アナログの領域で 回路設計, 運用アンプ, 精密抵抗器, そして、コンデンサはしばしばスポットライトを主張します. しかし、システムパフォーマンスの制限の真の決定要因は、舞台裏で働く隠された首謀者です: の プリント基板 (プリント基板). このサイレントファンデーションは、統治中にすべてのコンポーネントを搭載しています 信号の完全性, ノイズ抑制, そして システムの信頼性 トレースのすべてのミリメートルを通して, 各誘電層, そして、すべての接地決定.

PCB材料科学: FR評価を超えて高周波性能を解読します

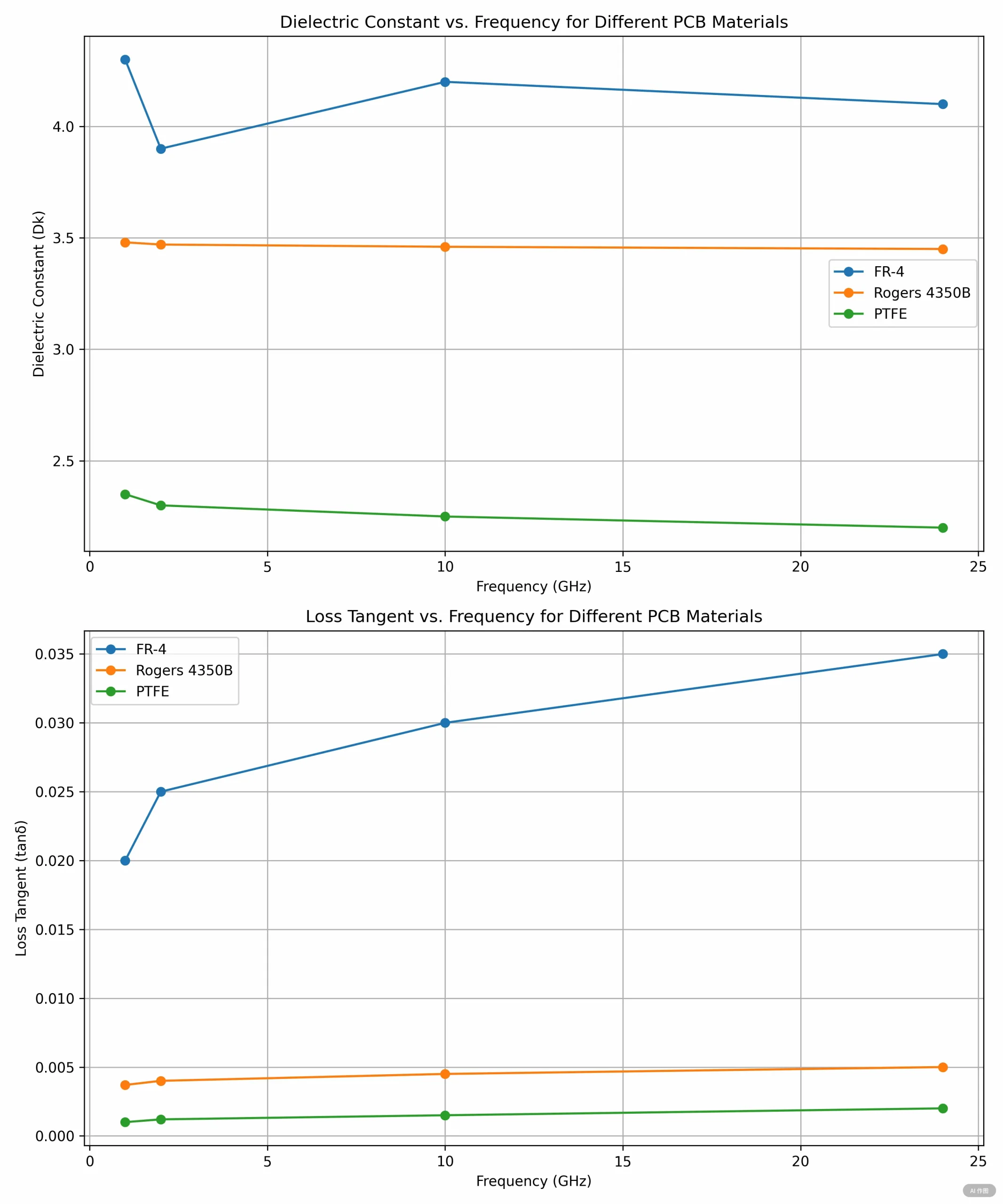

議論するとき プリント基板材料, FR-4の可燃性評価は、単なるプロローグです. 高速アナログ回路用, 誘電率 (DK) そして 損失係数 (タンδ) 目に見えないハンドシグナルシグナルの運命です.

信号伝播速度 (v) によって決定されます:

v = c / √(ε_r)

ここで、 * c * =光の速度, E_R =相対誘電率. FR-4のε_Rは間に変動します 4.2-4.8, 原因 5% 信号遅延変動. もっと批判的です, その損失特性 - 10GHzで, 標準のFR-4は、tanδ= 0.02を示します, と同等 0.5インチあたりのDB信号損失.

湿度温度相互作用 精度の回路で特に致命的であることが証明されています:

-

1% 水分吸収により、FR-4表面抵抗が3桁減少します

-

15% 85°Cシフトフィルター中心周波数を壊滅的にシフトするDKドリフト

専門家の洞察: Rogers 4350bを使用した医療PCB (E_R = 3.48±0.05) 維持する <2% -40°Cから +150°CへのDK変動 - 生命維持監視機器にとって重要.

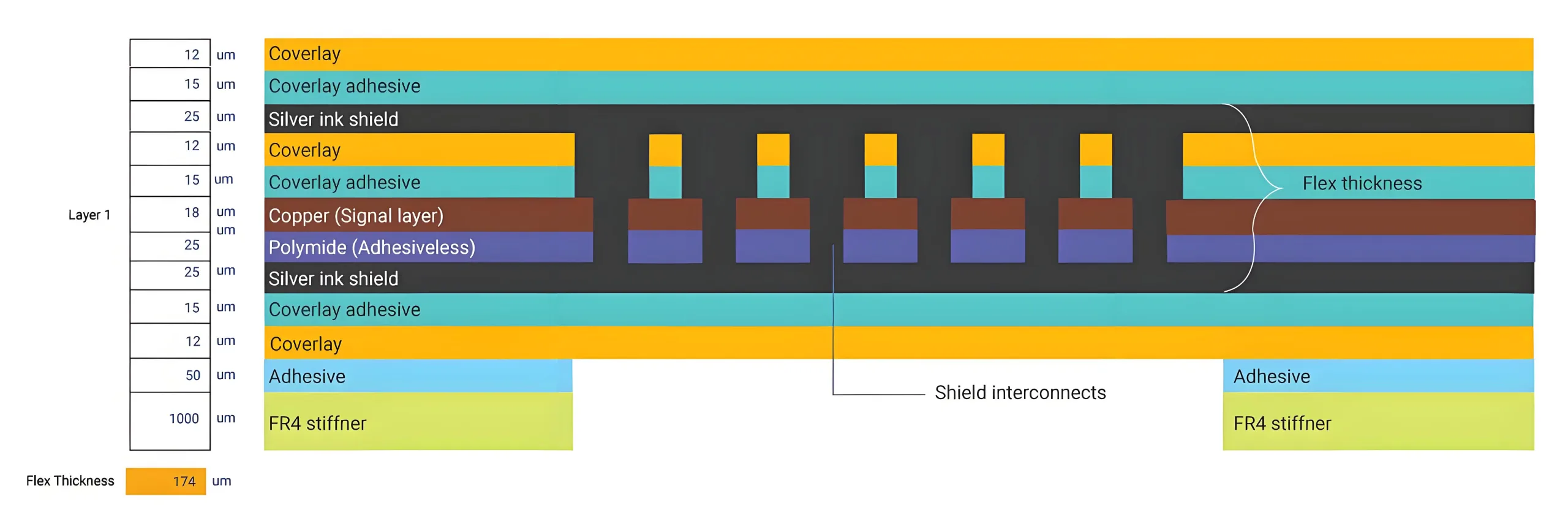

PCBスタックアップアーキテクチャ: エンジニアリング現在のパス & EMIシールド

単一/二重層の制限

10MHzシグナルを超えて, 1.6MM両面ボードは、接地層の弱点を明らかにします. 層間容量:

C = (ε_0 * ε_r * A) / d

標準の1.6mmボードは、35pf/in²のみを達成します >100MHzノイズ抑制.

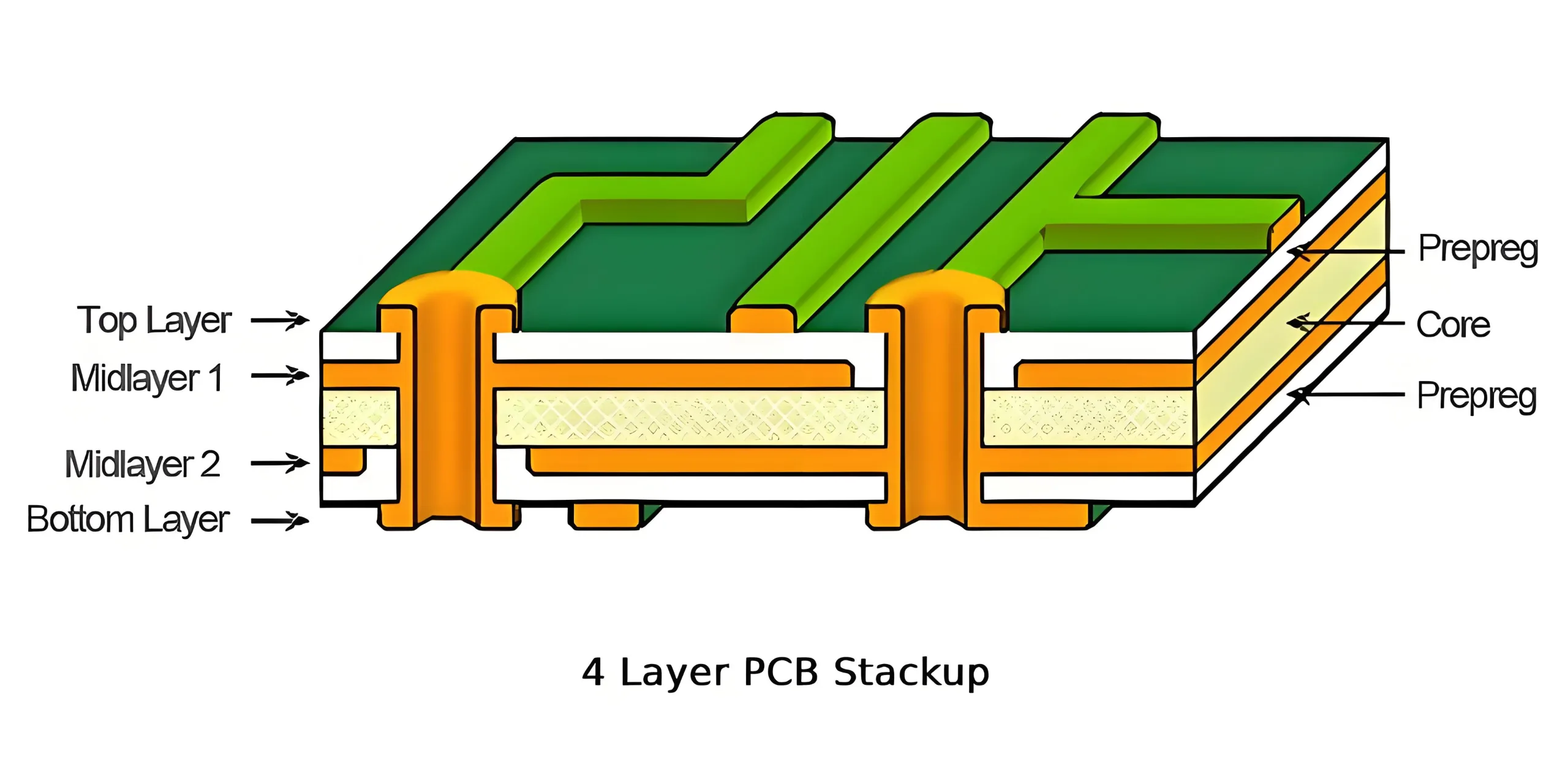

4層スタックアップ革命

専用の電力/地上飛行機はインピーダンス制御を変換します:

-

0.2MM誘電体は280pf/IN²に容量を高めます

-

グランドプレーン抵抗は、単一層の1/100に低下します

-

放射ノイズの減衰は40dB増加します

検証データ: UGPCB ラボテストでは、4層の設計が78μVPPから12μVPPにオペアンプの出力ノイズを減らすことを示しています - 85% 改善.

検証データ: UGPCB ラボテストでは、4層の設計が78μVPPから12μVPPにオペアンプの出力ノイズを減らすことを示しています - 85% 改善.

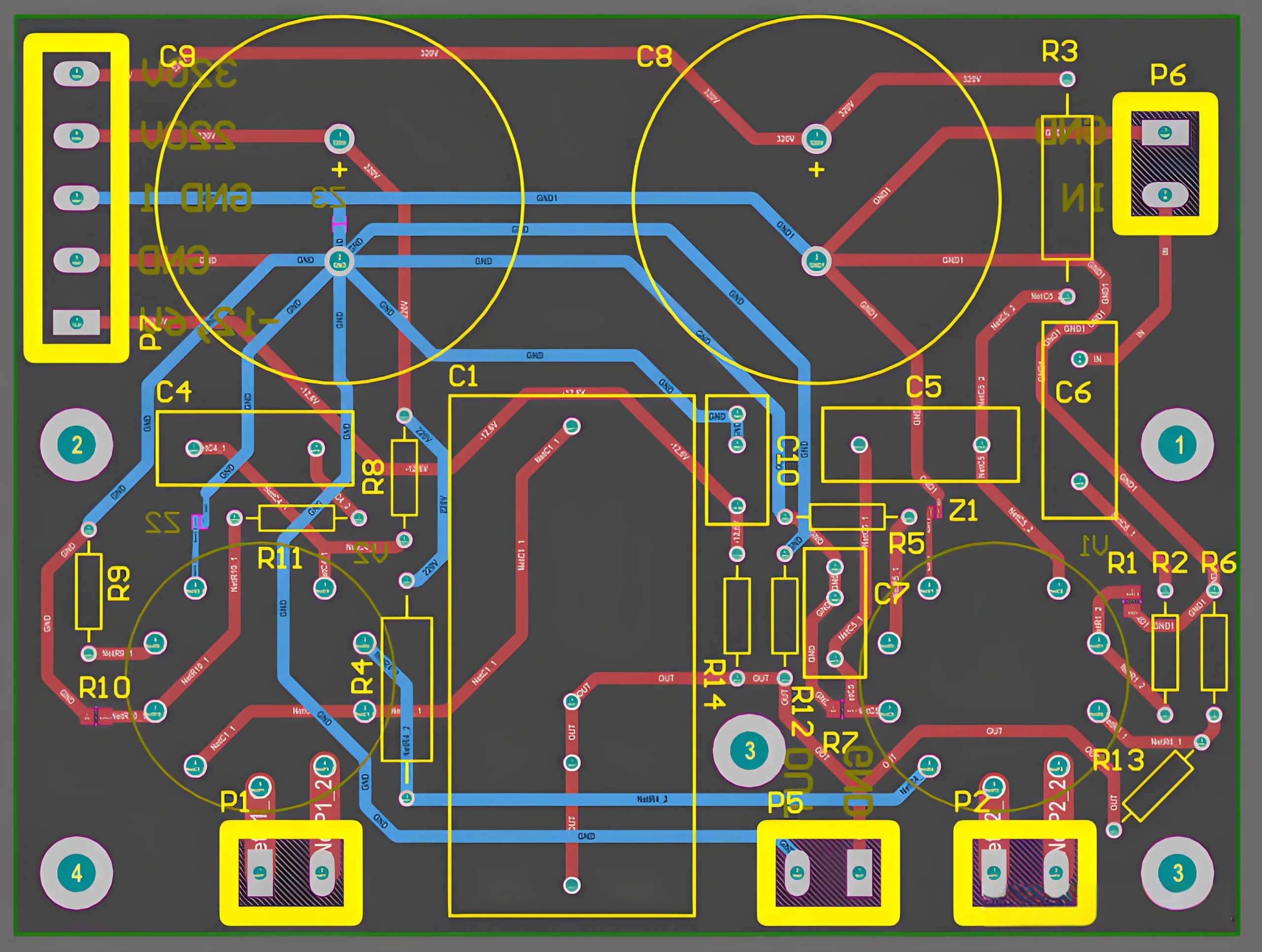

接地戦略: アナログデジタル境界の確立

平面分離の臨界

重複するデジタル/アナログの地上飛行機は、容量性ノイズチャネルを作成します:

C_coupling = (ε * A_overlap) / d

1.6mmボードの0.1mm²のオーバーラップでも、0.3pfの結合容量を生成します。100MHzクロックノイズをμVレベルのアナログ信号に注入するのに十分です。.

星の接地原理

単一点接地は、数学的に接地ループを排除します:

V_noise = -dΦ/dt = -2πf * B * A

どこ B =磁束密度, あ =ループ領域. ある時点での収束パスは、ループ領域を最小限に抑えます.

コンポーネント周波数マスキング: 抵抗器がインダクタになるとき

抵抗性寄生虫

0805 フィルム抵抗器には、約2NHの寄生インダクタンスが含まれています. 100MHzで:

X_L = 2πfL = 1.26Ω

典型的な抵抗値を超えます, 回路の動作を根本的に変更します.

容量性自己共感トラップ

コンデンサのインピーダンスが続きます:

|Z| = √[R_ESR² + (X_L - X_C)²]

標準の10μFタンタルコンデンサは、300kHzで自己共同です, 10MHzで0.1μFセラミックによってアウトパフォームされています:

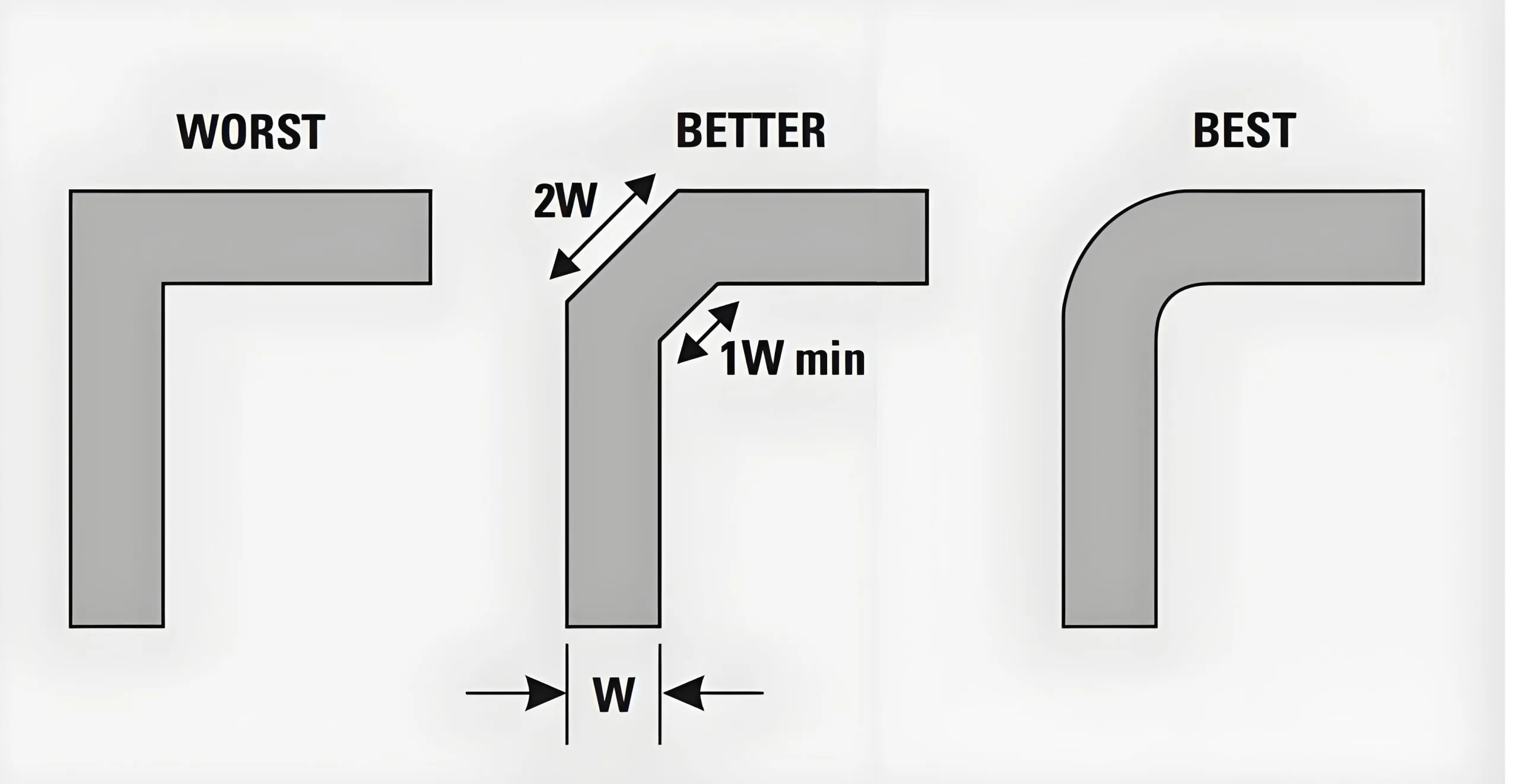

ルーティングジオメトリ: 90°曲げのem catastrophe

右角痕跡は、高速で隠されたアンテナとして機能します PCBレイアウト:

-

トレースの長さを効果的に増やします 26%

-

コーナー容量は、インピーダンスの不連続性を引き起こします

-

45°の曲げよりも効率的に30dBを放射します

Viasは等しい危険性を示します. 0.3mm Viaの寄生インダクタンス:

L ≈ 5.08h [ln(4h/d) + 1] (pH)

ここで、 * h * =ボードの厚さ (mm), *d* =穴の直径 (mm). 1GHzで, 1.6mmのシングルボードは1.6Ωのリアクタンスを生成します.

究極の防御: ナノクリーニングからファラデーエンクロージャーまで

イオン汚染制御

高インピーダンスノードには、以下のイオン残基が必要です:

<1.56 μg/cm² (IPC J-STD-001 Class 3)

DI水による超音波洗浄は達成されます <0.3μg/cm².

EMIシールド効果

ファラデーケージのパフォーマンスが続きます:

SE(dB) = 20log[(Z_0)/(4Z_s)] + 20log(e^(t/δ))

どこ d =肌の深さ. 1MMアルミニウムは、1GHzで120dB減衰を提供します, しかし、0.1mmのギャップはこれを30dBに分解します.

目に見えない建築家の啓示

データは驚くべき真実を明らかにします: 68%+ 回路の障害は、PCB設計上の欠陥に由来します. かつては単なるコンポーネントキャリアと見なされます, PCBは実際には ミッションクリティカルなシステムアーキテクト.

10GHz回路で:

-

FR-4誘電損失は、15dBの信号エネルギーを消費する可能性があります

-

0.5MMグラウンドジャンプは300mVのグラウンドバウンスを誘導します

-

顕微鏡フラックス残基は漏れ経路を作り出します

設計革命は、パラダイムシフトから始まります: コストアイテムからPCBを再分類します コア機能要素. 次のオペアンプをレイアウトするとき:

-

その0.1Bノイズの改善は、ラミネートDK値に存在します

-

これらの3PSタイミングマージンは、地上の平面厚に存在します

これを高めます “目に見えないアーキテクト” バックステージからセンターステージまで, アナログサーキットはパフォーマンスの障壁を打ち破ります.

UGPCBのロゴ

UGPCBのロゴ