Introduction to Rogers RO4350B

Rogers RO4350b is a hydrocarbon / ceramic laminate with a dielectric constant of 3.48. It meets the requirements of commercial equipment manufacturers for printed circuit boards.

Advantages of Rogers RO4350B

Avantages clés

- Faible perte RF

- Faible fluctuation constante diélectrique avec la température

- Faible coefficient de dilatation thermique sur l'axe Z

- Coefficient de dilatation dans une plaque basse

- Tolérance de faible permittivité

- Stable Electrical Characteristics at Different Frequencies

- Easy Mass Production and Multi-Layer Mixing with FR4, High Cost Performance

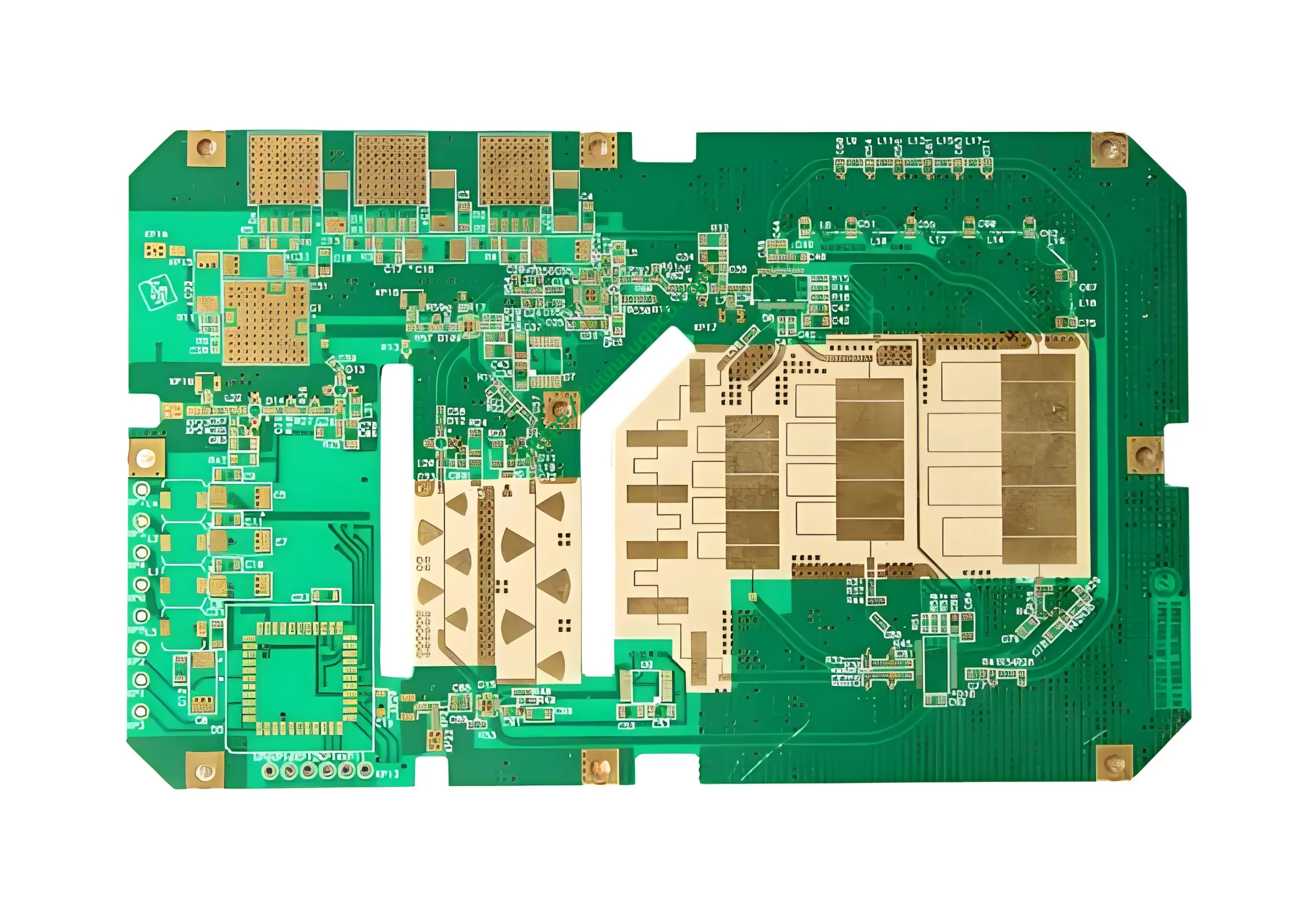

Rogers RO4350B Hybrid PCB

The Trend of Hybrid PCBs

The hybrid of FR4 and high-frequency PCB materials is becoming increasingly common, due to the limited compatibility between FR4 and most high-frequency PCB materials.

Composite PCB Construction

The composite PCB, made of common FR-4 plate, P-chip, and special board (such as ceramic board, PTFE, hydrocarbon, polyphenylene oxide, et autres matériaux) and P-chip, can fulfill the requirements of high-frequency signal transmission and high-security signal transmission. It allows for the design of RF circuits on the PCB. En même temps, mixed pressing can reduce the use of high-speed and high-frequency PCB materials, thereby lowering production costs.

Production Capabilities

Actuellement, UGPCB produces Rogers RO4350b + FR4 type composite laminates in batch.