製品の概要

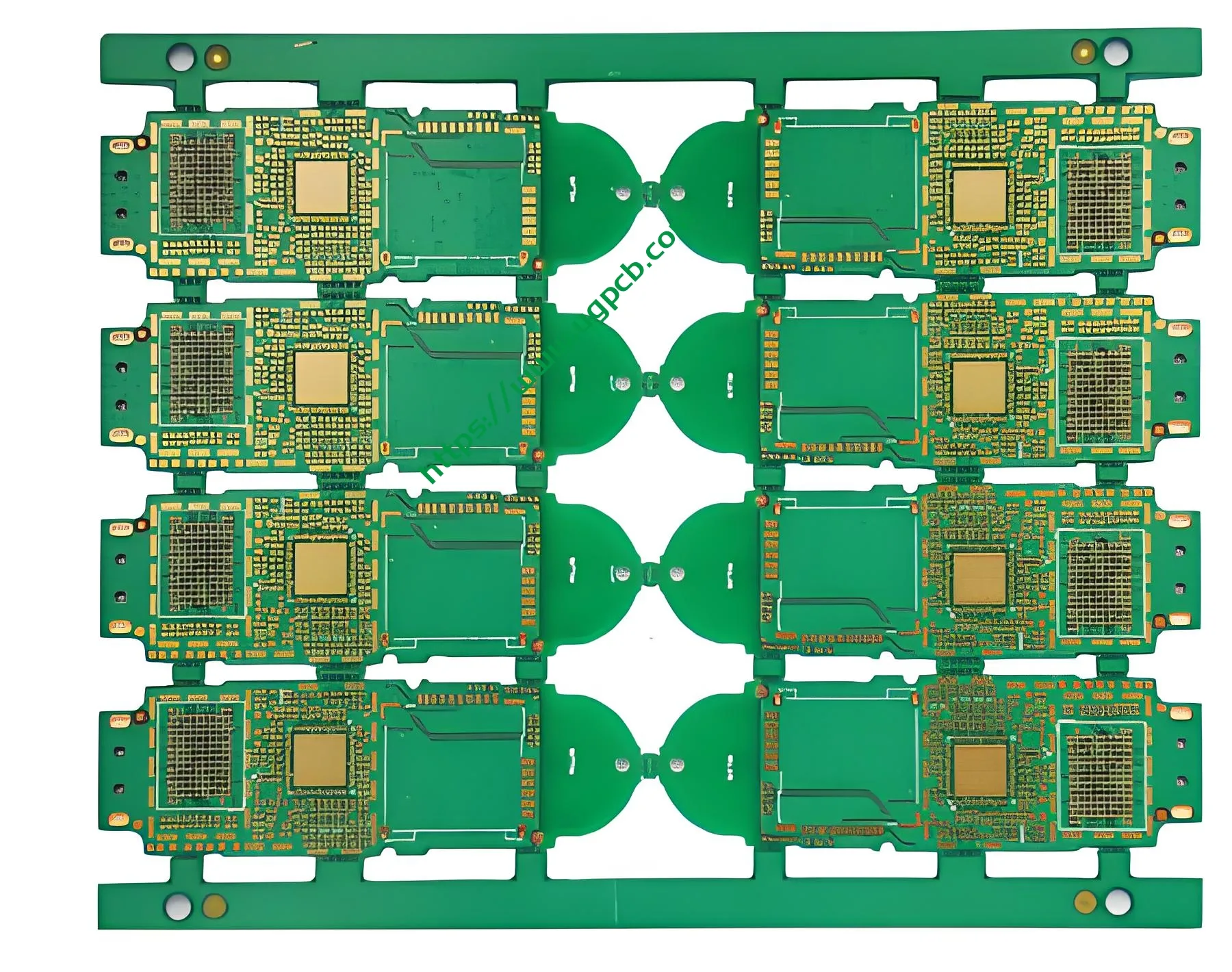

The 6L 1+N+1 HDI mobile mainboard is a high-density interconnect (HDI) プリント基板 (プリント基板) designed for use in mobile devices. With its advanced design and construction, this mainboard offers superior performance and reliability for demanding mobile applications.

意味

HDI stands for High-Density Interconnect, which refers to PCBs that have higher wiring density than traditional PCBs. The “1+N+1” designation indicates the layer structure of the PCB, with one power layer, n信号層, and one ground layer.

設計要件

The design of the 6L 1+N+1 HDI mobile mainboard must meet several key requirements:

- High signal integrity to support fast data transfer rates

- Low crosstalk and interference to ensure reliable communication

- Robust mechanical properties to withstand the stresses of daily use

- Thermal management to dissipate heat effectively

作業原則

The 6L 1+N+1 HDI mobile mainboard operates by connecting various electronic components through a network of conductive pathways. These pathways are created using copper traces on the PCB layers, which are insulated from each other by layers of dielectric material. Electrical signals travel along these traces to perform the device’s functions.

目的とアプリケーション

This type of mobile mainboard is commonly used in smartphones, 錠剤, and other portable electronic devices where space is limited but performance requirements are high. Its compact size and high functionality make it ideal for modern mobile technology.

分類

The 6L 1+N+1 HDI mobile mainboard falls under the category of high-end mobile mainboards due to its advanced features and construction. It is designed specifically for mobile applications requiring high performance and reliability.

Materials Used

The main material used for this mainboard is FR-4, a flame-resistant glass-epoxy laminate composite. This material provides excellent thermal stability and mechanical strength, making it suitable for high-performance mobile applications.

性能特性

- 高い信号の完全性: Ensures fast data transfer rates without loss or distortion.

- Low Crosstalk: Minimizes interference between adjacent signal traces.

- Robust Mechanical Properties: Withstands the physical stresses of daily use.

- Effective Thermal Management: Dissipates heat efficiently to prevent overheating.

構造と機能

- Layer Structure: Consists of six layers with a configuration of 1+N+1, where N represents the number of signal layers.

- 銅の厚さ: Inner layers have a thickness of 1 オンス (オンス), while outer layers are 0.5 オンス.

- 表面処理: イマージョンゴールド, which provides excellent solderability and corrosion resistance.

- 最小トレース/スペース: Capable of producing fine details with minimum trace widths and spaces of 3 ミル.

- Hole Types: Mechanically drilled holes as small as 0.2 mm and laser-drilled holes as fine as 0.1 mm.

製造工程

The manufacturing process for the 6L 1+N+1 HDI mobile mainboard involves several stages:

- 材料の準備: Selection of high-quality FR-4 substrates.

- レイヤースタッキング: Arranging the layers in the desired order.

- エッチング: Removing excess copper to create the desired circuit pattern.

- メッキ: Applying a thin layer of metal to the exposed copper areas.

- 表面処理: Applying immersion gold for enhanced solderability.

- 組み立て: Mounting components onto the mainboard.

- テスト: Conducting thorough electrical and functional tests to ensure quality.

- 最終検査: Visual and automated optical inspection to check for defects.

- 包装: Safely packaging the finished product for shipment.

ユースケースシナリオ

- 家電: スマートフォン, 錠剤, スマートウォッチ, 等.

- ウェアラブルデバイス: Fitness trackers, health monitors, 等.

- カーエレクトロニクス: In-car entertainment systems, navigation units, 等.

- 産業用アプリケーション: コントロールパネル, sensor interfaces, 等.

要約すれば, the 6L 1+N+1 HDI mobile mainboard is an advanced PCB designed specifically for high-performance mobile applications. Its robust construction, superior signal integrity, and efficient thermal management make it an ideal choice for modern mobile technology.