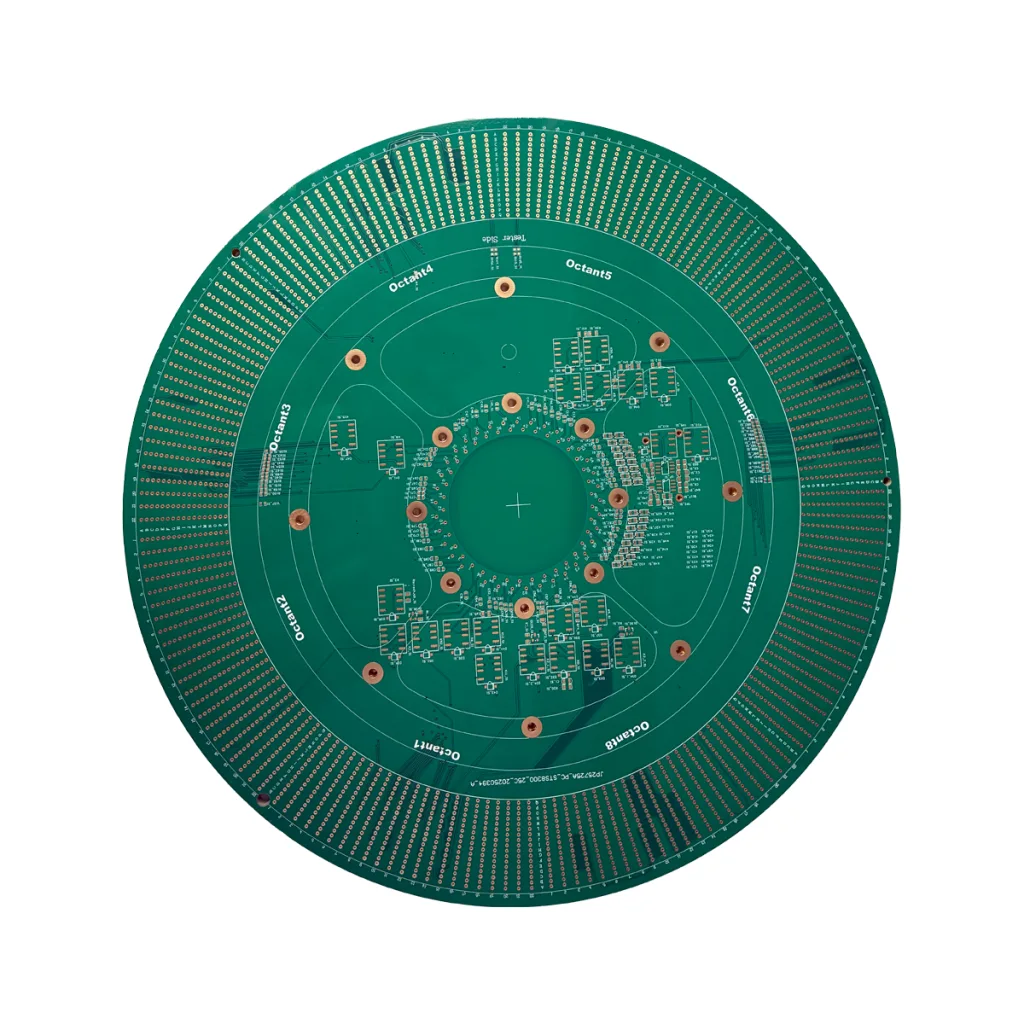

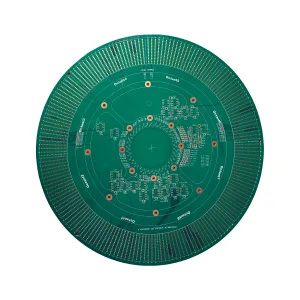

Introduction to UGPCB’s ATE Probe Card PCB

UGPCB’s 50-layer ATE (自動試験装置) Probe Card プリント基板 is a precision-engineered solution designed for high-frequency semiconductor testing. It enables accurate signal transmission between test equipment and integrated circuits (IC), ensuring reliable performance in mission-critical environments.

主要な技術仕様

-

レイヤー数: 50 レイヤー

-

厚さ: 198 ミル

-

材料: FR4 HTg (High-Temperature Glass Epoxy)

-

最小穴サイズ: 5 ミル

-

BGA の間隔: 0.35mm

- 銅の厚さ:2/2オンス

-

アスペクト比: 40:1

-

ドリルから銅までの距離: 3 ミル

-

POFV (フィルドビア上にメッキ): はい

-

表面仕上げ: ENEG (Electroless Nickel Electroless Gold)

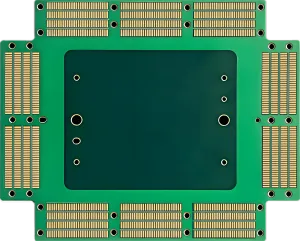

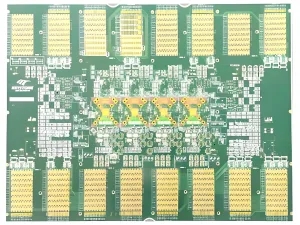

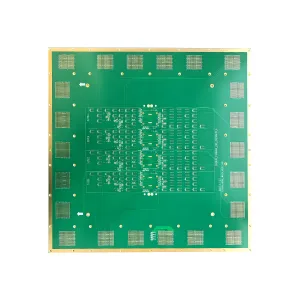

Design and Structural Innovations

Critical Design Features

-

High-Density Interconnects: The 50-layer architecture supports ultra-fine routing for BGA components with a 0.35mm pitch, essential for modern IC testing.

-

Advanced Material: FR4 HTg ensures thermal stability (Tg ≥ 180°C), preventing deformation during high-power testing cycles.

-

精密穴あけ: あ 40:1 aspect ratio and 5 mil microvias enable reliable signal paths in tightly spaced layouts.

-

POFV テクノロジー: Filled and plated vias enhance mechanical strength and thermal dissipation, critical for prolonged testing operations.

Structural Advantages

-

Ultra-Short Drill-to-Copper Distance: 3 mil spacing minimizes signal loss and crosstalk.

-

ENEG Surface Finish: Provides exceptional oxidation resistance and stable contact surfaces for probe needles.

Performance and Functional Applications

運営原則

The PCB routes electrical signals between test probes and ICs with minimal latency. The FR4 HTg substrate maintains dielectric consistency under thermal stress, while POFV ensures uninterrupted connectivity in high-vibration environments.

キーパフォーマンスメトリック

-

Thermal Endurance: Stable performance at temperatures up to 180°C.

-

信号の完全性: Controlled impedance (±8%) and low insertion loss (<0.5DB).

-

Mechanical Durability: Resists delamination during 10,000+ test cycles.

主な使用例

-

半導体検査: Validates logic chips, メモリモジュール, and processors in ATE systems.

-

Aerospace Electronics: Used in avionics testing rigs requiring ultra-reliable PCBs.

-

5G and IoT Device Production: Ensures signal accuracy in high-frequency RF component testing.

-

Automotive IC Validation: Deployed in ADAS and ECU testing workflows.

製造工程と品質保証

製造ワークフロー

-

Material Cutting: FR4 HTg laminates are precision-cut to required dimensions.

-

レーザー穴あけ加工: 達成 5 mil holes with a 40:1 aspect ratio using CO₂ lasers.

-

Plating and Via Filling: POFV technology reinforces vias with copper plating.

-

レイヤーの配置: 50-layer stackup is bonded under high pressure and temperature.

-

表面処理: ENEG coating is applied for corrosion resistance.

-

厳格なテスト: Includes electrical continuity checks, impedance testing, and thermal cycling validation.

Quality Standards

-

IPC-6012クラス 3 コンプライアンス: Guarantees reliability for harsh industrial applications.

-

100% 自動光学検査 (あおい): Detects micro-defects in high-density layouts.

Summary of Competitive Advantages

-

Ultra-High Density: Supports miniaturized IC testing with 0.35mm BGA spacing.

-

熱弾性: FR4 HTg ensures stability in extreme conditions.

-

Industry-Leading Precision: 5 mil microvias and 3 mil drill-to-copper spacing.

-

Broad Compatibility: Compatible with major ATE platforms like Teradyne and Advantest.

This PCB combines cutting-edge engineering, stringent quality controls, and specialized materials to meet the demands of next-generation semiconductor testing.

UGPCBのロゴ

UGPCBのロゴ