UGPCB: An Industry Leader in Rigid-Flex PCB Manufacturing Capabilities

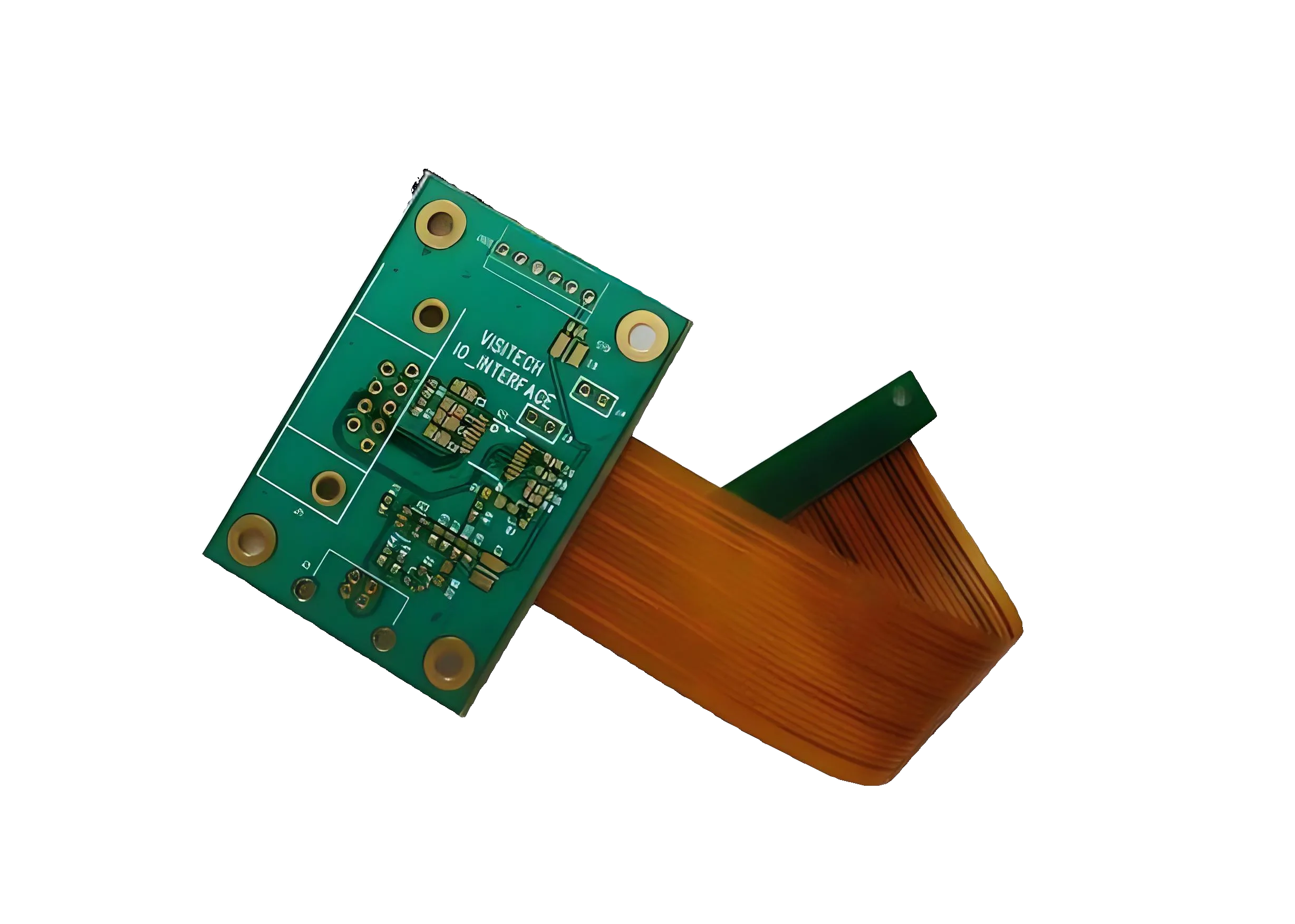

今日の急速に進化するエレクトロニクス業界では, the growing demands of 5G communications, 人工知能, モノのインターネット (IoT), 医療用電子機器, and aerospace have made 剛体PCB an indispensable core component in high-end electronic devices. 先頭として PCBメーカー, UGPCB has set an industry benchmark in Rigid-Flex PCB process capabilities with its sophisticated engineering expertise and advanced production equipment, delivering high-performance and highly reliable solutions to global customers.

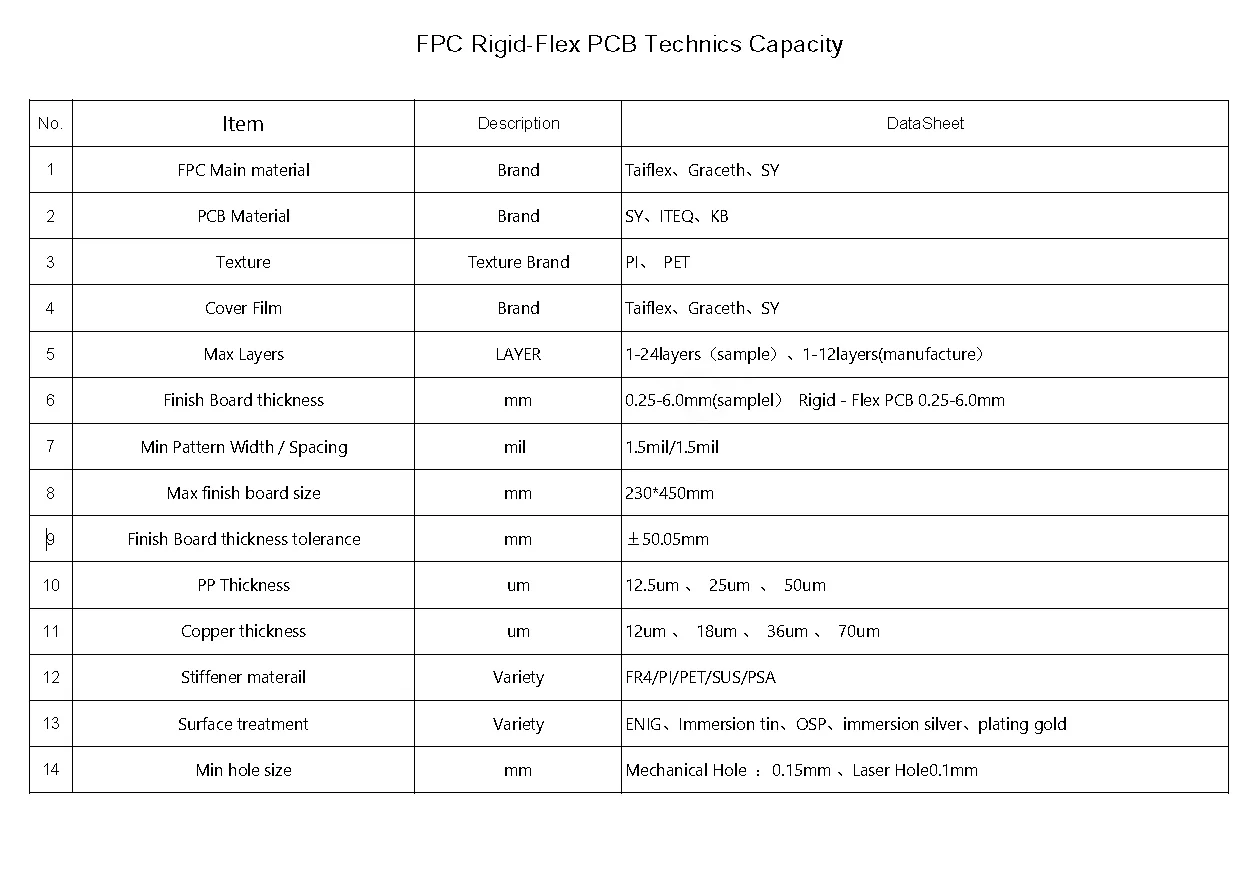

Core Technical Parameters: Defining High Industry Standards

UGPCB’s Rigid-Flex PCBs feature a range of precise technical parameters that meet the most demanding application requirements:

-

レイヤー数: サポート 4 に 24 layers of combined flexible and rigid PCBs, enabling high-density interconnect (HDI) designs to accommodate complex circuitry.

-

トレース幅/間隔: As low as 1.5mil/1.5mil, with precision controlled within ±5%, 高周波信号の完全性を確保します.

-

Board Thickness Control: Overall thickness ranges from 0.25mm to 6.0mm, with independent control for flexible and rigid sections.

-

インピーダンス制御: Tolerances as tight as ±5%, ensuring quality signal transmission at frequencies above 10GHz.

-

Bend Endurance: Flexible sections withstand over 100,000 bending cycles, with some products achieving up to 500,000 dynamic flex cycles (R=5mm, 180° reciprocating).

-

動作温度: Stable performance in extreme environments from -55°C to +150°C, with zero failures after 1,000 サーマルショックサイクル.

Advanced Process Technologies: Breaking Through Traditional Manufacturing Barriers

Through continuous technological innovation, UGPCB has overcome multiple challenges in Rigid-Flex PCB manufacturing:

-

Laser Drilling Technology: Utilizes advanced レーザー穴あけ to achieve 100μm microvias with smooth, burr-free hole walls, significantly improving multilayer interconnect reliability.

-

Adhesive-Free Lamination: Eliminates bubbles and delamination in flexible areas, with bend radii controllable within 0.5mm, greatly enhancing product durability and reliability.

-

“Step Copper” Technology at Rigid-Flex Junctions: Implements a gradual copper thickness transition from 0.5oz to 1oz, reducing bending stress by 38% and effectively preventing traditional “white spot” cracks.

-

Plasma and Chemical Surface Treatment: Achieves peel strength >1.2N/mm at rigid-flex interfaces, 業界標準をはるかに上回っている.

-

Symmetrical Stack-Up Compensation Algorithm: Uses AI simulation with 200,000 iterative calculations to control warpage to ≤0.3%, compatible with 0.4mm pitch BGA assembly.

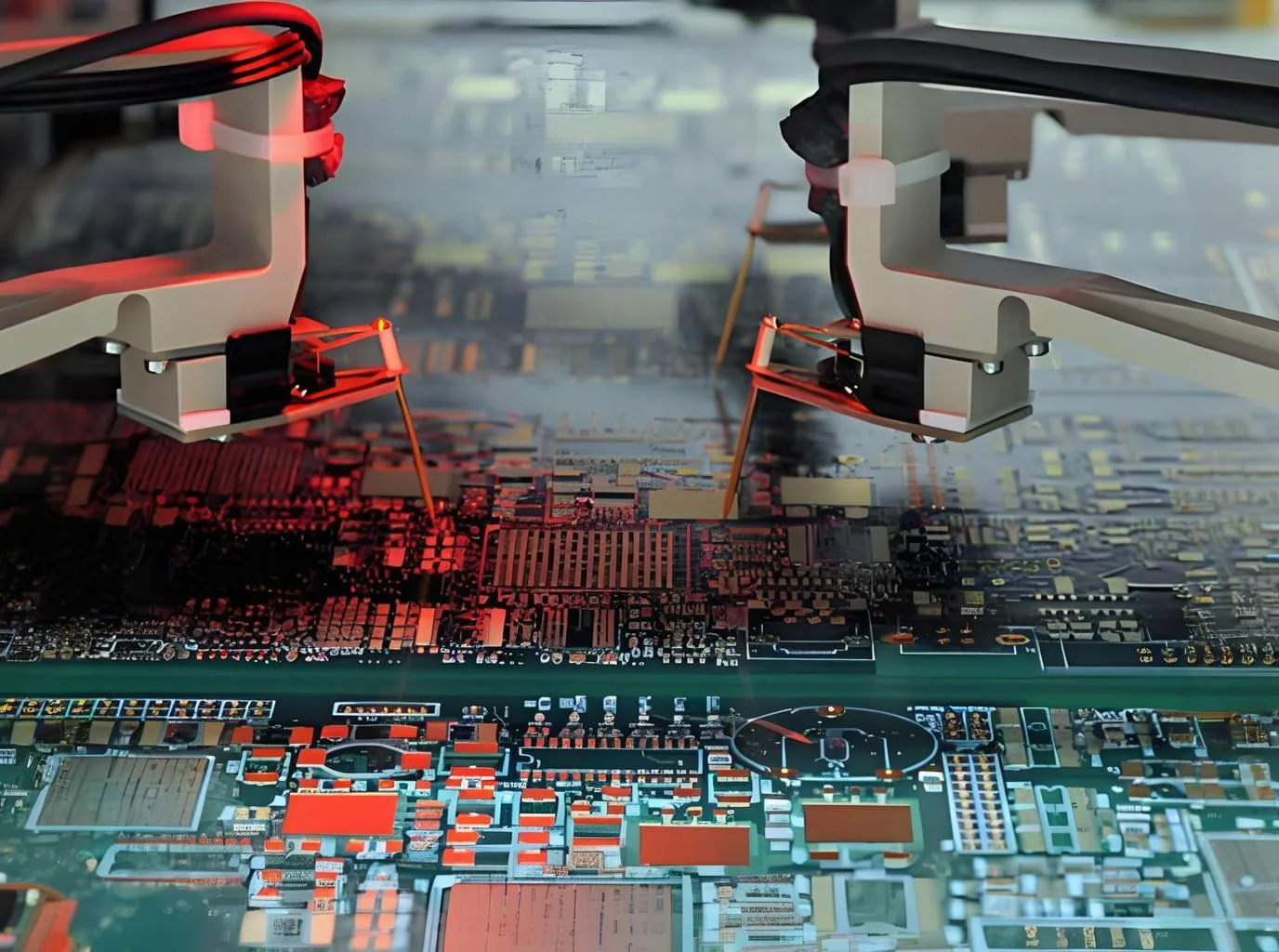

Exceptional Quality Control System

UGPCB has established a comprehensive quality control system to ensure high reliability and consistency:

-

Full-Process AOI + AI Defect Prediction: 雇用する 自動光学検査 (あおい) and artificial intelligence for defect prediction, achieving a yield rate exceeding 98%.

-

Flying Probe and 4-Wire Milliohm Testing: 用途 4-wire milliohm testing in flexible areas to ensure zero cold joints in RF and power lines.

-

Full-Process MES Traceability: Each board comes with an “electronic birth certificate,” enabling precise post-sale traceability to batch and machine for rapid issue resolution.

Diverse Application Fields

UGPCB’s Rigid-Flex PCBs are widely used across multiple high-tech industries:

| アプリケーションフィールド | Specific Products | Solution Advantages |

|---|---|---|

| 家電 | Foldable phones, AR/VR devices, TWS earphones | Reduces connectors and solder joints, decreasing failure rates by 70% in vibration environments |

| カーエレクトロニクス | Battery Management Systems (BMS), リダー | AEC-Q100 certified, survives 1,000 thermal shock cycles from -55°C to +150°C with zero failures |

| 医療機器 | Capsule endoscopes, portable diagnostic equipment | Uses biocompatible materials, IEC60601 certified, operates continuously for 72 hours in gastric acid environments |

| 航空宇宙 | Satellite communication modules, avionics systems | Polyimide/copper-nickel alloy composite boards, stable in extreme temperatures from -180°C to +120°C |

| 産業管理 | Industrial robots, semiconductor test equipment | Supports 30° to 180° free bending, increases internal space utilization by over 40% |

Customer Cases: Enabling Client Success

UGPCB collaborates with industry leaders to overcome technical challenges:

-

AR Glasses Project: Developed a 12-layer Rigid-Flex PCB for a leading AR glasses manufacturer, reducing mainboard thickness from 2.1mm to 0.9mm, cutting device weight by 18g. RF traces embedded directly in the flexible area resulted in VSWR <1.3 そしてa 7% improvement in antenna efficiency.

-

TWS Earbuds Project: Supplied an 8-layer Rigid-Flex PCB for a top-three global TWS earbud brand, compressing mainboard thickness from 1.05mm to 0.65mm, increasing yield from 72% に 96%, and reducing signal delay per device by 0.8ns.

-

Medical Device Project: Customized a 16-layer Rigid-Flex PCB for an international medical giant for use in a portable ultrasound diagnostic device, reducing equipment size by 40% and improving anti-interference performance by 60%.

Corporate Strength and Production Capacity

UGPCB possesses strong technical expertise and production capabilities:

-

Production Bases: Two smart factories located in Shenzhen and Jiangxi, with a monthly capacity of 350,000 平方フィート.

-

R&D投資: 8% of annual revenue is invested in exploring innovative process technologies and acquiring advanced equipment.

-

装置: Features a 2,000㎡ Class 1000 cleanroom equipped with German LPKF laser systems and Israeli Camtek inspection systems.

-

迅速な応答: Offers 24-hour quick-turn PCBプロトタイピング services and provides one-stop solutions from design review to volume production and PCBAアセンブリ.

結論: Summary of UGPCB’s Advantages

UGPCB offers comprehensive advantages in the Rigid-Flex PCB manufacturing sector:

-

技術的リーダーシップ: Capabilities include 1.5mil/1.5mil fine-line fabrication, 0.1mm micro blind via laser drilling, and advanced multilayer lamination.

-

Reliable Quality: Certified to multiple international standards, with full-process quality monitoring ensuring product yields over 98%.

-

Broad Applicability: 製品は家庭用電化製品に広く使用されています, 自動車, 医療機器, 航空宇宙, and other high-tech fields.

-

コスト効率: Although initial costs may increase by 15%, overall assembly steps are reduced by 30%, and lifecycle costs decrease by 20% due to lower rework rates.

UGPCB is committed to providing global customers with superior Rigid-Flex PCB solutions through technological innovation and process upgrades, helping clients gain a competitive edge in the market. No matter your industry, if your product requires circuit board solutions that push the limits of space and performance, UGPCB is your most trusted partner.

To learn more about UGPCB’s Rigid-Flex PCB manufacturing capabilities, contact our expert team for the latest technical information and customized solutions.

UGPCBのロゴ

UGPCBのロゴ

微信

WeChat で QR コードをスキャンします