Model Overview

The LED Ceramic PCB and Ceramic Substrate PCB are advanced 電子コンポーネント designed for high-performance applications. これら プリント基板 feature a robust construction and superior thermal management capabilities, making them ideal for various demanding applications.

材料構成

The core of these PCBs is composed of a ceramic 基板, which offers exceptional thermal conductivity and mechanical stability. The ceramic material used is primarily aluminum nitride (AlN), known for its high thermal conductivity and low electrical conductivity, making it an excellent choice for high-power electronics.

レイヤー構成

These PCBs are constructed as 2-layer ceramic PCBs, which means they have two layers of circuitry embedded within the ceramic substrate. This configuration allows for more complex circuit designs while maintaining the benefits of ceramic’s thermal properties.

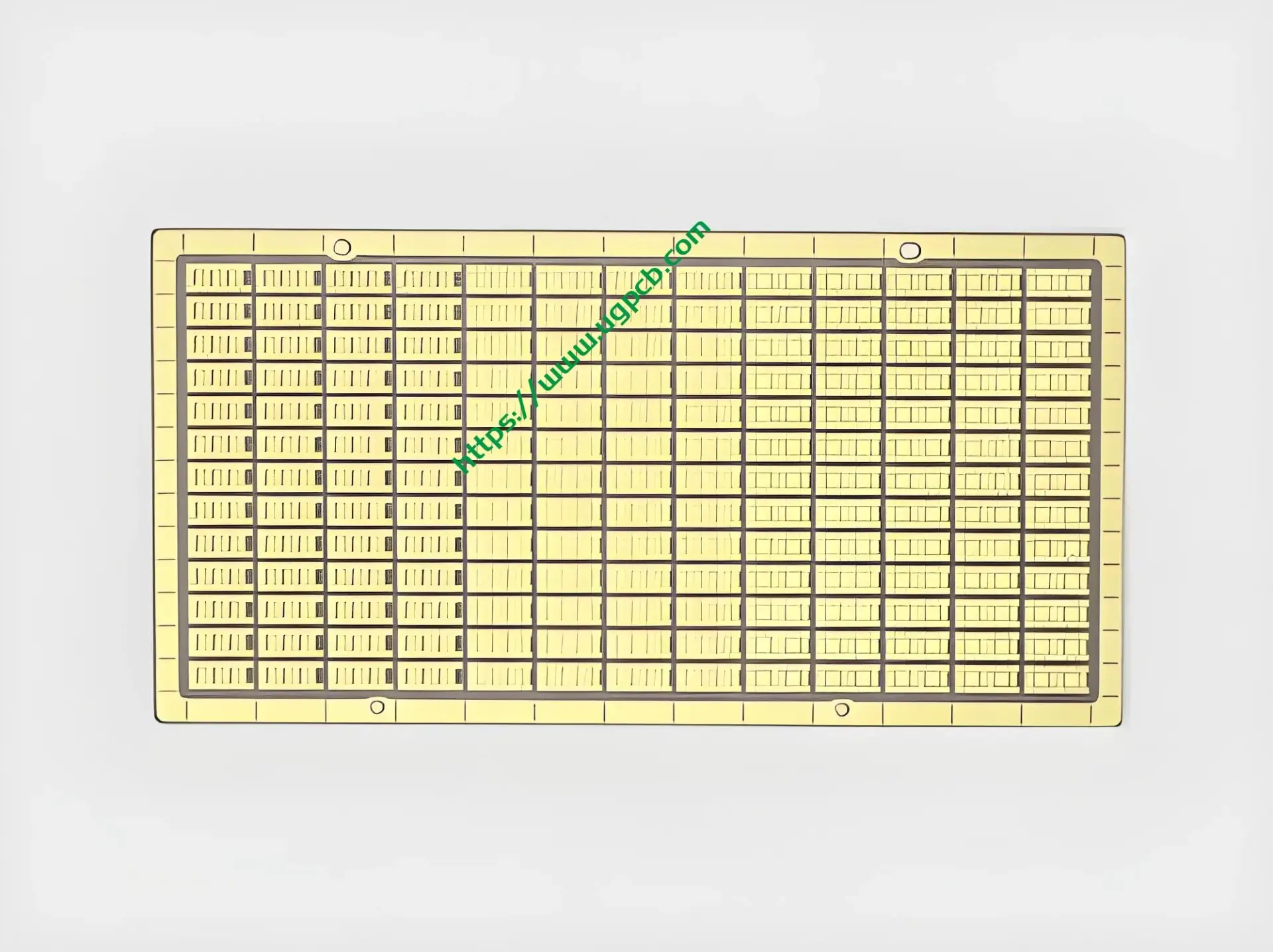

Color and Appearance

The color of the LED Ceramic PCB and Ceramic Substrate PCB is white, giving them a sleek and professional appearance. The white ceramic surface also aids in reflecting light, which can be beneficial in certain applications.

Thickness Specifications

The thickness of the aluminum nitride ceramic substrate is precisely controlled at 0.635mm, ensuring consistent performance and reliability. This thickness provides a good balance between mechanical strength and thermal conductivity.

銅の厚さ

The copper thickness on these PCBs is 1OZ (351つ), which is sufficient for carrying high currents while maintaining good electrical conductivity. The copper layer is etched to form the desired circuit patterns.

表面処理

The surface of the copper circuitry is treated with immersion gold, which provides excellent corrosion resistance and electrical conductivity. The gold thickness is >=3U”, ensuring reliable connections and long-term durability.

最小開口

The minimum aperture size on these PCBs is 0.8mm, allowing for the use of small components and tight packaging layouts. This feature is crucial for high-density electronics applications.

性能特性

The LED Ceramic PCB and Ceramic Substrate PCB offer several performance characteristics that make them superior to traditional PCBs:

- High thermal conductivity: The ceramic substrate effectively dissipates heat, preventing thermal buildup and component failure.

- 優れた電気性能: The combination of ceramic and copper provides stable electrical properties, making these PCBs ideal for high-frequency and high-power applications.

- 機械的安定性: The ceramic substrate is highly resistant to mechanical stress and vibration, ensuring reliable performance in harsh environments.

製造工程

The production of LED Ceramic PCBs and Ceramic Substrate PCBs involves several steps:

- Preparation of Ceramic Substrate: The ceramic material is processed to form the desired substrate shape and thickness.

- Circuit Design and Etching: The circuit patterns are designed and etched onto the copper layer using photolithography and etching techniques.

- Assembly and Lamination: The etched copper layers are assembled with the ceramic substrate, and the assembly is laminated to form a cohesive structure.

- 穴あけ加工とメッキ加工: Holes are drilled for component placement, and the surfaces are plated with immersion gold to provide corrosion resistance and electrical conductivity.

- 最終検査とテスト: The finished PCBs are inspected for quality and tested to ensure they meet performance specifications.

アプリケーションシナリオ

The LED Ceramic PCB and Ceramic Substrate PCB are ideal for a wide range of high-power applications, 含む:

- High-power LED lighting: These PCBs can handle the high currents and temperatures generated by high-power LEDs, making them suitable for LED lighting applications such as street lights, industrial lighting, and automotive headlights.

- Solar energy inverters: The high thermal conductivity of ceramic PCBs allows them to effectively dissipate heat generated by solar inverters, ensuring reliable and efficient operation.

- Other high-power electronics: These PCBs are also suitable for other high-power electronics applications, 電源など, motor controllers, and battery management systems.

結論は, the LED Ceramic PCB and Ceramic Substrate PCB offer exceptional performance and reliability, making them ideal for high-power and high-performance electronics applications.