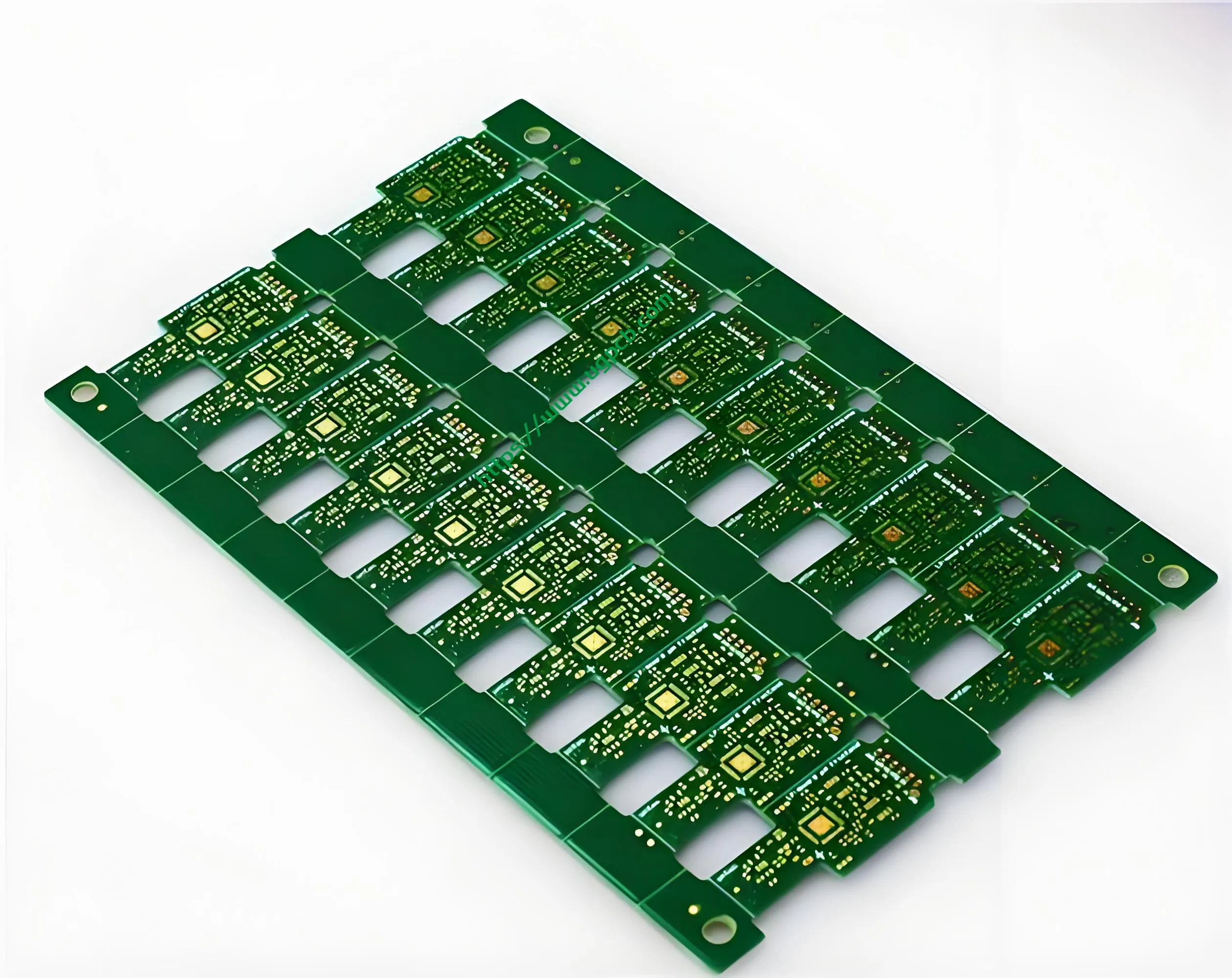

High-Density Double-Sided PCB for Consumer Electronics

|With 60-80% higher wiring density than single-sided boards, this 1.6mm double-sided PCB enables more compact and reliable electronic designs.

両面 プリント基板 (プリント基板) feature conductive copper layers on both top and bottom sides of an insulating substrate, interconnected by metallized vias. This fundamental architecture is critical for modern, space-constrained electronic devices.

UGPCB’s double-sided PCB utilizes premium KB-6160C FR-4 epoxy glass substrate paired with 1.5OZ finished copper thickness そして イマージョンゴールド (同意する) 表面仕上げ. This combination delivers a robust interconnect solution ideal for consumer electronics, 産業用制御, and telecommunications applications where reliability, パフォーマンス, and efficient use of space are paramount.

01 Product Definition & コアの利点

A double-sided printed circuit board is a foundational component in modern electronics, providing conductive pathways on both sides of an insulating core.

Electrical connection between the two layers is achieved through metallized through-holes or vias. This design overcomes the spatial limitations inherent to single-sided boards.

For consumer electronics, the flexibility of double-sided PCBs allows for cross-routing and copper pour patterns, which can reduce material costs by 30-50% compared to more complex multi-layer solutions while offering superior design freedom.

The primary structural advantages over single-sided PCBs are dual-sided routing capability そして reliable via-based interlayer conduction. This structure efficiently solves routing congestion issues and supports more complex circuit requirements.

02 材料仕様: KB-6160C FR-4 Substrate

UGPCB employs KB-6160C FR-4, an epoxy glass cloth copper-clad laminate (CCL) with ultraviolet (UV) blocking functionality.

This substrate is particularly suitable for PCBs requiring simultaneous double-side solder mask curing そして 自動光学検査 (あおい).

Key properties of KB-6160C FR-4 include:

-

Excellent Thermal Resistance: 高いガラス転移温度 (TG) for reliable performance during soldering and operation.

-

優れた機械的強度: Enhanced rigidity and dimensional stability compared to standard FR-4 materials.

-

Environmental Compliance: ハロゲンフリー, アンチモニーフリー, and red phosphorus-free formulation, meeting stringent environmental safety standards (例えば。, RoHS).

03 動作原理 & 構造設計

The core operational principle of a double-sided PCB is electrical interconnection through metallized vias.

Conductive patterns on both sides of the board are linked via these plated holes, enabling current flow and signal transmission across layers.

The standard stack-up for UGPCB’s 1.6mm double-sided board is as follows:

-

最上層: 銅箔 (1.5OZ finished thickness)

-

はんだマスク: Green or White (optional)

-

Insulating Core: KB-6160C FR-4 Epoxy Glass Substrate

-

下層: 銅箔 (1.5OZ finished thickness)

-

表面仕上げ: イマージョンゴールド (同意する) over Nickel

Via metallization is achieved through a desmear and electrodes copper plating process, typically using either thin-copper electroless deposition with subsequent electrolytic plating or direct metallization transfer for thicker deposits.

04 Precision Manufacturing Process Flow

The manufacturing of double-sided PCBs is more complex than single-sided types, primarily due to the requirements for dual-layer patterning そして reliable via formation. UGPCB’s advanced process flow ensures high quality and consistency.

The Pattern Plating Process is the industry-standard method. The detailed sequence is: Cutting → Drilling → Desmear & Electroless Copper Deposition → Dry Film Lamination & Imaging → Pattern Electroplting → Etching → Solder Mask Application → Legend Printing → Surface Finish (同意する) → Profiling/Routing → Electrical Testing → Final Inspection & 包装.

Electroless Copper Deposition is the critical step for initial via metallization. UGPCB employs a controlled chemical process to deposit a thin, uniform copper layer on the drilled hole walls, which is then electroplated to the specified thickness.

For high-reliability applications, we offer the Solder Mask Over Bare Copper (SMOBC) プロセス. This method enhances solderability, prevents solder bridging on fine-pitch features, and improves shelf life.

05 表面仕上げ & Key Performance Characteristics

UGPCB specifies イマージョンゴールド (同意する) as the standard surface finish. This provides:

-

Excellent Surface Planarity: Crucial for fine-pitch component soldering.

-

Superior Solderability & Wettability: 信頼性の高いはんだ接合を保証.

-

Low Contact Resistance: Ideal for connectors and gold-finger edges.

-

Long Shelf Life: Resists oxidation better than bare copper or silver finishes.

The 1.5OZ Finished Copper Thickness ensures enhanced current-carrying capacity and improved thermal management compared to standard 1OZ copper. This is vital for power paths and heat dissipation in compact designs.

Technical Advantages Summary:

-

費用対効果: Optimal balance between performance and cost for mid-complexity circuits.

-

設計の柔軟性: Enables more efficient component placement and routing.

-

熱性能: Dual-sided copper aids in heat spreading.

06 Diverse Application Scenarios

両面PCB, with their balanced performance and cost, are deployed across numerous industries:

家電: Used extensively in smartphones, 錠剤, ラップトップ, テレビ, and audio equipment for mixed-signal (RF/digital) レイアウト.

産業用自動化: Found in control systems, measurement instruments, 電源, and motor drives due to their reliability and increased current capacity.

通信: Employed in networking equipment, ルーター, and base station modules where routing density is key.

Computer Peripherals: Common in printers, scanners, and external storage devices.

07 品質保証 & Technical Compliance

UGPCB implements a rigorous quality management system to ensure every PCB meets exacting standards.

Advanced Manufacturing Equipment: We utilize systems like the LDI for high-precision, double-side simultaneous imaging, achieving registration accuracy within ±12.5μm, which significantly improves production yield.

Specialized Testing: For high-frequency or high-speed designs, we perform additional 信号の完全性 (そして) そして インピーダンス制御 テスト. Drilling parameters and cleaning processes are strictly controlled to prevent defects like hole voids or insufficient copper.

環境 & Process Leadership: Our processes adhere to the latest environmental standards. We employ advanced technologies like carbon direct metallization そして conductive polymer deposition as modern, efficient alternatives to traditional chemical copper processes, aligning with IPC-6012 そして IPC-A-600 acceptability standards.

A circuit designer finalizes the layout, confident that the 1.5OZ copper and robust vias will handle the device’s power needs. Each plated via acts as a microscopic bridge, seamlessly connecting the top and bottom layers, transforming intricate schematics into a stable, functioning electronic system.

As electronics continue their trend toward miniaturization and higher performance, PCB technology is advancing toward trace widths of 25μm (1 ミル) and densities approaching 75% of a four-layer board’s capacity. For engineers facing the dual challenges of space constraints and performance requirements today, the solution may well reside within the layers of this reliable 1.6mm double-sided PCB from UGPCB.