A mere 0.5mm² crack in a BGA solder pad can brick a premium smartphone into a “white-screen paperweight” – while conventional underfill encapsulation merely disguises this critical PCB reliability threat. As smartphones rapidly evolve toward ultra-thin designs and high-performance specs, BGA pad cracking has become the Damocles’ sword hanging over PCBA manufacturing. When a $1,000+ mobile phone PCB assembly becomes scrap due to micro-cracks or market return rates surge 30% from Type V fractures, we must ask: Is underfill truly the ultimate solution?

1. BGA Pad Cracking: The Invisible Killer of Electronics

H3: 1.1 Failure Definition & Five Fracture Types

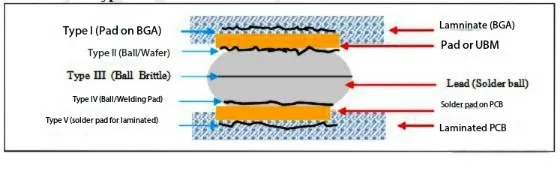

BGA pad cracking refers to the separation between IC chips and PCB pads under mechanical/thermal stress. Five fracture types are classified by location:

| Type | Failure Location | Prevalence | Primary Triggers |

|---|---|---|---|

| Type I | Chip substrate layer | 12% | Tumbling tests, mechanical shock |

| Type II | BGA pad-solder interface | 18% | Thermal cycling |

| Type III | Lead-free solder ball | 25% | Drop impact, thermal shock |

| Type IV | Solder-PCB pad joint | 28% | Reflow profile mismatch |

| Type V | Pad-substrate separation | 17% | Structural deformation, material degradation |

1.2 Stealth Nature & Destructive Impact

Traditional SMT inspection detects <5% of pad cracks due to:

-

Micro-crack sizes (5-50μm) obscured in multilayer PCBs

-

Electrical continuity often maintained despite fractures

-

Underfill masks cracks without halting propagation, requiring destructive removal during rework

2. Root Cause Analysis Across PCBA Workflow

2.1 Material Origin: Copper Foil Crystal Structure Divergence

Experimental data reveals: Copper foil with specialized “grape-like” nodular structures delivers 18.5% higher adhesion than conventional crystals.

2.2 PCB Substrate Limitations: FR4’s Thermal Endurance Crisis

Lead-free soldering demands peak temperatures of 248°C (+33°C vs traditional processes). Standard FR4’s Tg of 130-140°C causes:

-

Z-axis CTE >300 ppm/°C

-

T288 delamination time <3 min (Industry requires >5 min)

Critical Formula: Thermal Stress = E × α × ΔT

Where:

σ = Thermal stress (MPa), E = Elastic modulus (GPa),

α = CTE (ppm/°C), ΔT = Temperature change (°C)

*High-CTE substrates generate 1.8× more stress at ΔT=100°C*

2.3 PCB Design Pitfalls: Overlooked Mechanical Stress

Analysis of 7,000 failed units in Russian markets shows:

-

0.80mm boards failed 3.2× more than 1.00mm boards

-

T-card slots increased PCBA cracking risk by 47%

-

Large components under BGA zones caused asymmetric thermal deformation

3. Critical PCB Process Control Breakthroughs

3.1 PCB Manufacturing Optimization Matrix

| Process | Conventional | Optimized | Improvement |

|---|---|---|---|

| Copper foil | Standard nodules | Grape-like crystals | Adhesion ↑18.5% |

| Plating thickness | 18-23μm | ≥30μm | Tensile ↑32% |

| Surface prep | Belt sanding | Micro-etch + spray | Copper loss ↓60% |

| Solder mask opening | Circular | Hexagonal | Paste flow ↑40% |

3.2 Reflow Profile Revolution

Failure root: Standard reflow spends only 12s cooling from 190°C→130°C, causing rapid contraction.

Solution: Extend dwell time above Tg by 150%, reducing thermal stress by 35%.

4. Comprehensive PCBA Solution Database

4.1 Design Innovations

-

Pad geometry: Convert peripheral pads to oval (long axis +0.1mm)

-

Stackup design: Add localized copper balance layers under BGAs

-

Clearance rule: Prohibit large components within 3mm of BGA zones

4.2 Material Upgrade Path

-

Specify FR4 with Tg ≥170°C

-

Control copper foil Rz (roughness) at 3.5-5.0μm

-

Adopt low-CTE (<2.5%) high-toughness resin systems

4.3 Process Control Redlines

-

Copper plating ≥30μm (validated)

-

OSP panel spacing >5mm (acid trapping prevention)

-

Test fixture pressure ≤7kg/cm², pin life <500k cycles

-

150-180°C reflow zone dwell ≥90 seconds

5. Future Technology Roadmap

As HDI PCBs advance toward 0.4mm thickness and BGA pads shrink below 0.2mm, breakthroughs required:

-

Nano-scale copper treatment: Magnetron-sputtered adhesion layers

-

CTE-adaptive substrates: Temperature-responsive polymer composites

-

AI process monitoring: Real-time solder joint health prediction

Conclusion: Reliability is Designed In

BGA pad cracking constitutes system-level reliability failure. Post-implementation results:

-

Tumbling test pass rate: 82% → 99.6%

-

Market return rate: ↓70%

-

Cost reduction: $1.20/board via underfill elimination

*Remember: A 0.1kgf increase in per-pad adhesion delivers exponential reliability gains. This transcends process refinement – it embodies the ultimate pursuit of zero-defect manufacturing.*

In the microscopic realm of solder pads, grape-like copper crystals weave nano-scale protective networks, while lead-free spheres perform precision dances within hexagonal mask openings. The electronics reliability revolution begins with unwavering commitment to every 0.01mm.