Light LED PCBA Overview

Introduction

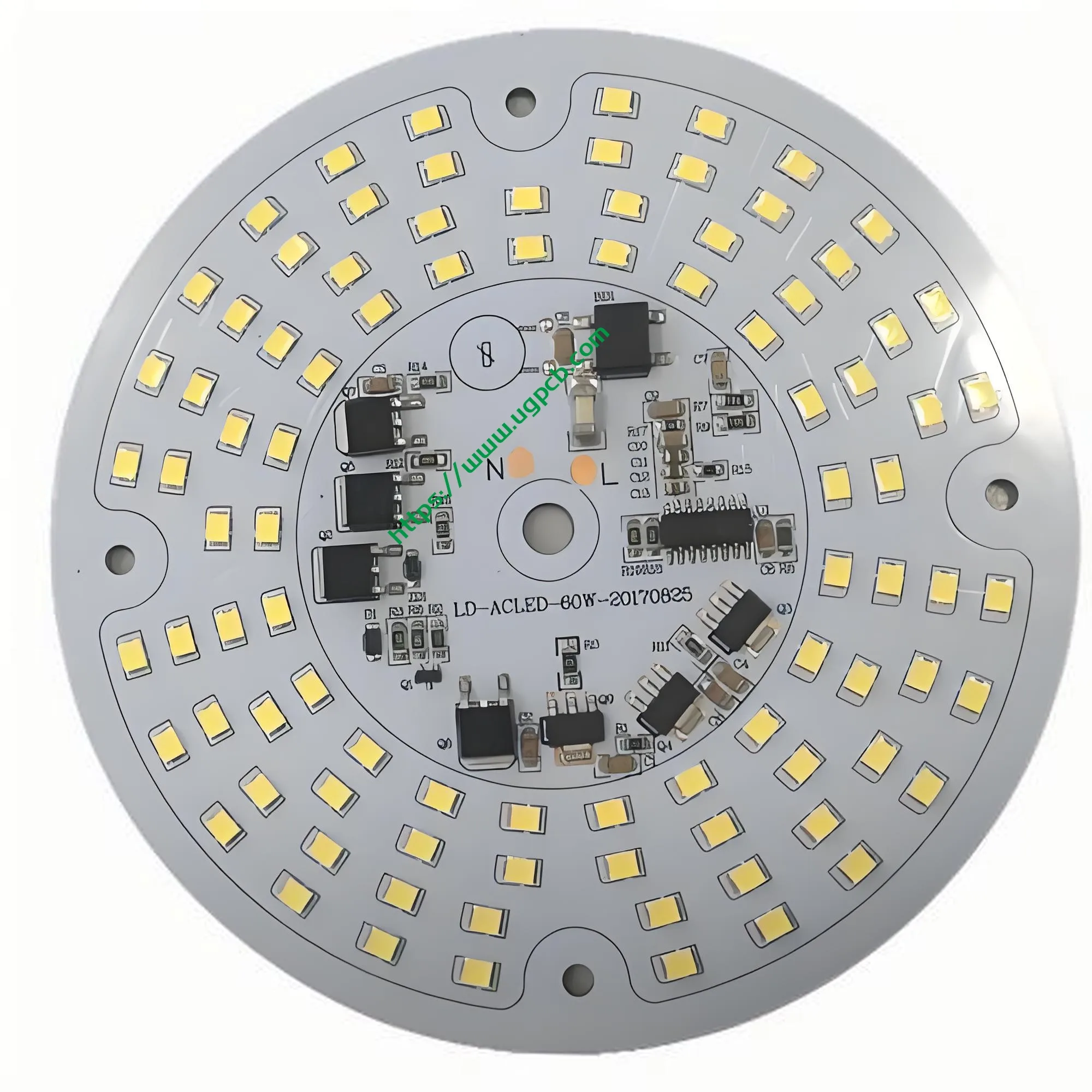

The Light LED PCBA is a compact and efficient printed circuit board assembly designed for LED lighting applications. This PCBA features 1-2 layers of conductive material, making it suitable for simpler circuit designs while maintaining high performance and reliability.

Definition

A Light LED PCBA refers to a printed circuit board assembly that incorporates surface mount technology (SMT) or through-hole technology (THT) components specifically for LED lighting applications. The PCBA includes all necessary electronic components soldered onto the PCB, ready for integration into an LED lighting system.

Working Principle

The working principle of a Light LED PCBA involves using conductive copper traces on a non-conductive substrate to create electrical pathways. These pathways connect various electronic components such as LEDs, resistors, and capacitors. When electrical current flows through these pathways, it powers the LEDs, causing them to emit light.

Applications

This type of PCBA is widely used in various LED lighting applications, including:

- Residential and commercial lighting fixtures

- Automotive lighting systems

- Signage and display lighting

- Decorative and architectural lighting

Classification

PCBAs can be classified based on several criteria:

- By number of layers: Single-layer, double-layer, or multi-layer (including 1-2 layers)

- By type of components: Through-hole, surface mount, or a combination of both

- By substrate material: FR-4, aluminum, copper, etc.

Materials

The primary materials used in the construction of a Light LED PCBA include:

- Substrate: FR-4, aluminum, copper

- Surface Treatment: HASL lead-free / OSP (Organic Solvent Protection)

- Solder Resist: White

- Copper Thickness: 0.5oz-2oz

- Silk Screen Color: Black

Performance

The performance of this PCBA is characterized by:

- High thermal conductivity due to the copper layers

- Low signal loss and high signal integrity

- Resistance to environmental factors such as humidity and temperature variations

- Compliance with RoHS and lead-free assembly standards

Structure

The structure of a Light LED PCBA typically includes:

- Conductive copper traces on a non-conductive substrate

- Surface mount and/or through-hole components soldered onto the PCB

- A white solder mask covering the top layer for protection and identification

- A black silk screen for labeling and component identification

Features

Key features of this PCBA include:

- Compact and lightweight design suitable for space-constrained applications

- Superior thermal management capabilities

- Enhanced durability and longevity in various lighting environments

- Compatibility with a wide range of LED components

Production Process

The production process of a Light LED PCBA involves several steps:

- Design: Using specialized software to create the circuit layout and component placement.

- Material Preparation: Selecting and preparing the substrate, copper foil, and other materials.

- Layer Stacking: Stacking the layers of copper and dielectric materials.

- Via Drilling: Drilling holes through the stacked layers for vias (if applicable).

- Plating: Plating the vias with copper to ensure electrical connectivity.

- Etching: Removing excess copper to form the desired circuit pattern.

- Component Placement: Soldering surface mount and/or through-hole components onto the PCB.

- Testing: Conducting rigorous testing to ensure functionality and compliance with standards.

- Final Inspection: Ensuring the PCBA meets all quality and performance criteria.

Use Cases

Common use cases for the Light LED PCBA include:

- Residential and commercial lighting fixtures where energy efficiency and longevity are crucial

- Automotive lighting systems requiring high reliability and performance

- Signage and display lighting in retail and advertising applications

- Decorative and architectural lighting projects needing custom designs and high aesthetics

Conclusion

The Light LED PCBA is an advanced and reliable solution for various LED lighting applications. Its compact design, high-performance materials, and compliance with industry standards make it an ideal choice for engineers and manufacturers seeking efficient and durable electronic solutions.