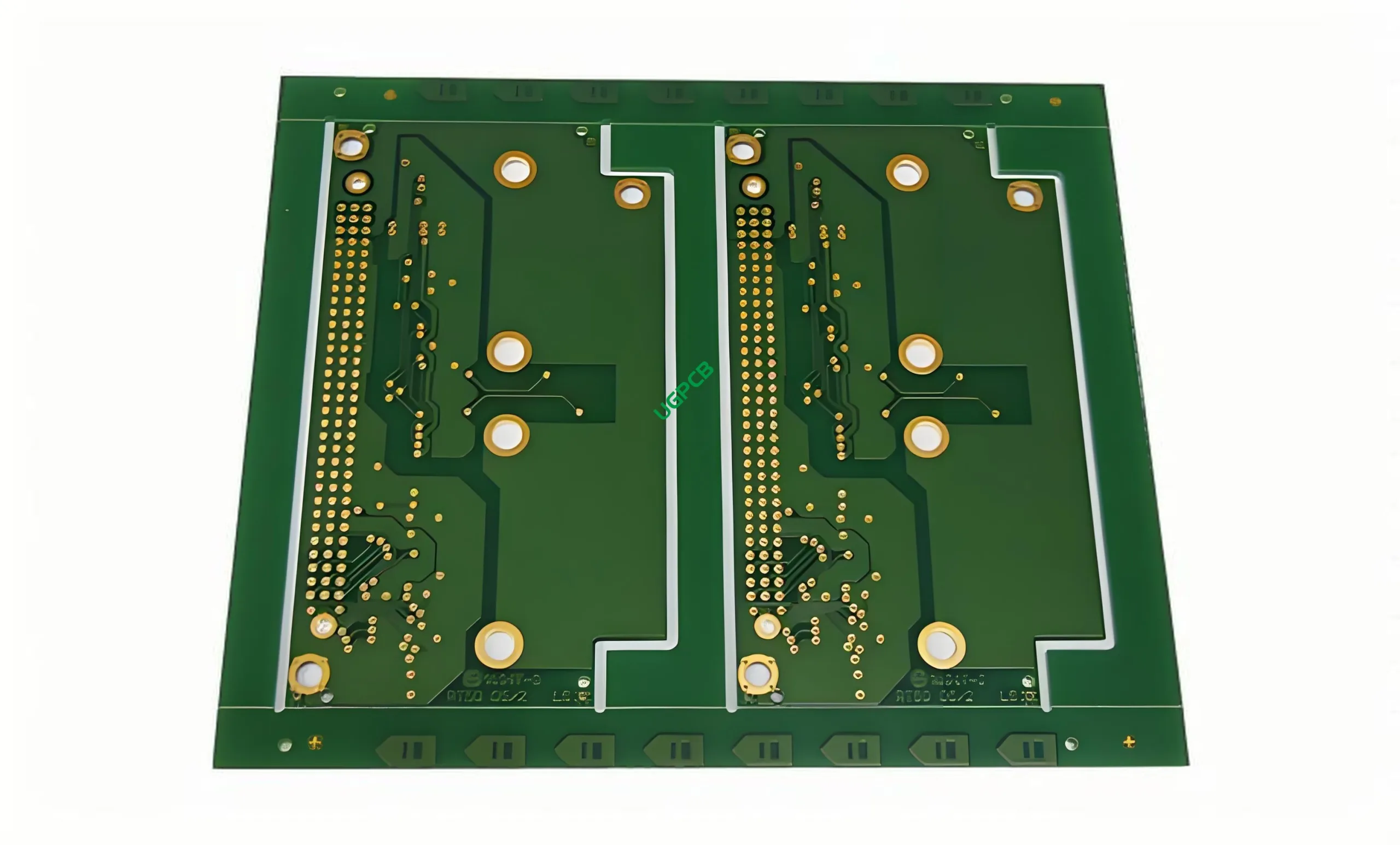

Overview of the 36-Layer High TG Backplane PCB

The 36-Layer High TG Backplane PCB is a high-density, multilayer printed circuit board (PCB) designed for backplane applications. Esse PCB is ideal for complex electronic systems that need to manage high power and signal integrity.

What is a 36-Layer High TG Backplane PCB?

A 36-Layer High TG Backplane PCB is a printed circuit board (PCB) com 36 layers of conductive material separated by insulating layers, specifically designed for backplane applications. The term “High TG” refers to the glass transition temperature, indicating the PCB’s ability to withstand high temperatures without losing its mechanical and electrical properties.

Requisitos de design

The design requirements for a 36-Layer High TG Backplane PCB are stringent to ensure its performance and reliability:

- Material: Alto TG FR4, chosen for its excellent electrical and thermal properties.

- Contagem de camadas: 36 layers to accommodate complex and dense circuit designs.

- Cor: Green/White for easy identification and aesthetic appeal.

- Espessura Acabada: 2.4mm to provide structural integrity and durability.

- Espessura do Cobre: 1OZ to ensure adequate conductivity and heat dissipation.

- Tratamento de superfície: O ouro de imersão para melhorar a solda e a resistência à corrosão.

- Traço mínimo e espaço: 4mil(0.1milímetros) Para suportar padrões de circuito fino.

- Característica: Alta multicamada, Panasonic M6 PCB material, known for its high reliability and performance.

Como funciona?

The 36-Layer High TG Backplane PCB works by providing a platform for various electronic components to be interconnected through conductive pathways. Esses caminhos, ou traços, são feitos de cobre e são gravados no quadro. The high TG FR4 material ensures that the PCB can withstand high temperatures without losing its mechanical and electrical properties, while the immersion gold surface treatment ensures that these traces remain conductive and resistant to corrosion.

Aplicações

The primary application of the 36-Layer High TG Backplane PCB is in backplane applications where it manages and regulates the flow of electrical signals. Isso inclui:

- Data communication devices

- Equipamento de rede

- Industrial control systems

- Telecommunication infrastructure

Classificação

Com base em seus recursos e aplicativos, the 36-Layer High TG Backplane PCB can be classified as a high-speed digital PCB designed for backplane applications. This classification highlights its capability to handle high-frequency signals and provide stable electrical connections.

Composição de materiais

The core material used in the 36-Layer High TG Backplane PCB is High TG FR4, a high-performance composite material known for its excellent mechanical, térmico, e propriedades elétricas. This material ensures that the PCB can withstand the demands of backplane applications.

Características de desempenho

The performance characteristics of the 36-Layer High TG Backplane PCB include:

- Alta integridade do sinal

- Baixa perda de sinal

- Gerenciamento térmico superior

- Força mecânica robusta

- Estabilidade a longo prazo

Detalhes estruturais

The structural details of the 36-Layer High TG Backplane PCB are as follows:

- Contagem de camadas: 36 camadas

- Espessura Acabada: 2.4milímetros

- Espessura do Cobre: 1OZ

- Tratamento de superfície: Imersão Ouro

- Traço mínimo e espaço: 4mil(0.1milímetros)

- Característica: Alta multicamada, Panasonic M6 PCB material

Recursos e benefícios

The key features and benefits of the 36-Layer High TG Backplane PCB include:

- Interconectividade de alta densidade

- Excelente integridade do sinal

- Construção mecânica robusta

- Desempenho confiável de longo prazo

- Opções de cores estéticas (Verde/Branco)

Processo de Produção

The production process of the 36-Layer High TG Backplane PCB involves several steps including:

- Seleção de material: Choosing high-quality High TG FR4 material.

- Empilhamento de camada: Organizando o 36 camadas com precisão.

- Gravura: Removendo o excesso de cobre para formar os padrões de traços desejados.

- Aplicação de máscara de solda: Applying a solder mask layer to protect the copper traces.

- Revestimento: Aplicando tratamento de superfície de ouro de imersão.

- Conjunto: Incorporando PTHs e Vias para interconexões de camada.

- Teste: Garantir que o PCB atenda a todas as especificações de desempenho.

Casos de uso

The 36-Layer High TG Backplane PCB is used in various scenarios such as:

- Backplane applications in data centers

- High-speed networking equipment

- Industrial automation systems

- Telecommunication infrastructure