コンピューティングの未来に力を与える: UGPCB の高性能サーバー PCB ソリューション

今日の急速に進化するデータセンターの状況において, 人工知能, とクラウドコンピューティング, サーバーのパフォーマンスと安定性はデジタル効率にとって極めて重要です. 基本的なハードウェア基盤として, サーバーの品質 プリント基板 (プリント基板) 最も重要です. 深い技術的専門知識を活用する, UGPCB はプロフェッショナルを提供します, カスタマイズされた, 高性能サーバー PCB の製造と プリント基板 (印刷回路基板アセンブリ) ワンストップソリューション.

1. 製品の概要 & 意味

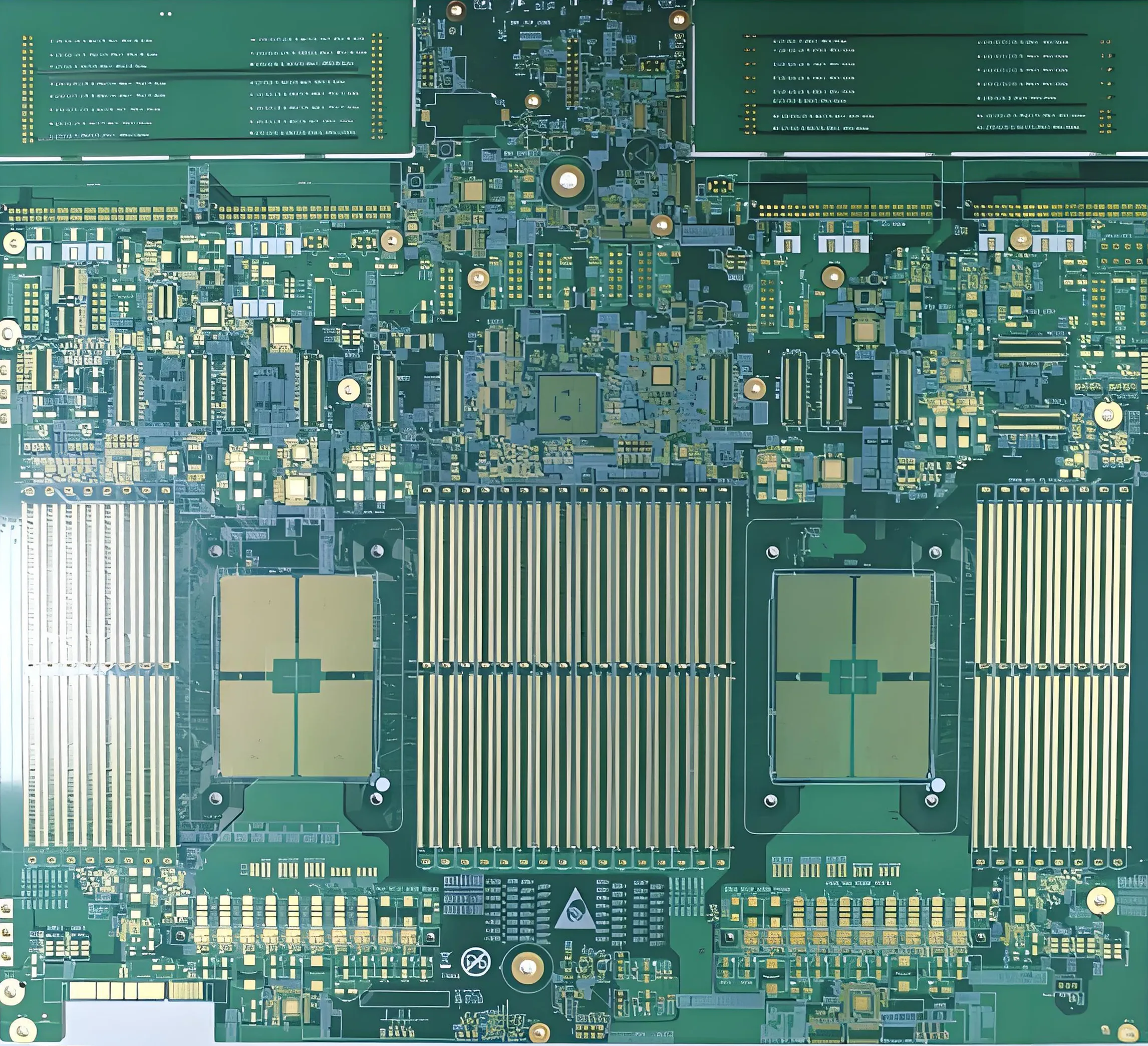

サーバー PCB は複雑です, 多層回路基板 サーバークラスの製品向けに特別に設計. その重要な使命は、CPU などのコア コンポーネントをホストすることです。, メモリ, 高速バス, 数十Gbps以上の速度での安定した信号伝送を確保しながら、パワーモジュールとの接続を実現します。. これは単なる物理的な接続プラットフォームではなく、システムの信号の完全性を保証するコア要素です, パワーの完全性, 熱性能と.

あなたが提供する仕様 (板厚: 2.8mm±10%, 22 レイヤー, 2/1 オンスの銅の重量, 0.1/0.1 mm トレース/スペース) 典型的な高層数を定義する, 高密度, 高速サーバーPCB. ミッドエンドからハイエンドのデュアルプロセッサまたは AI サーバーマザーボードの重要なアプリケーションに適しています。, アクセラレータカード, とバックプレーン.

2. デザインの基本 & キーテクノロジー

このような先進的な製品の成功は、 PCBデザイン さまざまな最先端テクノロジーを習得するかどうかにかかっています:

-

積み重ね & インピーダンス制御: 複雑な 22 層の積層には、正確な計算を必要とします。 インピーダンス制御 (通常 50Ω シングルエンド, 100Ω差動), ~の礎を形成する 高速PCB設計.

-

バックドリリング: この重要なプロセスは、高速信号ビアから未使用の銅スタブを削除します。 (例えば。, PCIe用, DDRバス), 信号の反射と減衰を大幅に低減, シグナルインテグリティを強化する上で中心的役割を果たします.

-

高速ラミネート塗布: IT-968Gなどの高級高速素材を採用 & アイテックのIT-180A. 低い損失係数 (Df) 安定した誘電率 (DK) 信号の純度と低遅延を確保. 高いガラス転移温度 (TG >170℃) サーバーの長期にわたる高温動作下での材料の信頼性を保証します.

-

RTF (裏面処理箔) 銅: Its smoother surface profile effectively reduces “skin effect” losses for high-frequency signals on the conductor surface, 高速性能をさらに向上.

-

任意のレイヤーの HDI & ハイブリッド構造: 高密度配線をサポート. ハイブリッド建設技術との組み合わせ, 局所的な領域でさまざまな性能の材料を使用できるようになります。 (例えば。, 大電流パワーゾーン vs. 高速信号ゾーン) 特定の回路要件を満たすため.

3. パフォーマンス & 構造的特徴

-

優れた電気的性能: 極めて低い信号損失と優れたインピーダンス一貫性により、PCIe などの高速プロトコルの要求を満たします。 4.0/5.0 およびDDR4/DDR5.

-

超高信頼性: 同意する (エレクトロレスニッケルイマージョンゴールド) 表面仕上げにより平坦なはんだ付け面と優れた耐酸化性を実現, 長期的な接続信頼性の確保. 10オンスの厚さの内部銅コア (2/1ozデザインとの組み合わせ) 電力層に堅牢な通電容量と熱経路を提供します.

-

精密な製造能力: The 0.1/0.1 mm のトレース/スペースと 0.25mm の最小仕上げ穴直径は、UGPCB の高精度におけるトップレベルの専門知識を示しています。 PCB製造.

-

堅牢な熱管理: 2.8mm厚の基板構造, 厚い銅のデザインと組み合わせて, 優れた熱放散を実現, システム全体の冷却を助ける.

4. 製造工程 & 品質管理

UGPCBのサーバー プリント基板の製造 厳格に従います, 自動車エレクトロニクスグレードの品質管理プロトコル: 材料検査 → 内層イメージング → 精密ラミネート → レーザー/機械ドリリング → バックドリリング → 銅蒸着 & メッキ → 外層イメージング → ソルダーマスク → 表面仕上げ (同意する) → 電気試験 (フライングプローブ/専用治具) → 最終検査. 各ステージは高速信号テストによってサポートされます, あおい (自動光学検査), もっと, 納品されたすべての PCB が設計仕様を満たしていることを保証する.

5. アプリケーションシナリオ & 技術分類

この高性能サーバー PCB は、さまざまな用途で広く使用されています。:

-

AIサーバー & GPU アクセラレータ カード: 大規模な並列コンピューティング タスクの処理用.

-

クラウド コンピューティング データセンター サーバー: コアコンピューティングノードとして.

-

ハイエンドストレージサーバー: 高速データ保存と交換用.

-

ネットワークスイッチング装置: コアルーティングおよびスイッチングマザーボード.

科学的分類:

-

レイヤーカウントごとに: 高多層基板 (22 レイヤー)

-

テクノロジーによって: 高速・高周波基板, バックドリルPCB, 重い銅の PCB, 高密度相互接続 (HDI) プリント基板

-

アプリケーションによって: データセンター/サーバー専用PCB