rule of Thumb: For dynamic flexing applications,Rmin ≥ 10 * t(oùt= total flex layer thickness). For installation bends (one-time or very few bends),Rmin ≥ 6 * t. Precise calculation requires considering copper weight, PI thickness, layer stackup, and specific material ductility.

UGPCB Advantage: Our engineering team excels in Finite Element Analysis (Fea) simulation. We predict and optimize stress distribution in bend areas during the design phase, ensuring products meet the most stringent flex life requirements (par ex., >100,000 dynamic bend cycles).

Alt tag suggestion: rigid-flex-pcb-stress-analysis-bend-region-fea (Image showing FEA stress contour plot highlighting critical zones in bend transition)

Traiter la complexité: High Barrier Creates High Value

Rigid-flex PCB production involves significantly more steps than standard rigid or pure flex boards, representing the pinnacle of precision manufacturing:

-

Lengthy, Multi-Step Process: Requires alternating processing of rigid and flex zones, involving multiple laminations, forage, placage, coverlay application, and contour routing (milling + laser cutting).

-

Extreme Registration Accuracy: Different materials exhibit varying dimensional change rates during processing, demanding precise compensation for layer-to-layer alignment.

-

Yield Challenges: Statistics show a typical 4-layer rigid-flex PCB takes 5-7 times longer to manufacture than a standard rigid PCB of the same layer count. This complexity directly leads to higher production costs and demands exceptional technical capability from the PCB manufacturer.

UGPCB Core Capability: A decade of industry focus has enabled us to establish dedicated rigid-flex PCB production lines and process control systems. From high-precision lamination presses (with temperature/pressure profiling) to specialized plating lines for flex materials (ensuring uniform hole copper), to Laser Direct Imaging (ILD) and laser cutting, all equipment is optimized for rigid-flex characteristics. This ensures high yields (>85%) and batch consistency for reliable Assemblage PCBA.

Vast Applications: Where Rigid-Flex PCBs Excel

The unique value proposition of rigid-flex PCBs makes them the “invisible champion” in these demanding fields:

-

Aérospatial & Défense: Missile guidance systems, satellite payloads, airborne radar/communication equipment – requiring extreme reliability, lightweighting, and resistance to high shock/vibration.

-

High-End Medical Devices: Endoscopes, stimulateurs cardiaques, neurostimulators, portable diagnostics – where miniaturization, biocompatibilité, and long-term implant reliability are paramount.

-

Flagship Consumer Electronics: Hinge area circuits in foldable smartphones, ultra-thin laptop hinge connections, TWS earbud charging case/interconnect, action cameras, high-density wearables – pursuing ultimate space savings and sleek form factors.

-

Industriel & Électronique automobile: Industrial robot joint wiring, automotive camera modules, ADAS sensors, EV Battery Management Systems (Bms) – needing to withstand vibration, cyclisme thermique, and tight space constraints.

UGPCB: Your Trusted Partner for Advanced Rigid-Flex PCB Design & Fabrication

As a professional PCB and PCBA supplier with over 10 years of industry experience, UGPCB considers rigid-flex technology a core competency. We are committed to providing customers with a seamless, one-stop solution from design to volume production.

Our Core Advantages

-

Proven Design Expertise: Our engineering team masters rigid-flex design standards like IPC-2223 and IPC-6013. We swiftly solve key challenges: bend radius calculation, stackup planning, sélection des matériaux, stress relief design – mitigating failure risks and shortening your Time-to-Market (TTM).

-

Robust Manufacturing Prowess: Equipped with dedicated rigid-flex production lines. We strictly control critical processes: material sourcing (RoHS & custom eco-compliance), multi-layer precision alignment (≤±50μm), controlled lamination, microvia processing (laser/mechanical drilling). Ensures products meet high-reliability demands (HALT/HASS testing supported).

-

Balanced Speed & Coût: Optimized processes and scaled production significantly reduce lead times compared to industry averages, delivering cost-effective, high-end PCB and PCBA solutions.

-

Cross-Industry Application Experience: Products widely used in communication base stations, industrial control systems, électronique automobile (especially EV powertrain systems), high-end power modules, smart security devices. Exported to premium EU/US markets with globally recognized quality.

-

Stringent Quality System: A comprehensive quality control system spans IQC to OQC, covering raw materials, in-process checks, and final product inspection. Guarantees stable performance and reliable quality for every rigid-flex PCB delivered.

Agissez maintenant & Unlock Your Product’s Potential!

Facing intricate electronic design challenges? Choosing UGPCB as your rigid-flex PCB partner means choosing confidence and success. We deliver not just circuit boards, but a solid manufacturing foundation for your innovation.

Have specific project needs or questions?

-

📧 Send RFQ to: sales@ugpcb.com

-

📞 Call our Experts: +86-135 4412 8719

-

💬 Chat Online with Sales/Engineer

Don’t hesitate! Our sales and engineering team will provide a competitive quote dans 24 heures. Let UGPCB empower your electronics innovation leadership with superior rigid-flex PCB design and manufacturing!