Overview of PCBA Design for Car Control Systems

UGPCB offers state-of-the-art PCBA design services tailored for automotive control systems, ensuring reliability and efficiency in demanding environments. This solution integrates advanced プリント基板の製造 with assembly (プリント基板) to support critical functions in modern vehicles, such as engine management, safety controls, and infotainment systems. By leveraging high-layer counts and robust materials, UGPCB’s PCBA designs meet stringent automotive standards, providing a foundation for innovative car electronics.

Definition of PCBA in Automotive Applications

プリント基板, または 印刷回路基板アセンブリ, refers to the process of mounting 電子コンポーネント onto a プリント基板 to create a functional circuit system. In car control systems, PCBA acts as the core electronic backbone, facilitating signal processing, 配電, and data communication between vehicle components. This definition underscores the importance of precision in プリント基板設計 and assembly to ensure seamless operation in automotive environments.

Key Design Considerations for Automotive PCBA

Designing a PCBA for car control systems requires attention to several critical factors. 初め, the PCB layer count—up to 12 layers—enables complex routing for high-density circuits, reducing interference and improving signal integrity. Substrate materials like high-TG FR-4 (with TG values such as tg170) provide thermal stability, preventing deformation under high temperatures common in vehicles. 表面仕上げ, including lead-free HASL or immersion gold with a thickness of 2U-5U, enhance solderability and corrosion resistance. Copper thickness options (0.5oz to 6oz) allow for optimized current handling, while solder mask colors (例えば。, 緑, 黒) can be customized for identification and durability. さらに, design must account for electromagnetic compatibility (EMC), vibration resistance, and compliance with automotive standards like ISO 26262.

How PCBA Works in Car Control Systems

The PCBA functions as the central nervous system of a car’s electronic controls. It processes inputs from sensors (例えば。, for engine temperature or brake pressure) and outputs commands to actuators (例えば。, fuel injectors or display units). 例えば, in an engine control unit (ECU), the PCBA manages data via embedded microcontrollers and power components, ensuring real-time response. The 多層PCB 構造, with precise copper traces and vias, facilitates efficient electrical pathways, while the high-TG material maintains performance under hood temperatures, ensuring reliable operation throughout the vehicle’s lifecycle.

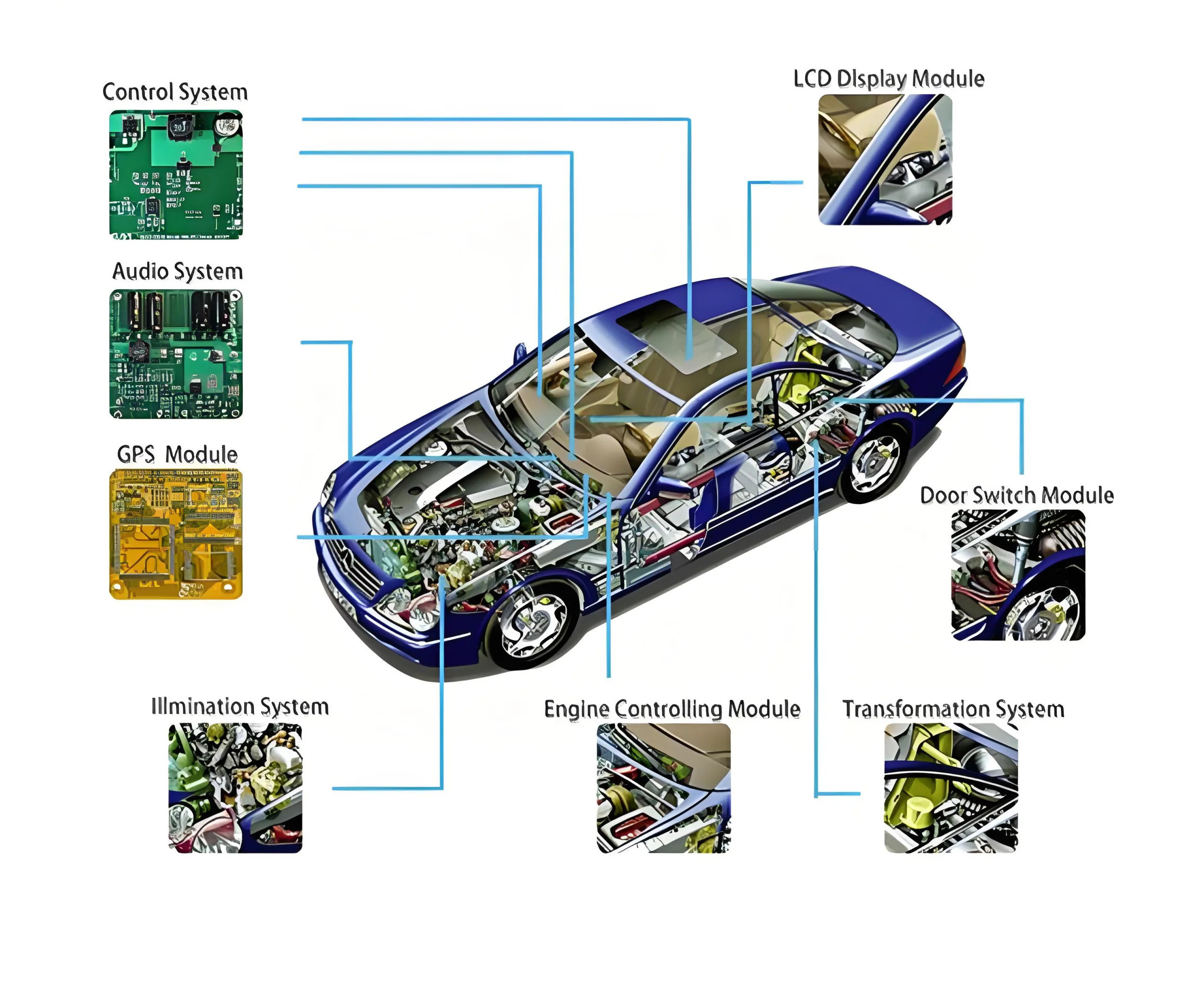

Applications of PCBA in Automotive Electronics

PCBA designs for car control systems are used across various vehicle subsystems. Key applications include engine and transmission control modules, 高度なドライバーアシスタンスシステム (アダス), battery management in electric vehicles, infotainment displays, and climate control units. These PCBA solutions enable features like adaptive cruise control, collision avoidance, and energy efficiency, highlighting their role in enhancing safety, comfort, and sustainability in modern automobiles.

Classification of Automotive PCBA Products

Automotive PCBA can be categorized based on functionality and complexity. Common classifications include power management PCBA (handling high currents with thicker copper), signal processing PCBA (using higher layer counts for data-intensive tasks), and safety-critical PCBA (featuring redundant designs and rigorous testing). UGPCB’s offerings span these categories, with options for custom layer stacks, 材料, and finishes to match specific automotive requirements.

Materials Used in PCBA Manufacturing

The materials selected for PCBA directly impact performance and longevity. UGPCB employs high-TG FR-4 substrates, which offer excellent thermal resistance and mechanical strength for under-hood conditions. Surface finishes like immersion gold provide a flat, reliable surface for component soldering, while lead-free HASL ensures environmental compliance. Copper foils (0.5oz to 6oz) are chosen based on current-carrying needs, and solder masks in colors like green or black protect against moisture and scratches. These materials collectively support durability in harsh automotive environments.

Performance Characteristics of Automotive PCBA

UGPCB’s PCBA designs excel in performance metrics such as thermal stability (handling temperatures up to 170°C with high-TG materials), electrical reliability (minimizing signal loss with controlled impedance), and mechanical robustness (resisting vibration and shock). The inclusion of PCB and PCBA testing—such as automated optical inspection (あおい) and in-circuit testing (ICT)—ensures high yield and compliance with quality standards, reducing failure rates in field operations.

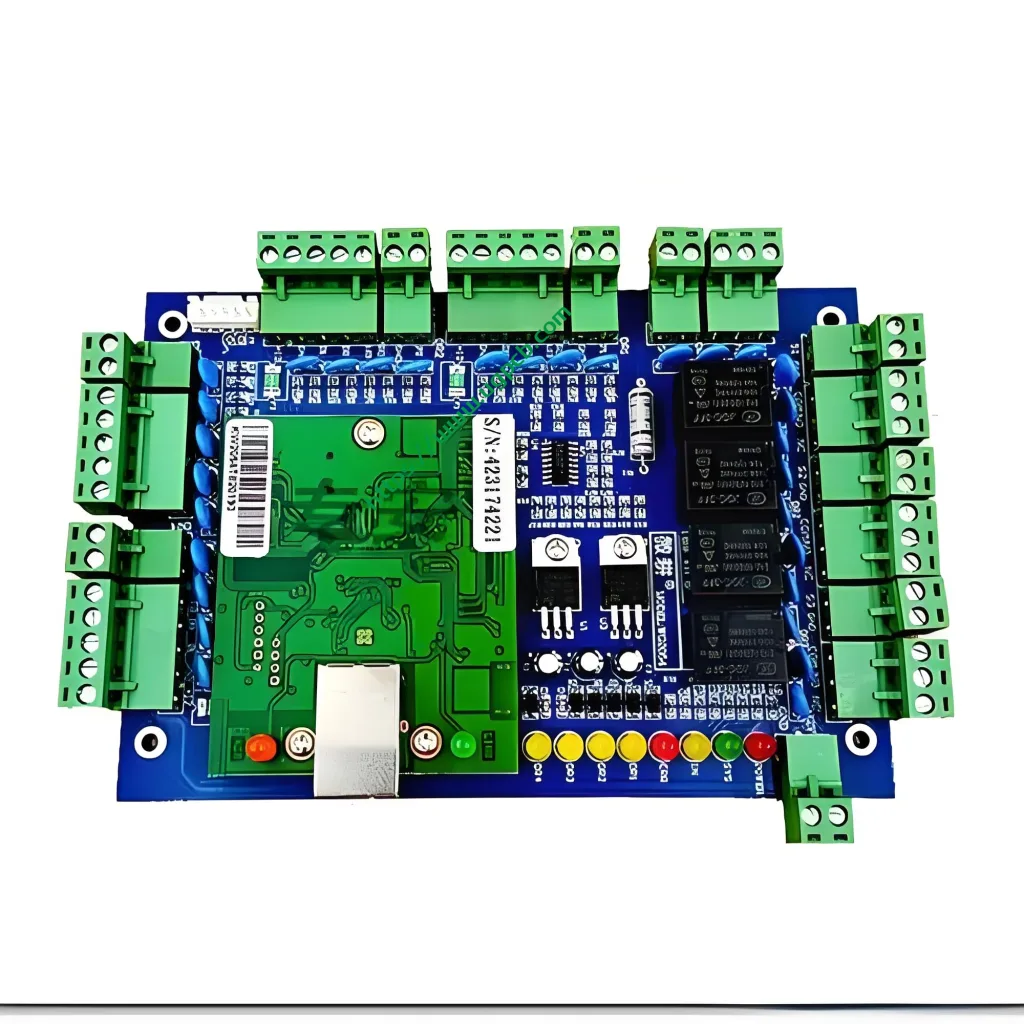

Structural Composition of PCBA for Car Controls

The structure of a PCBA for automotive use typically involves a multilayer PCB stack-up, with inner layers for power and ground planes, and outer layers for component mounting. Vias and through-holes interconnect layers, while the solder mask and silkscreen aid in assembly and identification. The overall design prioritizes compactness and heat dissipation, using materials like high-TG FR-4 to maintain integrity under thermal cycling, which is crucial for long-term reliability in cars.

Features and Advantages of UGPCB’s PCBA Solutions

UGPCB’s PCBA products stand out due to their customizable layer counts (まで 12 レイヤー), versatile material options (including high-TG substrates), and eco-friendly finishes (例えば。, lead-free HASL). Key features include enhanced thermal performance, superior signal integrity, and compliance with automotive safety standards. Advantages include reduced time-to-market through efficient プリント基板 テスト, improved durability in extreme conditions, and cost-effectiveness via optimized design for mass production.

Production Process for Automotive PCBA

The production workflow begins with PCB design and layout, followed by layer lamination using high-TG FR-4 substrates. Copper patterning and plating are done to achieve desired thickness, then surface finishing (例えば。, 浸漬ゴールド) is applied. 成分 assembly follows, involving solder paste application, pick-and-place, そしてリフローはんだ. ついに, rigorous testing—including functional and environmental tests—ensures each PCBA meets automotive specifications before deployment.

Usage Scenarios in Modern Vehicles

UGPCB’s PCBA designs are deployed in various car control scenarios, such as electric vehicle powertrains, where they manage battery and motor controls; アダス, supporting sensors and cameras for autonomous driving; and in-cabin systems, like touchscreen interfaces. These scenarios demand high reliability, and UGPCB’s solutions deliver by combining robust materials with advanced manufacturing techniques, ensuring seamless integration into next-generation automotive technologies.

UGPCBのロゴ

UGPCBのロゴ