組立ミスの削減

正確な設計と自動生産

フレキシブルプリント基板には多くの利点があります, 含む:

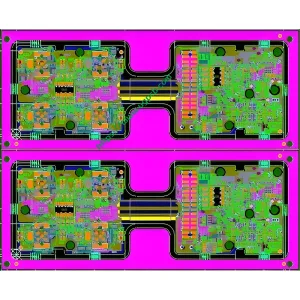

- 組み立てミスを減らす: 正確な設計と自動生産による, フレックス回路により、手動ワイヤーハーネスの人的ミスを排除します. 製造上の誤差を除く, 回路は正確な設計計画で必要なポイントにのみ配線されます。.

コストと時間の効率化

組み立て時間とコストの削減

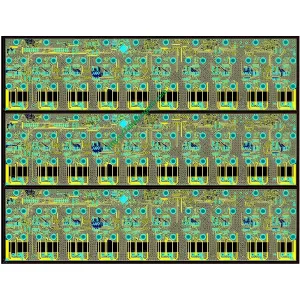

- 組み立て時間とコストの削減: フレックス回路は組み立て時の労力を軽減し、製造エラーを削減します。. フレキシブル回路には、形状を統合する固有の機能があります。, フィット, そして機能. フレックス回路により、配線にかかる高額なコストが不要になります, ラッピング, そしてワイヤーのはんだ付け. 個々のハード PC ボードではなく、完全な相互接続システムを取り付けまたは交換します. 結果として, 配線ミスがなくなる, それにより製造コストを削減します. 組立時間とコストを削減できます, 複雑な回路の少量生産でも、単純な回路の大量生産でも.

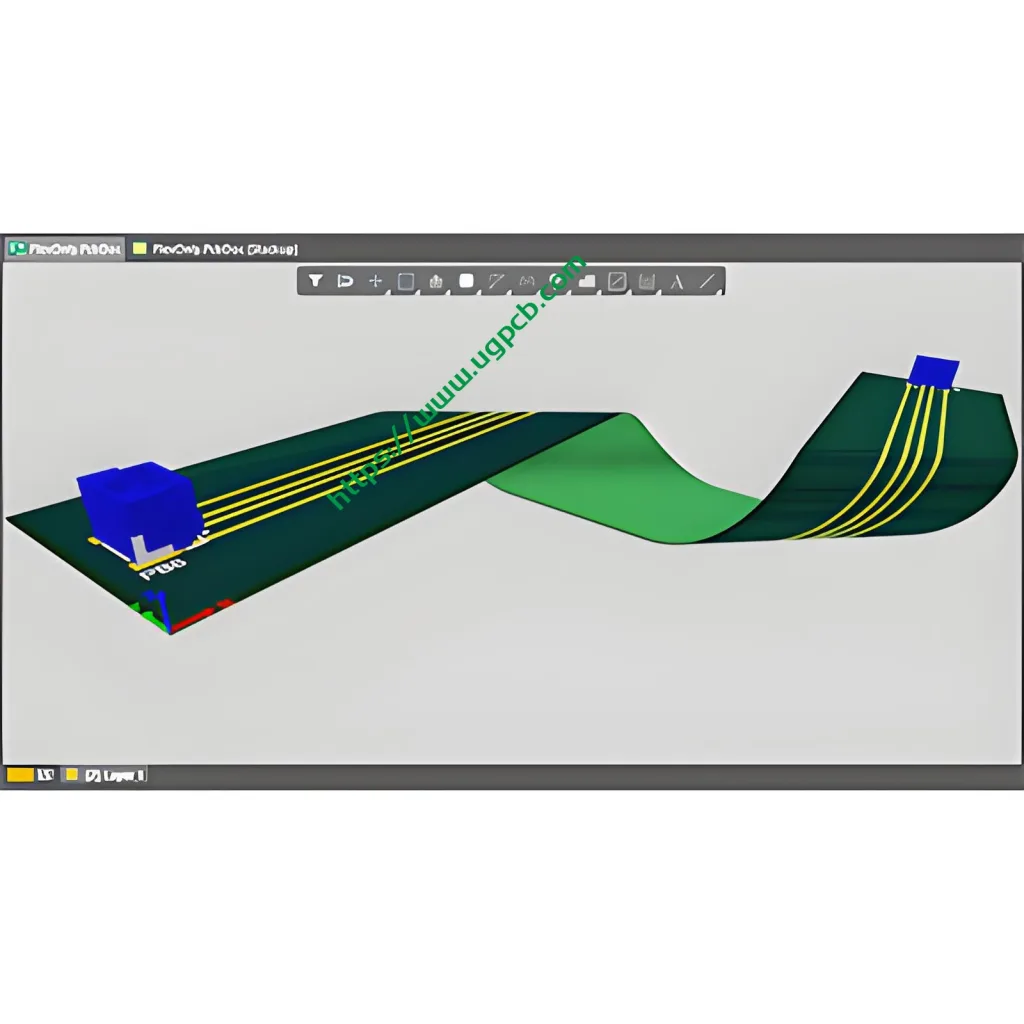

デザインの自由

無限のデザインオプション

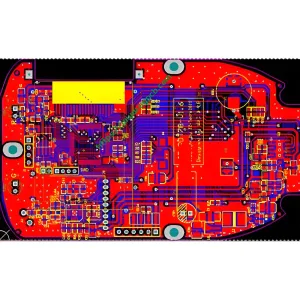

- デザインの自由度: リジッド基板とは異なります, フレックス回路は 2 次元に限定されません. ワイヤーやリボンケーブルと同じくらい柔軟性があるため、, フレックス回路設計のオプションは無限です. UGPCBへ, 私たちは最も複雑な設計課題に取り組むことができることに誇りを持っています. 非常に複雑で想像を絶する構成に合わせて柔軟な回路を設計可能, 最も過酷な環境でも動作できると同時に、.

UGPCBのロゴ

UGPCBのロゴ