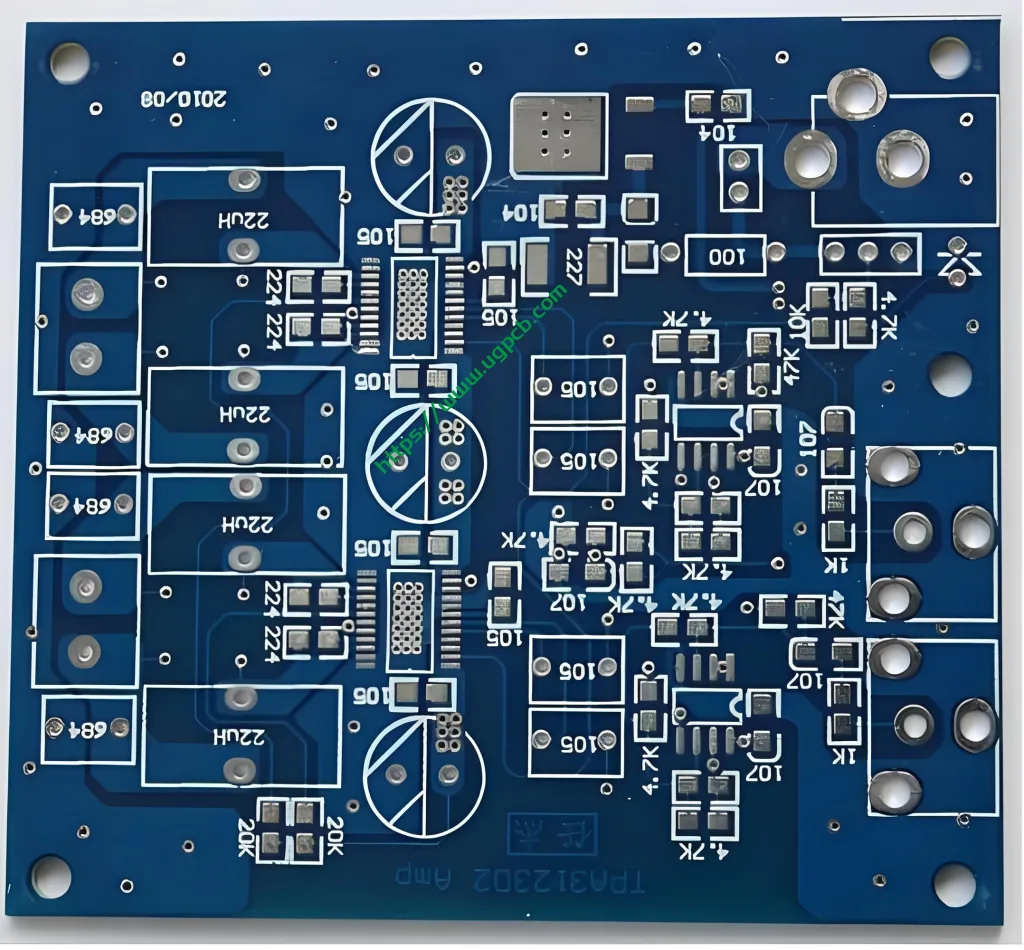

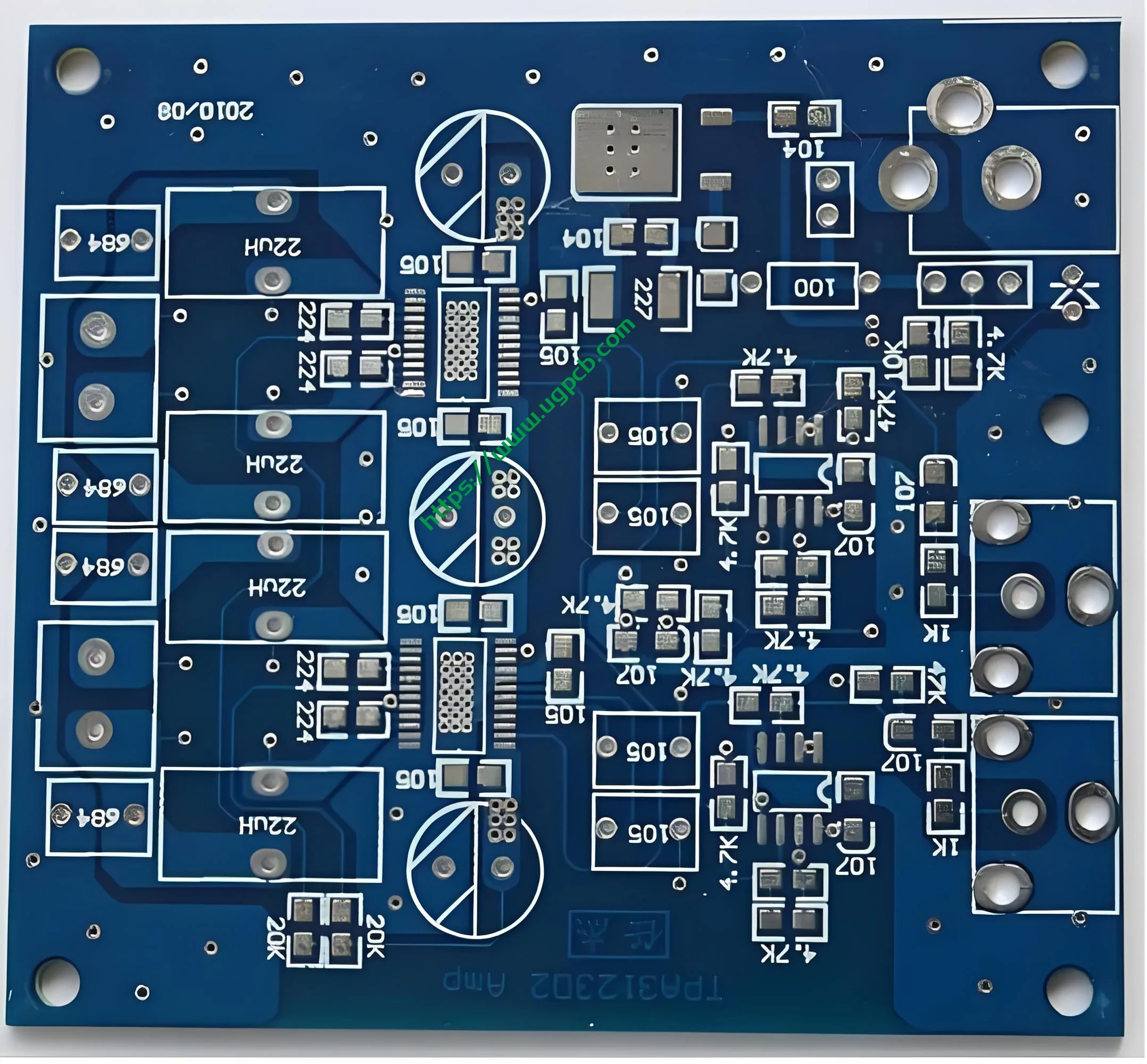

Introduction to UGPCB’s Double-Sided PCB for Relay Protection

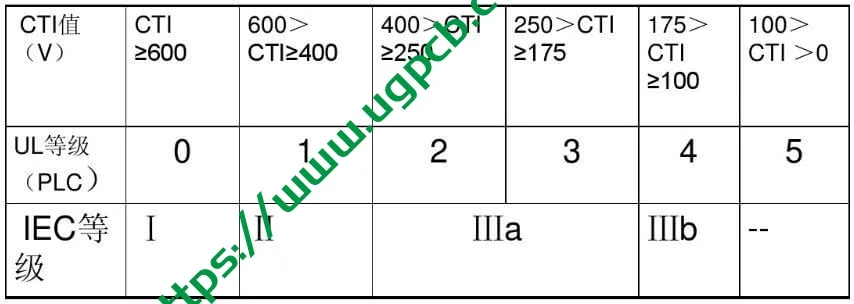

UGPCB specializes in manufacturing high-performance 両面 プリント基板 (プリント基板) tailored for relay protection systems. These PCBs are engineered with FR-4 epoxy glass cloth as the 基本材料, ensuring excellent electrical insulation and mechanical durability. Featuring a finished thickness of 1.6mm and a 1oz copper thickness (approximately 35μm), these boards support robust current-carrying capacity. The OSP (有機はんだ付け性防腐剤) 表面処理 enhances solderability while protecting the copper pads from oxidation. With a minimum trace and spacing of 8mil (0.2mm), UGPCB’s designs achieve optimal signal integrity for precision-driven relay protection applications. Available in both black and white solder mask colors, these PCBs comply with CTI600 standards, offering high comparative tracking index performance to prevent electrical failures in humid conditions.

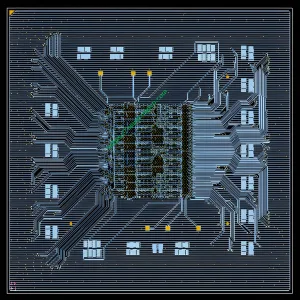

What Is a Double-Sided PCB?

あ 両面PCB incorporates conductive copper layers on both sides of an insulating substrate, のような FR-4. The layers are interconnected using plated through-holes (pths) またはVIAS, enabling complex circuitry in a compact form. Unlike single-sided PCBs, double-sided variants allow for higher component density and layout flexibility, making them ideal for intermediate-complexity devices like relay protection systems. These boards support double-sided assembly, including through-hole and surface-mount technologies (SMT), and are widely used in industrial, 通信, および自動車エレクトロニクス.

Design Guidelines for Relay Protection PCBs

-

トレース幅と間隔: UGPCB recommends a minimum of 8ミル (0.2mm) for trace width and spacing to mitigate short-circuit risks and ensure signal clarity in high-voltage environments .

-

サーマルリリーフパッド: Use cross-hatched thermal pads for large copper areas to dissipate heat during soldering, reducing the risk of virtual joints .

-

Via Specifications: For reliable interlayer connections, specify PTHs with a minimum finished hole diameter of 0.3mm and an annular ring of 0.7mm or larger .

-

Gridded Copper Planes: Implement gridded ground planes with a spacing ≥10mil to minimize PCB warping during wave soldering .

-

Solder Mask Details: Define solder mask openings precisely using the solder mask layer in design files to prevent bridging and expose thermal pads .

How Double-Sided PCBs Work in Relay Protection

In relay protection systems, double-sided PCBs function as the 中枢神経系, monitoring electrical parameters and triggering disconnection during faults. The dual-layer layout facilitates the integration of current sensors, microprocessors, および通信モジュール. 例えば, traces on the top layer may carry low-voltage control signals, while the bottom layer handles high-current paths. メッキスルーホール create low-impedance connections between layers, ensuring rapid fault detection and response. The CTI600-rated substrate resists conductive anode filament (CAF) formation, which is critical for longevity in high-humidity settings.

Applications of UGPCB’s Relay Protection PCBs

UGPCB’s double-sided PCBs are deployed in:

-

Power Grid Relay Systems: For overcurrent and earth fault protection.

-

Industrial Control Panels: Monitoring machinery in manufacturing plants.

-

Renewable Energy Inverters: Safeguarding solar/wind power converters.

-

通信インフラストラクチャ: Protecting base station power supplies.

-

Railway Signaling Systems: Ensuring fail-safe track switching.

Classification of Double-Sided PCBs

-

素材によって: FR-4 (標準), CEM-3 (mid-range), and polyimide (高温).

-

表面仕上げによる: OSP (UGPCB’s default), 出血, 同意する, and immersion tin.

-

By CTI Rating: CTI600 (like UGPCB’s boards), CTI400, and CTI600+ for harsh environments.

Materials and Construction

-

基本材料: FR-4 glass epoxy is used for its flame-retardant properties (UL94V-0) and dielectric strength .

-

銅箔: Electrolytic copper with 1oz thickness (35μm) per side .

-

はんだマスク: Available in black or white, based on Taiyo PSR-4000 series, providing ≥10μm insulation thickness .

-

表面仕上げ: OSP forms a protective organic layer on copper pads, ensuring solderability without lead .

キーパフォーマンスメトリック

-

Dielectric Strength: Withstands high voltages between conductive layers.

-

Thermal Endurance: ガラス遷移温度 (TG) of 130–145°C prevents deformation under load .

-

CTI評価: CTI600 guarantees resistance to tracking up to 600V.

-

Warpage Tolerance: Maximum warpage of 0.7% for SMT-assembled boards .

-

Plated Through-Hole Reliability: Copper plating ≥20μm in holes ensures uninterrupted interlayer connections .

Structure of a Double-Sided PCB

UGPCB’s PCBs feature:

-

Top and Bottom Copper Layers: 35μm thick, etched into circuit patterns.

-

FR-4 Core: A 1.6mm thick insulating substrate.

-

Plated Through-Holes: Metallized with copper for layer interconnection.

-

はんだマスク層: Applied over copper, excluding solderable pads.

-

Silkscreen Legend: White or black markings for component placement.

Advantages of UGPCB’s Design

-

費用対効果: Reduces material expenses by 30–50% compared to multilayer alternatives.

-

Enhanced Design Flexibility: Supports cross-routing and optimized grounding schemes.

-

改善された熱管理: Gridded copper planes and thermal vias dissipate heat efficiently.

-

高い信頼性: CTI600 and OSP finish extend service life in demanding conditions.

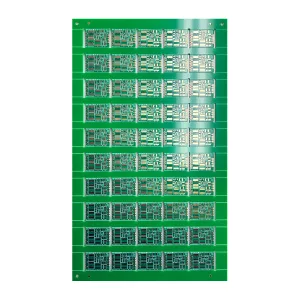

Manufacturing Process Overview

-

材料の準備: Cut FR-4 substrate to 510x610mm panels.

-

掘削: CNC drills create holes as small as 0.2mm for PTHs .

-

Electroless Copper Deposition: Catalytic oxidation builds a conductive layer in holes .

-

Pattern Imaging: Photolithography transfers circuit layouts using UV exposure.

-

Electroplating: Copper deposition thickens traces and hole walls to ≥20μm .

-

エッチング: Removes unwanted copper, defining traces.

-

ソルダーマスクの塗布: UV-curable ink printed and developed.

-

OSP Coating: Organic preservative applied to exposed copper.

-

シルクスクリーン印刷: Component indicators added.

-

Routing and V-Scoring: Panels separated into individual boards.

Common Usage Scenarios

-

Utility Substations: Housing protection relays for transformers and feeders.

-

Industrial Motor Drives: Embedding control logic for overload prevention.

-

途切れやすい電源 (UPS): Managing battery charge/discharge cycles.

-

Smart Meters: Enabling real-time energy monitoring.

結論

UGPCB’s double-sided PCB boards for relay protection combine 先端材料, precision engineering, and rigorous testing to deliver unmatched reliability. With features like FR-4 insulation, OSP coating, and CTI600 compliance, they are the optimal choice for critical power systems. Engineers seeking to enhance equipment safety and longevity can leverage UGPCB’s expertise for their next project.

UGPCBのロゴ

UGPCBのロゴ