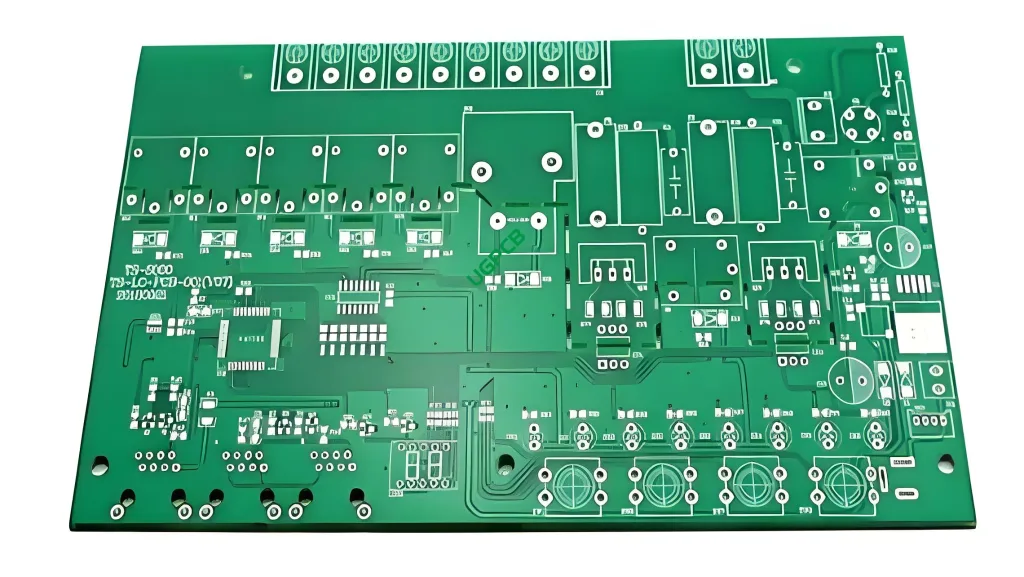

多層PCB車両メインボードの概要

多層PCB車両メインボードは洗練された高性能です プリント基板 自動車アプリケーションで使用するために特別に設計されています. 高度な技術と厳しい品質基準を組み合わせて、車両の最適なパフォーマンスと信頼性を確保する. このメインボードは、現代の自動車の機能において重要な役割を果たしています, さまざまな電子の統合 コンポーネント システムはシームレスにシステムです.

定義と設計の要件

多層PCB車両メインボードは、その多層構造によって定義されています, これにより、複雑な回路と高い成分密度が可能になります. このようなメインボードの設計要件は厳密です, 自動車環境との互換性を確保します. 主要なデザインの側面には、トレース幅と間隔が含まれます, 銅の厚さ, および表面処理, 車両の電子機器の需要を満たすためにすべて調整されています.

作業原則

多層PCB車両メインボードの作業原則には、電気信号の効率的な伝導が含まれます。 PCBの複数の層. 信号は、さまざまな層の銅の痕跡に沿って移動します, VIASとメッキされたスルーホールによって相互接続されています. このアーキテクチャにより、メインボードは最新の車両に必要な高速データ送信と複雑な機能を処理できます.

アプリケーションと分類

多層PCB車両のメインボードの主なアプリケーションは自動車産業にあります, 車両内のさまざまな電子システムの中央ハブとして機能する場所. これらのメインボードは、レイヤー数に基づいて分類されます, 材料組成, OSPなどの特定の機能 (有機はんだ付け性防腐剤) 表面処理, はんだき性を高め、酸化から保護します.

素材とパフォーマンス

KB FR-4材料から構築されています, これらのメインボードは、優れた熱安定性と機械的強度を提供します, 自動車アプリケーションに不可欠です. 製造中の視覚検査における緑または白のカラーコーディングエイズ. 完成した厚さ1.2mmと1オンスの銅の厚さ, 厳しい条件下で信頼できるパフォーマンスのための堅牢なプラットフォームを提供します.

構造と機能

多層PCB車両メインボードの構造には通常、6層が含まれます, それぞれが信号伝送プロセスで特定の目的を果たす. その重要な機能は、TS16949認証の順守です, これにより、製品が自動車アプリケーションの最高品質と信頼性の基準を確実に満たすことが保証されます. さらに, OSP表面処理により、メインボードの耐久性とはんだが向上します.

製造工程

多層PCB車両メインボードの生産プロセスにはいくつかの段階が含まれます, 含む 材料 準備, レイヤープレス, 掘削, 銅メッキ, OSPアプリケーションのような最終仕上げプロセス. 高度な製造技術により、あらゆる側面を正確に制御できます, トレース幅から穴の直径まで, 自動車の使用に適した高品質の出力を保証します.

使用シナリオ

多層PCB車両メインボードは、さまざまな自動車システムで採用されています, エンジン制御ユニットを含む, インフォテインメントシステム, 高度なドライバー支援システム (アダス), もっと. それらは車両に不可欠なコンポーネントです, メーカーが複雑な電子機能を統合できるようにしながら、高い基準の安全性とパフォーマンスを維持できます.

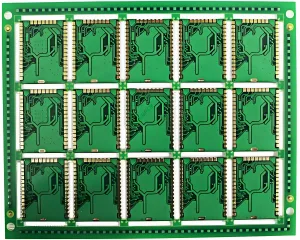

UGPCBのロゴ

UGPCBのロゴ