Rogers TMMシリーズPCB材料の紹介

Rogers TMMシリーズPCB材料, TMM3などのバリアントを含む, TMM4, TMM6, TMM10, TMM10I, およびtmm13i, セラミックを統合する洗練された複合材料ブレンドを表します, 炭化水素, および熱硬化性ポリマー. このユニークな構成は、高周波マイクロ波アプリケーションのためのこれらの材料の例外的な特性を付与します.

比類のないパフォーマンス特性

電気の安定性と一貫性

TMMシリーズは、誘電率の低い熱変化率を誇っています, 温度の変動に対する最小限の信号の歪みを確保します. その熱膨張係数は、銅ホイルとシームレスに整列します, 一貫した電気性能を促進し、熱不一致に関連する問題を軽減する. これらの属性により、信頼性が最も重要なストリップラインとマイクロストリップ回路設計を要求するのに非常に適しています.

アルミナ基板上の利点の処理

従来のアルミナフィラー基板とは異なります, TMM材料は、大幅な製造上の利点を提供します. 彼らはより大きな銅のクラッディングオプションを促進し、標準のPCB製造プロセスと互換性があります, 特殊な機器や技術を必要とせずに生産効率を高める.

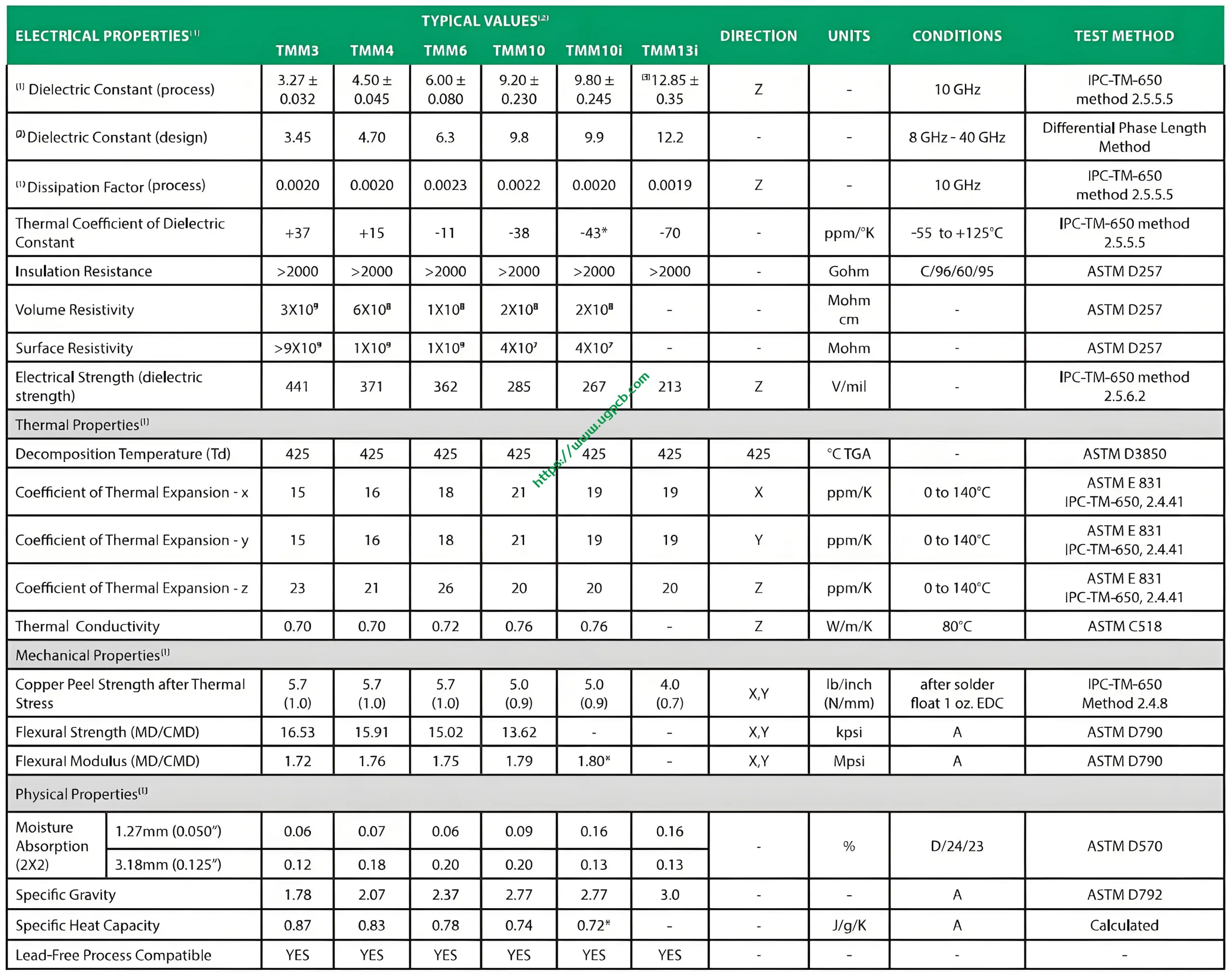

カスタマイズ可能な誘電率と厚さのオプション

TMM材料は、広範囲の誘電率を提供します (3 に 13) と厚さ (0.015 に 0.500 インチ), ±0.0015インチの厳しい耐性レベルを維持しながら. この柔軟性により、設計者はPCBスタックアップを正確に調整するために、特定のアプリケーション要件を満たすことができます.

TMMマイクロ波PCB材料の重要な利点

- 汎用性の高い誘電率範囲: 調整可能な誘電率を使用して、多様な設計ニーズに応えます.

- 優れた機械的強度: クリープフローとコールドフローに耐性があります, さまざまな条件下で構造的完全性を確保します.

- 安定した誘電特性: 温度変化を伴う最小限の誘電率変動, 高精度アプリケーションにとって重要です.

- 熱互換性: 銅箔の熱膨張に一致します, メッキされた穴の信頼性の保護.

- 耐薬品性: 一般的な化学物質の影響を受けません, 生産と組み立て中に完全性を維持します.

- 信頼できるワイヤーボンディング: 熱硬化樹脂組成は、信頼できるワイヤボンディングプロセスをサポートします.

- シンプルさの処理: 標準のPCB製造技術が適用されます, 複雑な方法または独自の方法の必要性を排除します.

- 環境にやさしく、準拠しています: TMM10およびTMM10IバリアントはROHS認定を受けています, 環境の持続可能性へのコミットメントを強調しています.

結論

要約すれば, Rogers TMMシリーズPCB材料は、包括的な利点のために高周波マイクロ波回路基板の領域で際立っています. 比類のない電気の安定性と機械的堅牢性から、処理や環境コンプライアンスの容易さまで, 彼らは、最大限の信頼性とパフォーマンスの一貫性を必要とする高度な電子アプリケーションに理想的なソリューションを提示します.