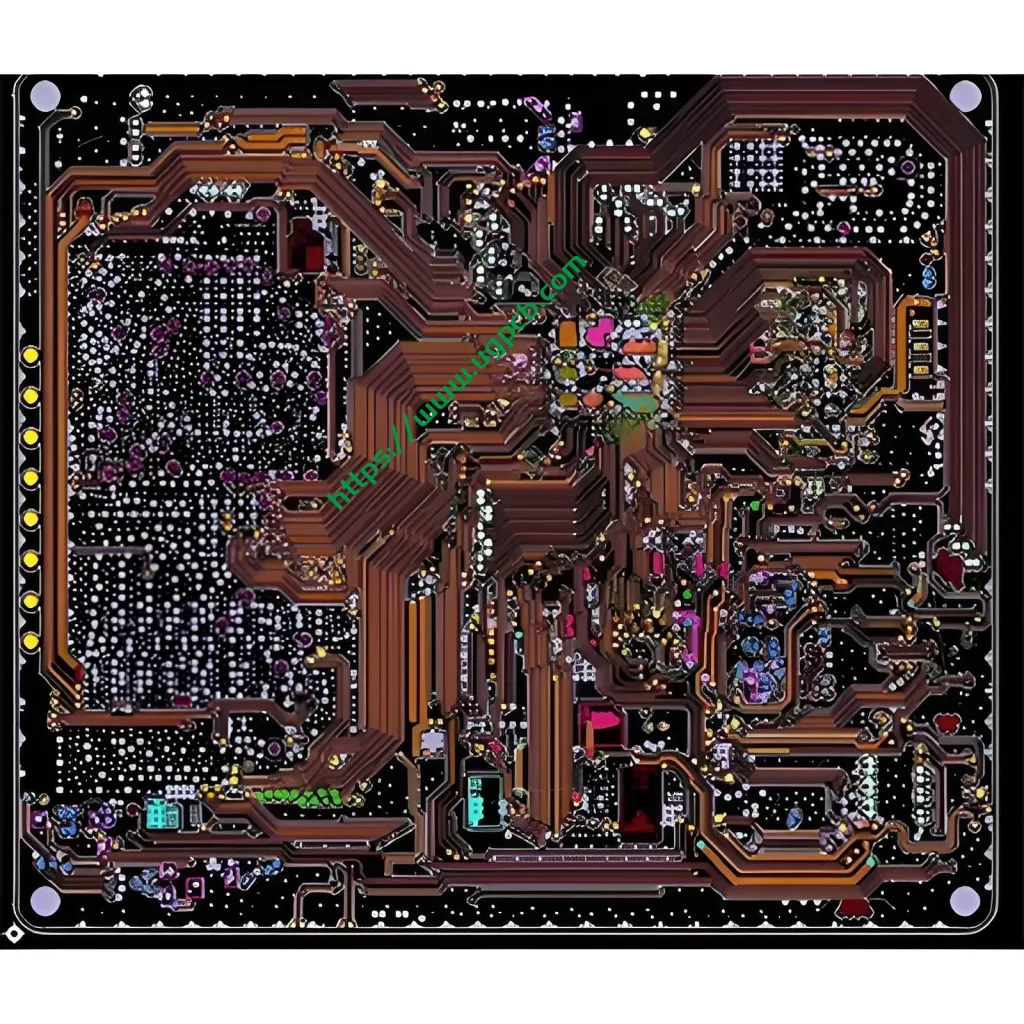

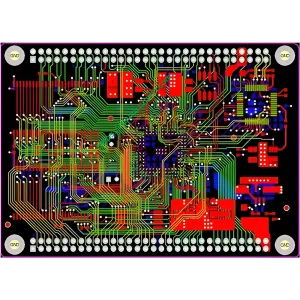

Any Layer HDI PCB: The Most Complex Design Structure

概要

Any Layer HDI PCB is the most complex HDI PCB design structure, offering unparalleled connectivity and performance.

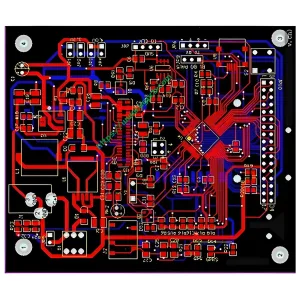

High-Density Interconnect Layers

All Layers as HDI

In this structure, all layers are high-density interconnect layers, allowing for free interconnection of conductors on any layer of the PCB.

Copper-Filled Stacked Microvia Structure

The copper-filled stacked microvia structure facilitates this interconnectivity, providing a reliable and efficient means of connecting various layers.

アプリケーション

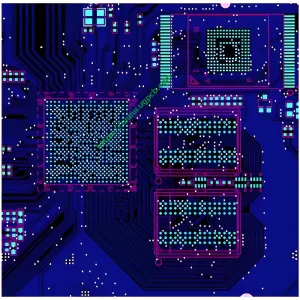

Highly Complex Devices

This structure is ideal for highly complex, high pin-count devices such as CPU and GPU chips used in handheld and mobile devices.

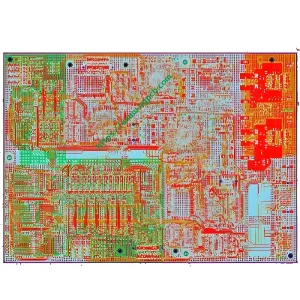

Excellent Electrical Characteristics

The design yields excellent electrical characteristics, 高性能アプリケーションに適しています.

利点

Reliable Interconnect Solution

The Any Layer HDI PCB structure provides a reliable interconnect solution for complex devices, ensuring stable and efficient performance.

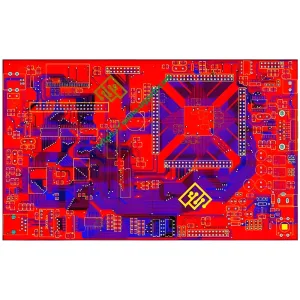

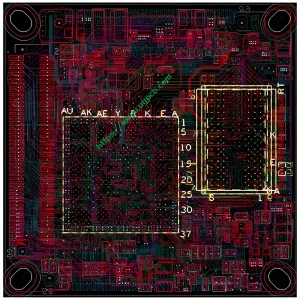

UGPCBアドバンテージ

この構造, featuring UGPCB technology, represents a significant advancement in PCB design and manufacturing.

UGPCBのロゴ

UGPCBのロゴ