UGPCB: Expert in One-Stop PCB Design, Production & PCBA Assembly Solutions

In the rapidly evolving electronics industry, high-quality Plăci de circuite tipărite (PCB -uri) serve as the cornerstone for achieving exceptional electronic product performance. As an industry-leading one-stop solution provider, UGPCB leverages its comprehensive strengths in PCB design capabilities, advanced manufacturing processes, PCBA assembly technologies, and extensive PCB technical resource sharing to deliver end-to-end services—from conceptualization to mass production—for global clients.

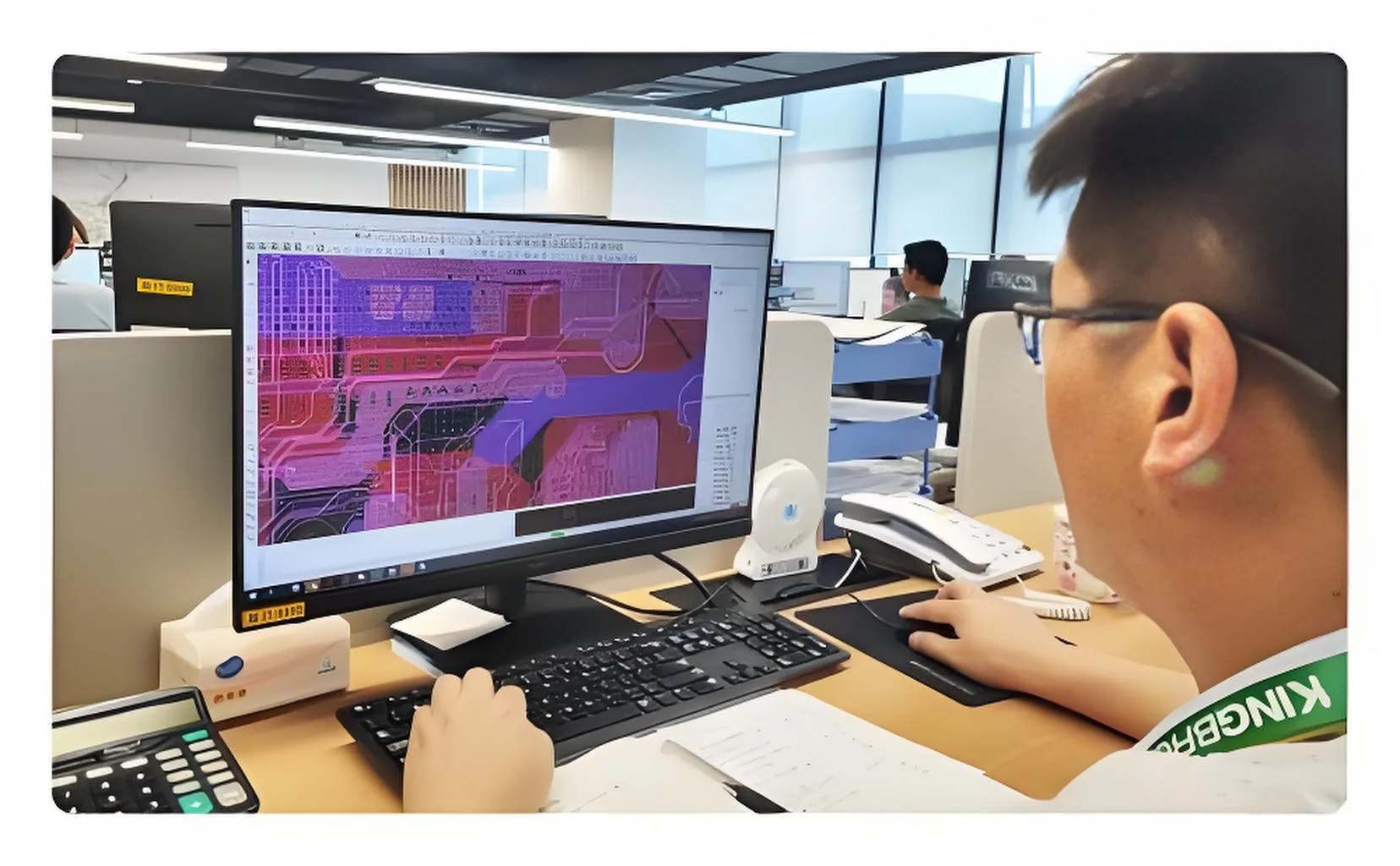

1. Superior PCB Design Expertise

UGPCB boasts an experienced Design PCB team capable of handling diverse design complexities.

- Hierarchical Schematic & Layout Design

Our engineers master multiple design tools for efficient hierarchical schematic design and multi-layer layout development. Junior engineers are trained to manage single/double/multi-layer PCBs with up to 400 components and 1000 nets, ensuring rational layout/routing while addressing thermal management, structural requirements, EMI/EMC compliance, and aesthetic standards. Senior engineers tackle more complex design challenges. - Complex Packaging & High-Speed Design

We create precision packages (De ex., RJ-45 connectors with LEDs) based on specifications and physical prototypes, ensuring exact dimensions for pads and shapes. Pentru high-speed PCBs, we adhere to strict routing protocols, implement controlul impedanței, and optimize signal integrity to guarantee reliable high-frequency transmission.

Impedance Control Formula:

Z₀ = [87 / √(ε_r + 1.41)] × ln[5.98h / (0.8w + t)]

Unde = characteristic impedance, ε_r = dielectric constant, = distance between signal layer and reference plane, = trace width, = trace thickness. Precise parameter control ensures signal integrity. - Proiectare pentru producție (DFM)

We integrate DFM principles from the design phase, aligning with production requirements to eliminate defects and enhance efficiency/quality. Designers seamlessly import/export mechanical drawings, ensuring structural compatibility for flawless production transitions.

2. Advanced PCB Manufacturing Processes

UGPCB invests in cutting-edge equipment and technologies to ensure precision, calitate, and reliability in PCB production.

- Multi-Layer Board Capabilities

We support 4-100 layer multi-layer PCBs and advanced HDI designs with technical specifications:- Min. trace/space: 1.5mil/1.5mil (ensuring high-frequency integrity)

- Material options: FR4, high-frequency substrates (Rogers, Taconic, etc.)

- Surface finishes: De acord, OSP, Argint de imersie, etc.

- Hole precision: ± 0,05mm (enabling high-density interconnects)

- Automated Production & Quality Inspection

Our automated lines feature intelligent exposure machines and laser drilling to minimize human error and enhance consistency. Quality systems include:- Aoi: Automated defect/deviation detection

- Flying Probe: Circuit continuity/performance validation

- 24/7 in-line monitoring: Achieving >99% yield rates per batch

3. High-Precision PCBA Assembly Services

UGPCB offers end-to-end PCBA assembly by integrating SMT and through-hole technologies for reliable assembly.

- SMT Assembly Advantages

- Precision: ±0.025mm accuracy via optical alignment/flying probe, handling 0402 components, BGA, Qfn, etc.

- Soldering Excellence: Reflow profiling optimizes lead-free solder joints, extending thermal fatigue life >1000 cicluri.

- Efficiency: Automated lines achieve tens of thousands of placements/hour with >99.5% first-pass yield.

- Quality Testing & Reliability Validation

Our testing suite includes:- de mediu: Thermal cycling/thermal shock tests

- Mecanic: Vibration/shock simulation

- Electrical: 100% ICT coverage

4. Extensive PCB Technical Resources

UGPCB promotes knowledge sharing with downloadable resources:

- Process standards: New product fabrication reports

- Design guidelines: Company-specific design norms

- Substrate data: Panasonic and other material specs

These resources empower clients/engineers to enhance PCB design skills and tackle challenges.

5. Aplicații industriale & Success Stories

UGPCB solutions serve premium sectors:

- Electronică auto

Supplying PCBs for EV control systems and ADAS modules, ensuring reliability in harsh environments. - Medical Devices

Certified PCBs for precision monitors, endoscope boards, etc., meeting strict safety/reliability standards. - Aerospațial

High-performance PCBs for satellite comms and flight controllers, operating in extreme conditions.

Studiu de caz: A global industrial robotics leader received 100,000 6-layer PCBs within 2 weeks with <0.1% defect rate, enabling quarterly capacity targets.

6. Technological Evolution & Perspectivele viitoare

AI expansion drives global infrastructure growth, boosting PCB demand. Prismark forecasts 2024-2029 CAGR of 19.1% for AI server HDI PCBs and 17.4% pentru 18+ layer boards—far exceeding the industry’s 5.2% average.

UGPCB embraces trends through R&D.:

- 78.46% YOY R&D growth to solidify leadership

- 100+ layer multi-layer board capabilities

- Mass production breakthrough for 6-stage 24-layer HDI

- Development of 8-stage 28-layer HDI & 16-layer Any-layer HDI

De ce să alegeți UGPCB?

- Integrated Solutions: Full-service from design to PCBA

- Asigurarea calității: Advanced equipment/strict QC

- Rapid Delivery: 3-5 day prototype turnaround, 40% faster bulk production

- Eficiența costurilor: 15% procurement savings via scale/lean management

- Technical Support: 24/7 dedicated team

UGPCB delivers high-quality PCB design, fabricație, and assembly services globally. Whether you need simple double-sided boards or complex HDI/substrat IC solutions, we provide expert, reliable outcomes.

Contact us today for tailored solutions and professional quotes. Let UGPCB’s expertise and efficiency safeguard your product success!