Ultra-Thin Single-Sided Flex PCB with Aluminum Stiffener 製品の概要 & 意味

In the pursuit of thinner, lighter, and more reliable electronic devices, UGPCB Ultra-Thin Single-Sided Flex プリント基板 with Aluminum Stiffener represents the optimal fusion of flexible circuit technology and structural reinforcement. This solution is engineered to meet the critical challenge of requiring both dynamic flexibility and localized rigidity, 熱散逸の強化, and superior dimensional stability within constrained spaces.

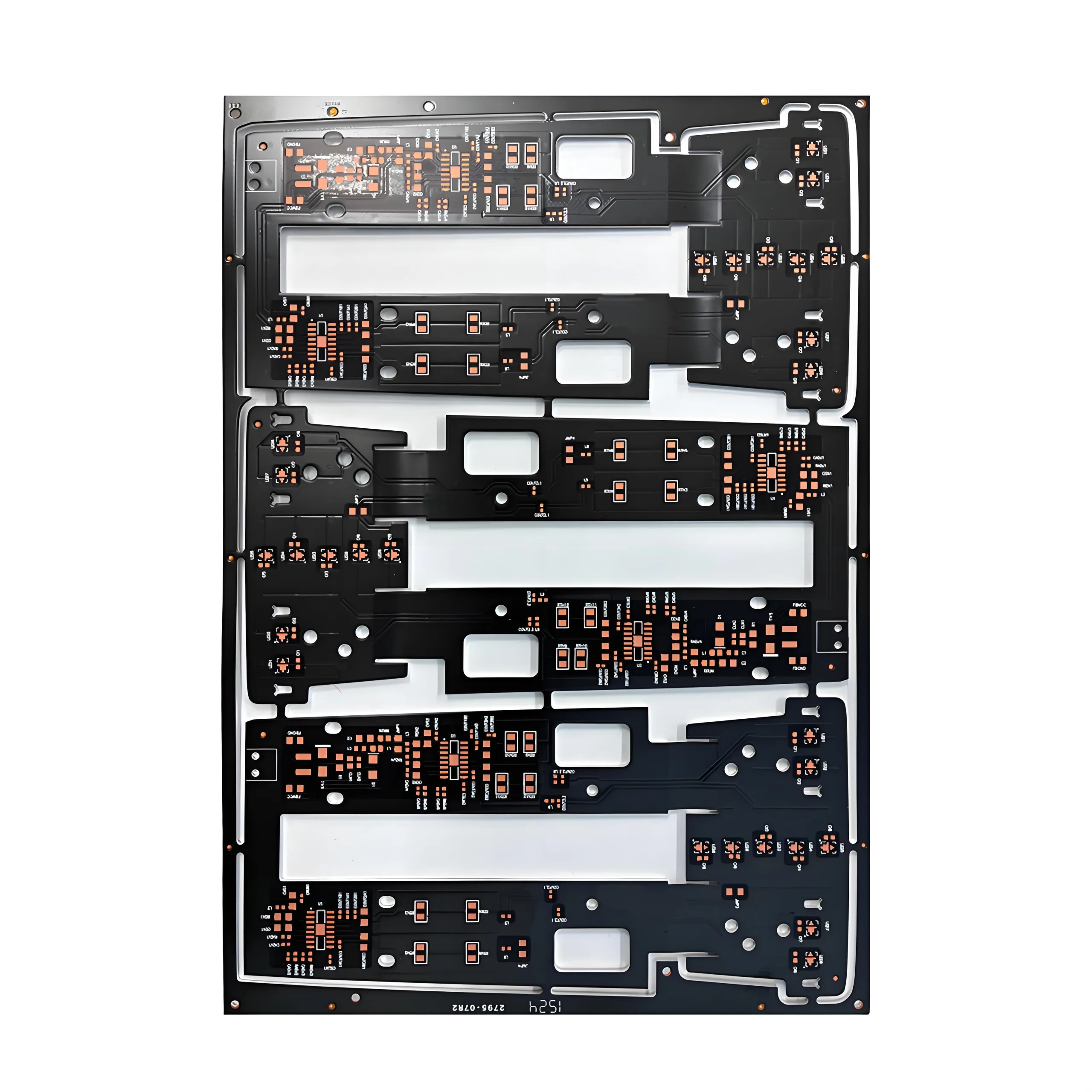

This product is scientifically classified as a: Single-Sided, Adhesive-Based Flexible Printed Circuit (FPC) with a Localized Aluminum Stiffener. It features a standard single-sided FPC construction with a precisely bonded aluminum alloy stiffener in specific zones, creating a cost-effective “rigid-flex-like” performance where it matters most.

主な仕様

-

レイヤー数: 1 層 (Single-Sided Conductor)

-

全体の厚さ: 0.2mm ±0.08mm (Including base material, 銅, and stiffener)

-

基本材料: Shengyi S1145 or equivalent 1オンス (70μm) 銅 / 25µm Polyimide (PI) Single-Sided, Adhesive-Based Flex Laminate

-

Stiffener Material: Aluminum Alloy (例えば。, 5052 または 1060)

-

表面仕上げ: OSP (有機はんだ付け性防腐剤)

-

基板寸法: 240mm x 165mm (Customizable per design)

Design Essentials & Structure Analysis

Successful aluminum stiffener FPC design begins with precise application analysis. Design engineers must define:

-

Stiffener Placement: Accurately identify areas for connector mounting, コンポーネントの配置, or mechanical fastening.

-

Dynamic Flex Zone Planning: Ensure bending occurs only in designated flexible areas, avoiding the stiffener to maximize flex life.

-

Thermal Management Path: Utilize the aluminum’s high thermal conductivity by connecting copper pads under heat-generating コンポーネント (例えば。, LED, IC) directly to the stiffener, creating an efficient heat-spreading pathway.

-

許容範囲 & Registration: Strictly control the alignment tolerance between the stiffener and the FPC to ensure accurate mounting hole placement.

それがどのように機能するか & Performance Advantages

The PCB with aluminum stiffener operates on a simple yet effective principle:

-

In Flexible Areas: The thin PI and copper construction provides excellent dynamic flexing and space-saving capabilities.

-

In Stiffened Areas: The aluminum plate offers rigid PCB-like mechanical support, preventing tearing during connector mating or screw fastening, while rapidly dissipating localized heat.

Core Features & 利点:

-

Exceptional Thinness: ~0.2mm profile ideal for ultra-slim devices.

-

Targeted Rigidity-Flexibility: Solves the “where to be rigid, where to be flexible” dilemma in a single, cost-effective package.

-

Enhanced Thermal Performance: The aluminum stiffener acts as an integrated heat spreader, improving component reliability.

-

Superior Dimensional Stability: The stiffened area resists warping under thermal and mechanical stress, ensuring precise assembly.

-

高い信頼性 & 耐久性: Protects solder joints and vias in critical areas from stress and fatigue.

-

OSP表面仕上げ: Provides excellent solderability and a flat surface for reliable SMT assembly.

製造工程 & 品質管理

UGPCB employs a mature flex circuit stiffener attachment process ensuring precision and reliability:

-

FPC Fabrication: Processing of adhesive-based laminate (例えば。, 盛義) through patterning, エッチング, and drilling.

-

表面仕上げ: Application of OSP coating to exposed copper pads.

-

精密ラミネート: Bonding of the pre-cut aluminum stiffener to the FPC using controlled heat and pressure with adhesive (pre-preg or base material adhesive layer).

-

Contour Routing & Profiling: Final board outline, stiffener shape, and mounting holes are created via CNC or laser cutting.

-

包括的なテスト: Includes electrical testing (Flying Probe/Fixture), dimensional あおい, and peel strength tests for the stiffener bond.

主要なアプリケーション & ユースケース

これ ultra-thin flex PCB with metal stiffener に最適です:

-

家電: Side-key flex cables, camera module FPCs, display connectors in smartphones/tablets.

-

LED Lighting: Ultra-thin LED strips and flexible neon signs, where the stiffener aids in heat sinking and mechanical fixing.

-

カーエレクトロニクス: Sensor wiring harnesses, dashboard backlight units requiring vibration resistance.

-

産業機器: Connections for precision probes, internal wiring in robotic arms needing localized reinforcement.

-

医療機器: Internal interconnects for portable medical equipment demanding lightweight reliability.