導入

Tuc TU-900 and TU-900P are high Tg 260°C halogen-free multilayer PCB materials. TU-900 serves as the Core, while TU-900P functions as the PP.

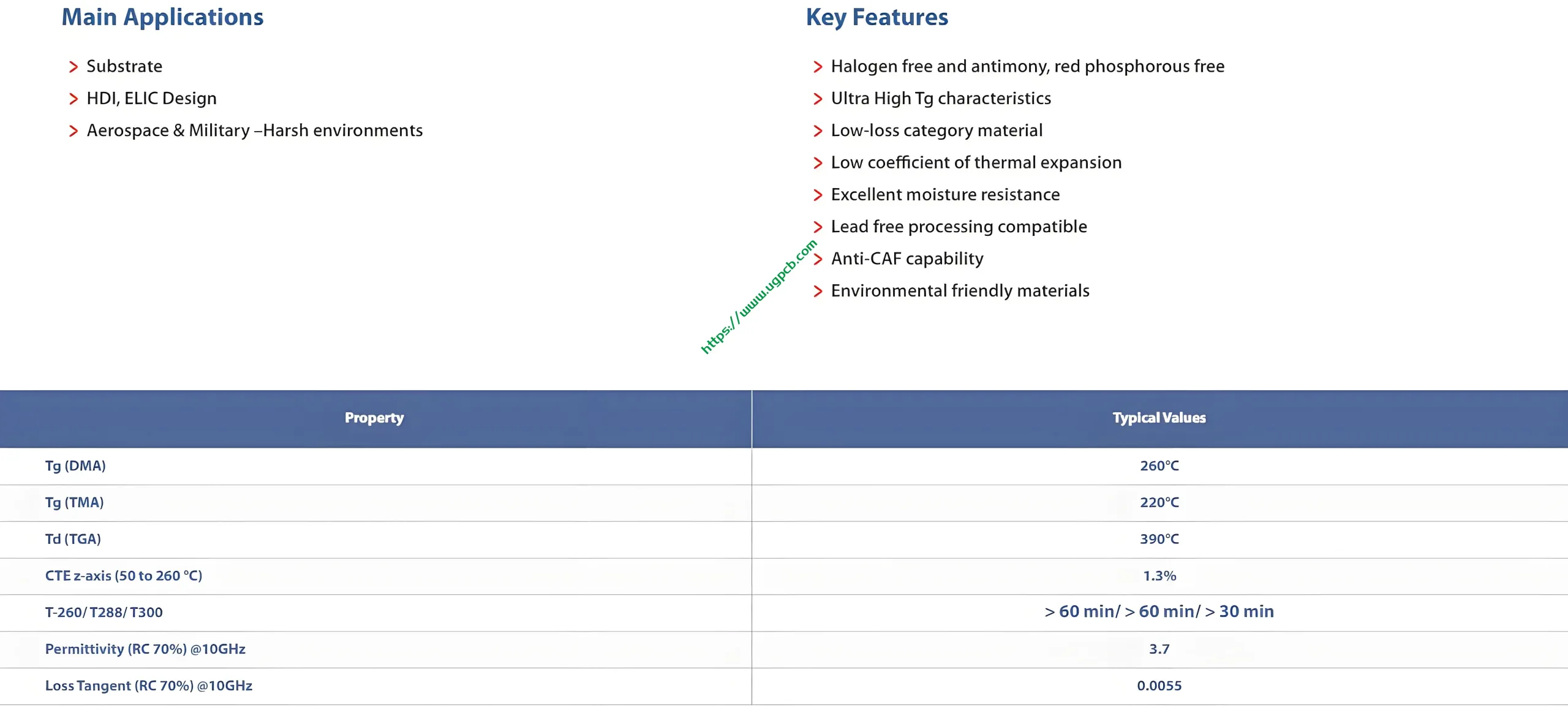

構成と特性

TU-900高TG260°C PCB材料は、BTのような高性能樹脂システムとアルカリを含まないガラス生地から作られています. ハロゲンを含まない多層PCB設計を誇っています, 高弾性率, 高い信頼性, 低dk/df, 低損失電気特性.

Design and Application

TU-900 and TU-900P multilayer PCB materials are tailored for high-reliability multi-layer PCB boards, IC substrates or SiP package substrates, radio frequency PCBs, and ultra-thin HDI PCB boards. They are suitable for PCB boards that demand strict X, Y dimensional stability, low board deformation, or operation in excessively harsh environments.

追加のプロパティ

TU-900 PCB material further exhibits excellent chemical resistance, high rigidity, low thermal expansion, and outstanding long-term reliability and CAF performance.

Data Sheet

Tuc TU-900 / TU-900P PCB materials Data Sheet

Industry Certification

Tuc TU-900 and TU-900P possess industry certification IPC-4101 with model names /127, /128, /130. They have a UL name-no ANSI rating, UL file number E189572, a flammability rating of 94V-0, and a maximum operating temperature of 150°C.

標準的な可用性

Tuc TU-900 and TU-900P are available in thicknesses ranging from 0.0012″ [0.03mm] to 0.062″ [1.58mm], シートまたはパネルフォーム. Copper foil cladding ranges from 1/3 に 3 ounces. Prepreg is available in roll or panel form, with Glass styles including 1017, 1027, 1037, 1067, 1078, 3313, そして 2116, among others available upon request.

UGPCBのロゴ

UGPCBのロゴ