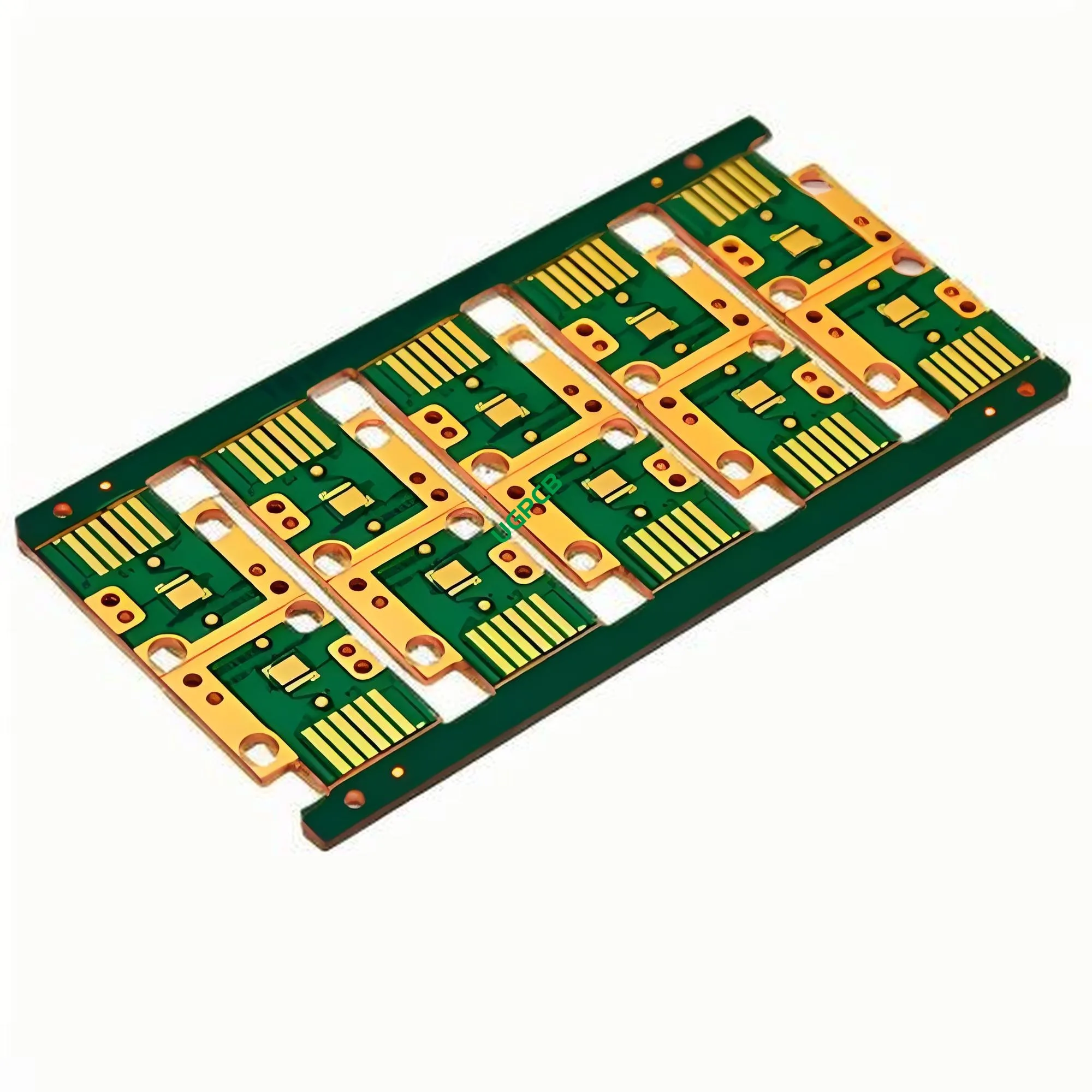

Overview of 12OZ Heavy Copper PCB for Power Supply

The 12OZ Heavy Copper PCB for power supply is a specialized product designed to meet the stringent requirements of power supply applications. This type of PCB offers high current-carrying capacity, thermal stability, and reliability, making it an ideal choice for various power electronics devices.

Definition

A 12OZ Heavy Copper PCB for power supply is a printed circuit board specifically designed to support the functions of a power supply unit. It consists of multiple layers of conductive and insulating materials, providing complex electrical pathways and connections essential for the operation of the power supply. The term “12OZ” refers to the copper weight, indicating that the copper layer is significantly thicker than standard PCBs, allowing it to handle higher currents and dissipate more heat.

Design Requirements

When designing a 12OZ Heavy Copper PCB for power supply, several key requirements must be met:

- Material Quality: High-quality FR4 material is essential for durability and thermal stability.

- Layer Configuration: A 2-layer design is standard, allowing for efficient routing of power and ground planes.

- Copper Thickness: A copper thickness of 1OZ ensures adequate conductivity and thermal management.

- Surface Treatment: Immersion gold surface treatment enhances connectivity and corrosion resistance.

- Trace/Space Dimensions: Minimum trace and space dimensions of 40mil (1mm) are required for precise circuit patterns.

- Special Features: 2OZ Heavy Copper PCB design is often incorporated for specific component placement and soldering requirements.

Working Principle

The 12OZ Heavy Copper PCB for power supply operates based on the principles of electrical conductivity and thermal management. Conductive layers form the pathways for electrical signals, while insulating layers prevent unwanted interactions between these signals. The heavy copper layer provides low resistance paths for high currents and helps dissipate heat generated by power components. The immersion gold surface treatment provides excellent connectivity and protects against environmental factors.

Applications

This type of PCB is primarily used in power supply units, which are crucial components in various electronic devices such as computers, servers, telecommunications equipment, and industrial machinery. These include:

- Power adapters and chargers

- DC-DC converters

- AC-DC power supplies

- Uninterruptible Power Supplies (UPS)

- Motor controllers

Classification

12OZ Heavy Copper PCBs for power supply can be classified based on their specific features and intended use, such as:

- High Current Carrying Boards: For handling large currents in power distribution systems.

- Thermal Management Boards: To efficiently dissipate heat generated by power components.

- Control Boards: For managing and controlling various functions in power electronics systems.

Materials

The primary materials used in the construction of a 12OZ Heavy Copper PCB for power supply include:

- Base Material: FR4, a flame-retardant fiberglass material known for its excellent dielectric properties and mechanical strength.

- Conductive Material: Copper, used for the conductive traces.

- Surface Treatment: Immersion gold, which enhances connectivity and provides corrosion resistance.

Performance

The performance of a 12OZ Heavy Copper PCB for power supply is characterized by:

- High Current-Carrying Capacity: Due to the thick copper layer, which allows it to handle higher currents without significant voltage drop or overheating.

- Enhanced Thermal Stability: The heavy copper layer helps dissipate heat more effectively, maintaining stable operating temperatures.

- Reliable Connectivity: Ensured by the immersion gold surface treatment.

- Durability: Enhanced by the robust FR4 base material.

- Electrical Efficiency: Minimized signal loss and interference due to optimized layer configuration.

Structure

The structure of a 12OZ Heavy Copper PCB for power supply consists of:

- Two Layers of Conductive Material: Alternating with insulating layers.

- Immersion Gold Surface Treatment: For enhanced connectivity and protection.

- Heavy Copper Design: For specific component placement and soldering requirements.

Features

Key features of the 12OZ Heavy Copper PCB for power supply include:

- Advanced Copper Weight: 2OZ Heavy Copper for superior current-carrying capacity.

- High Precision: With minimum trace and space dimensions of 40mil (1mm).

- Customizable Color Options: Available in black or white.

- Standard Thickness: With a finished thickness of 2.0mm.

Production Process

The production process for a 12OZ Heavy Copper PCB for power supply involves several steps:

- Material Preparation: Selecting and preparing FR4 sheets and copper foil.

- Layer Stacking: Combining the copper and insulating layers.

- Etching: Removing excess copper to form the desired circuit pattern.

- Plating: Applying immersion gold surface treatment.

- Lamination: Combining the layers under heat and pressure.

- Drilling: Creating holes for through-hole components and vias.

- Solder Mask Application: Protecting the circuit from solder bridges and environmental factors.

- Silkscreen Printing: Adding text and symbols for component placement and identification.

- Quality Control: Ensuring the PCB meets all design specifications and standards.

Use Scenarios

The 12OZ Heavy Copper PCB for power supply is ideal for scenarios where:

- High current-carrying capacity is crucial.

- Reliable and durable connections are required.

- Effective thermal management is necessary to maintain stable operating temperatures.

- Advanced surface treatment is needed for enhanced performance