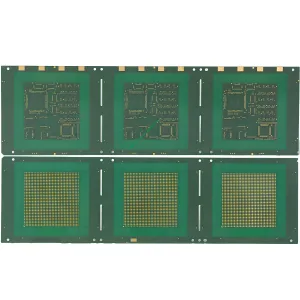

Présentation du produit: What is an HDI IC Substrate Board?

An HDI IC Substrate Board is a critical, high-end circuit imprimé engineered specifically for semiconductor package interconnection. It acts as the essential interface, providing electrical connectivity, distribution d'énergie, and mechanical support between a finely-pitched silicon die and a standard motherboard PCB. UGPCB delivers high-reliability, advanced HDI IC Substrate manufacturing, meeting the stringent demands of applications from consumer electronics to high-performance computing.

This board, built with SI10U material in a 6-couche (2+2+2) construction and a slim profile of 0.6mm, exemplifies state-of-the-art IDH technologie. With a 35x35mm unit size, it features a 0.1mm minimum laser via diameter, 30μm minimum trace width / 70μm minimum spacing, et Énipique (Nickel électrolaire à l'immersion du palladium électrolaire) finition de surface, making it an ideal solution for packaging high-speed, haute fréquence, and highly integrated chips.

In-Depth Analysis: Conception, Fonction, and Applications

Core Definition & Principe de fonctionnement

The HDI IC Substrate is designed to “fan-out” the dense array of micro-bumps from a semiconductor die, redistributing the connections to a larger pitch compatible with standard Assemblage de circuits imprimés processes like BGA (Tableau de grille à billes) montage.

The working principle follows this chain: Die → Microbumps → HDI IC Substrate (for signal redistribution & interconnection) → Solder Balls (BGA/CSP) → Mainboard PCB. It is pivotal for signal integrity, power delivery, et gestion thermique.

Key Design Considerations

-

Stack-up & Contrôle de l'impédance: The 6-layer (2+2+2) build-up is a classic design for high routing density. Precise impedance calculation (typically 50Ω single-ended or 100Ω differential) is crucial for signal integrity.

-

Micro-via Reliability: 0.1mm (100µm) laser-drilled micro-vias are key for interconnect density. Via shape, placage en cuivre, and fill process must be optimized for thermal cycle reliability.

-

Fine-Line Fabrication: 30μm trace width and 70μm spacing are core metrics of process capability, directly impacting I/O density and electrical performance.

-

Thermal & Mechanical Management: The selection of SI10U material considers its Coefficient of Thermal Expansion (CTE) matching with silicon to minimize thermal stress and enhance product longevity.

Primary Materials & Caractéristiques de performance

-

Core Material: SI10U. A high-performance laminate offering low dielectric constant (Ne sait pas), low dissipation factor (Df), high glass transition temperature (Tg), et excellente stabilité dimensionnelle, ideal for high-speed, high-frequency applications.

-

Masque de soudure: PSR-4000 AUS308. A high-resolution, high-reliability Liquid Photoimageable Solder Mask (LPSM) that provides precise coverage, excellent insulation, et résistance chimique.

-

Finition de surface: Énipique. This finish deposits sequential layers of Nickel, Palladium, and Gold. Nickel acts as a diffusion barrier, Palladium prevents nickel corrosion, and the thin gold layer offers superior solderability and wire-bonding capability, perfect for fine-pitch pads.

-

Performance Summary: Haute densité, grande vitesse, haute fiabilité, Excellente gestion thermique, and superior signal integrity.

Classification & Scénarios d'application

HDI IC Substrates are categorized by technology and application:

-

By Technology: With core (par ex., this 6L build-up) or coreless types.

-

Par candidature:

-

Advanced Processors: Processeur, GPU, AI accelerator chips requiring maximum routing density and signal speed.

-

Mobile & RF: Smartphone Application Processors (AP) et modules RF, where miniaturization and thin profiles (0.6mm) are critical.

-

Mémoire: Interface substrates for High Bandwidth Memory (HBM).

-

Networking & Automobile: High-speed switch chips and ADAS domain controllers.

-

UGPCB’s Manufacturing Process & Assurance qualité

UGPCB’s production integrates leading-edge processes compliant with IPC standards:

-

Forage au laser: UV laser systems create precise 0.1mm micro-vias.

-

Placage & Via Fill: Advanced pulse plating ensures complete via filling for reliable interconnects.

-

Advanced Imaging: High-end exposure systems and high-resolution dry film achieve 30/70µm line definition.

-

Laminage: Precise alignment and pressing of multiple core layers and prepreg (Pp).

-

Finition des surfaces: Application of the Énipique coating for optimal solderability.

-

Tests complets: Utilizes AOI (Inspection optique automatisée), test de sonde volante, and impedance testing to guarantee compliance.

Notre one-stop PCB service capability extends from Substrat IC fabrication to subsequent Assemblage SMT et essai, offering a complete packaging solution.

Why Choose UGPCB for Your HDI IC Substrate?

-

Advanced Process Capability: Proven expertise in 30/70μm trace/space et 0.1mm micro-via technologie.

-

Materials Expertise: In-depth knowledge of advanced materials like SI10U to recommend optimal solutions.

-

Uncompromising Quality: Stringent, automotive-grade quality control throughout the entire process.

-

Solution à guichet: We are more than a PCB fabricator; we are your PCBA partner, offering design support, fabrication, et assemblage.

-

Expert Support: Dedicated engineering team provides DFM (Conception de la fabrication) analysis and technical consultation.

Obtenez votre solution personnalisée maintenant

Whether you are developing the next HPC platform, 5Infrastructures G, ou ADAS system, UGPCB’s professional HDI IC Substrate manufacturing et Services d'assemblage de PCBA are your foundation for success.

Contact us today for a free technical consultation and quote! Let our experts help you enhance product performance through optimized IC substrate design and reliable Fabrication de circuits imprimés processus.