高周波ハイブリッドスプリントの構造

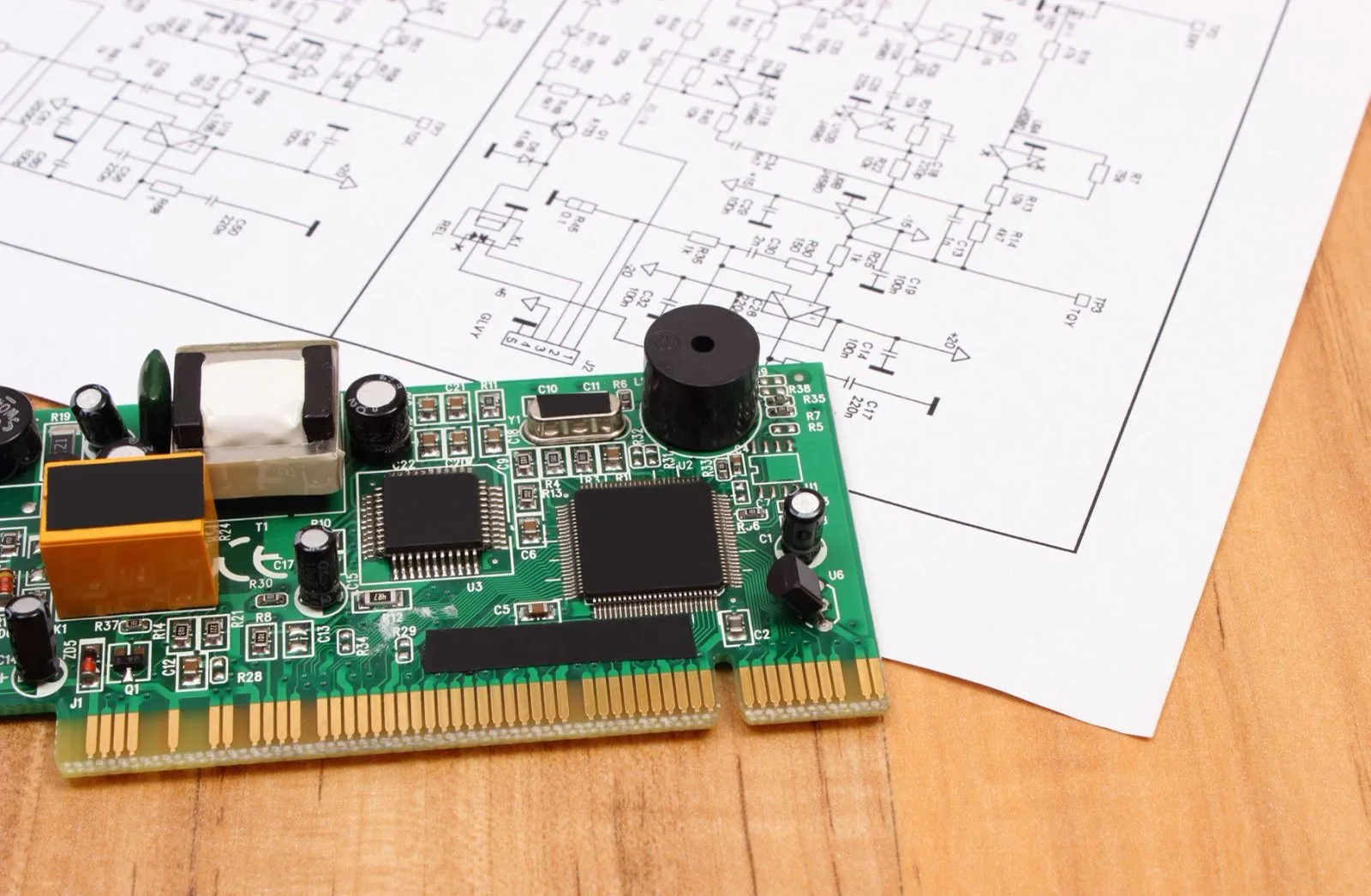

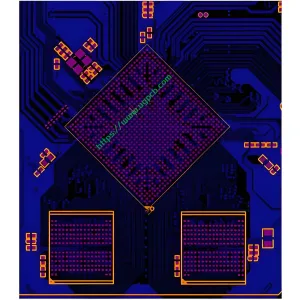

ベースプレートとレイヤー

高周波ハイブリッドスプリントには、ベースプレートが含まれています, 折り畳まれ、最初の内側のワイヤレイヤーに配置されます, 最初の外側のワイヤ層, はんだマスクインク層の上面が順番に下から上まで. はんだ抵抗インク層の2番目の層も存在します.

基質組成

基板には、高周波エリアと補助領域が含まれます. 補助領域は固定されています, そして、高周波エリアのインレイは固定位置に配置する必要があります.

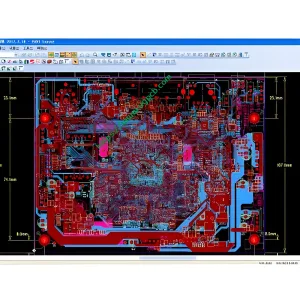

高周波ハイブリッドスプリントのユーティリティモデル

スプリントの分割

ユーティリティモデルは、2つの部分に分割された高周波ハイブリッドスプリントを提供します: 高周波エリアと補助エリア. 機械的なサポートを提供します.

高周波エリアの独立した配置

ユーティリティモデルは、高周波エリアが独立して配置されていることを明らかにしています, そして、高周波領域のみが高周波材料でできています. これにより、高周波ボード材料の使用が最小化され、生産コストが削減されながら、高周波信号を満たします。.

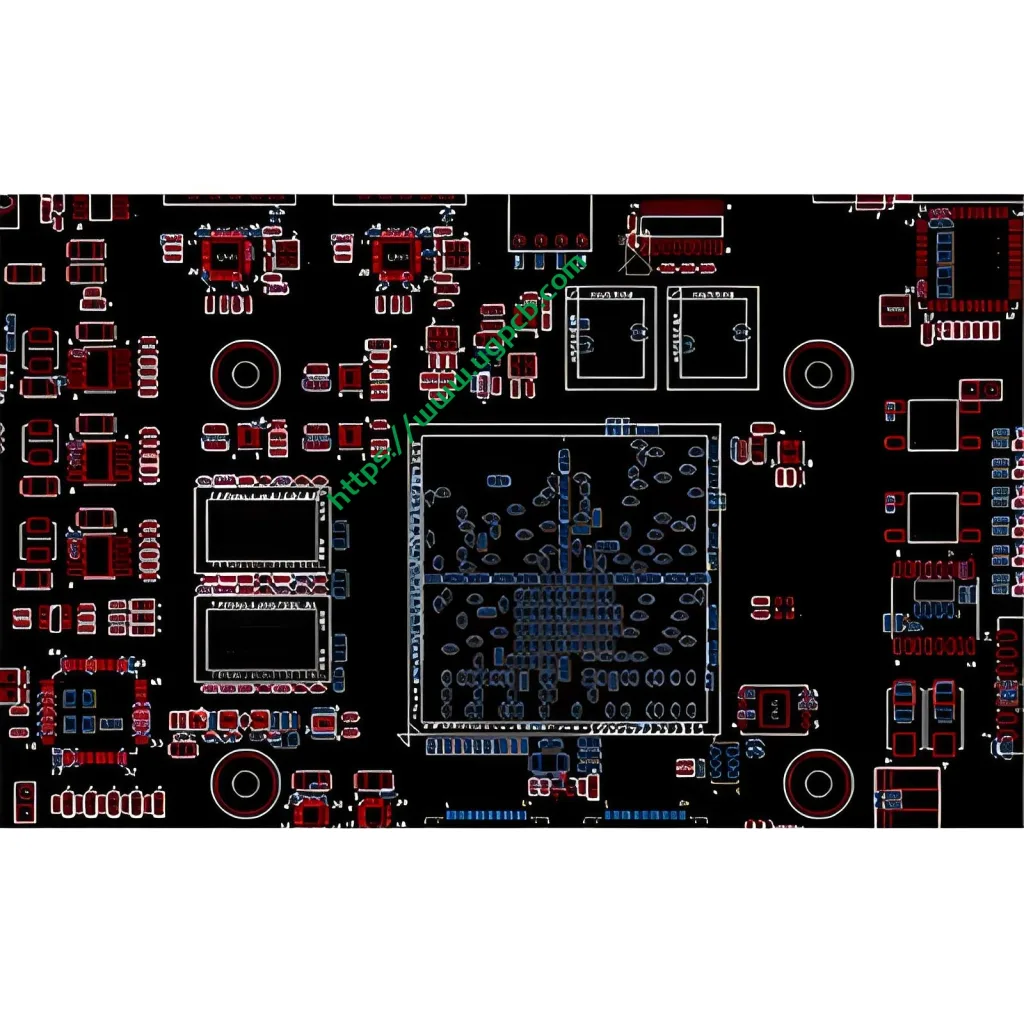

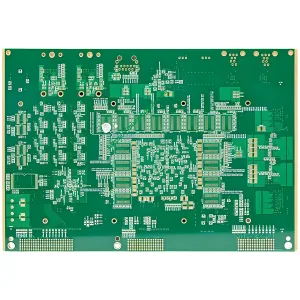

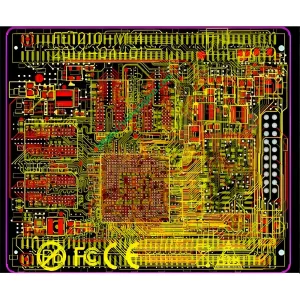

製品仕様

分類とレイヤー

- 高周波ハイブリッド製品分類レイヤー: 6 レイヤー

材料と寸法

- 使用済みボード: ロ4350b + FR4

- 厚さ: 1.6mm

- サイズ: 210mm x 280mm

表面処理と開口部

- 表面処理: 金メッキ

- 最小開口: 0.25mm

アプリケーションと機能

- 応用: コミュニケーション

- 特徴: 高周波混合圧力

UGPCBのロゴ

UGPCBのロゴ