Introducere

For those who have not worked in an SMT (Tehnologia de montare a suprafeței) factory, the basic processes and key steps involved in SMT manufacturing may remain a mystery. Astăzi, I will introduce the three main processes of SMT manufacturing to provide a clearer understanding of this technology.

Overview of SMT Manufacturing

SMT manufacturing is currently the most popular technology and process in the electronic assembly industry. The process flow of SMT manufacturing is complex, with variations depending on the product. Cu toate acestea, the basic flow generally includes: incoming material inspection, programming, printing, inspecţie, mounting, pre-oven inspection, reflow soldering, Aoi (Inspecție optică automată) detection, repair, testarea, and assembly.

Among the various processes in SMT manufacturing, three stand out as the most crucial: paste printing, SMT mounting, and reflow soldering.

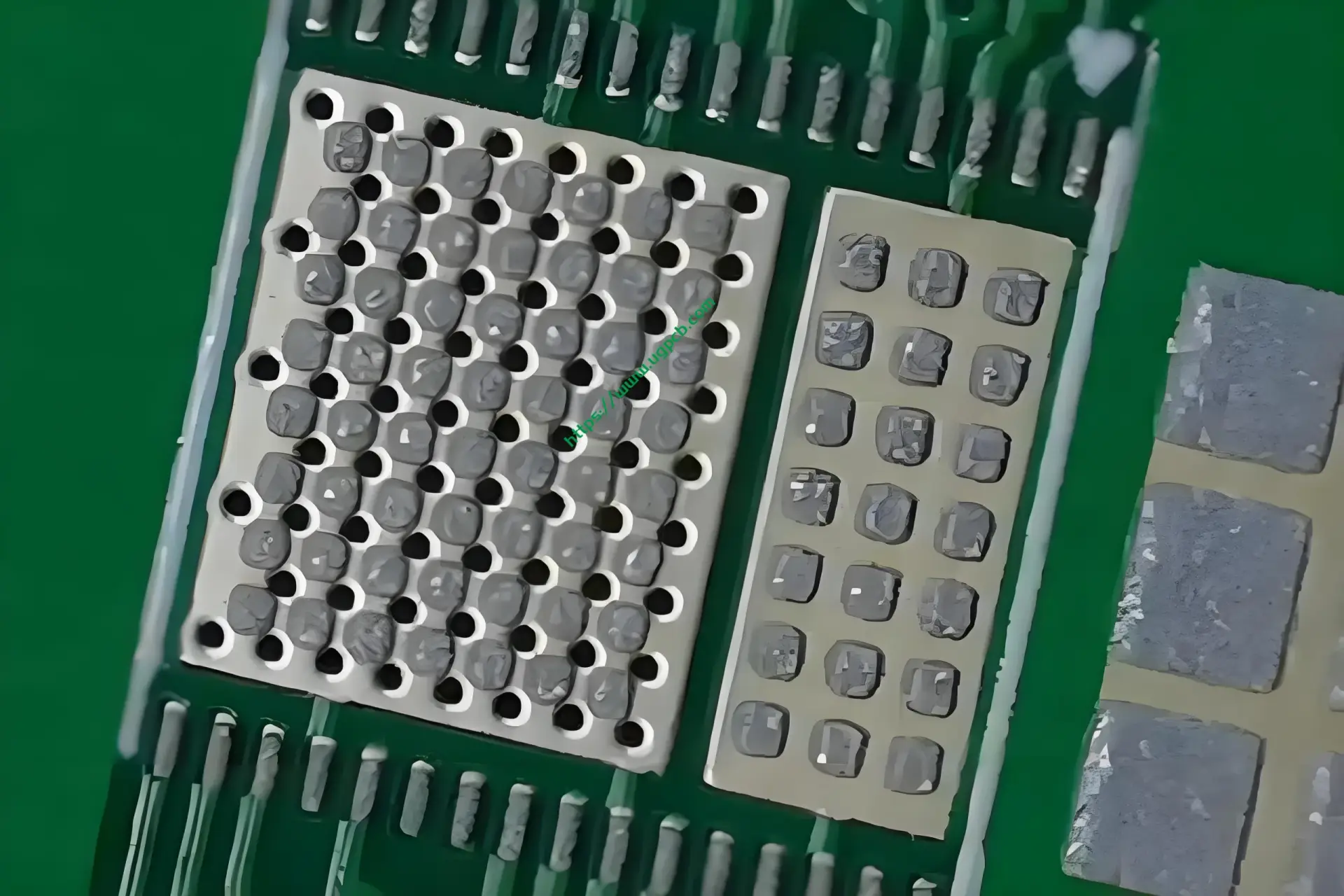

Paste Printing

Paste printing involves applying solder paste to the PCB (Placă de circuit tipărită). The equipment and tools used in this process include:

- Printing Machines: Fully automatic and semi-automatic printing machines.

- Solder Paste: A special material used to fix components onto the PCB.

- Stencil: Essentially a mold with hollowed-out positions corresponding to the soldering pads on the PCB, allowing the solder paste to seep through and coat the pads. It is a thin steel sheet fixed by a frame, commonly used in thicknesses of 0.10mm, varying based on the components and manufacturing process of different products. The stencil is made according to the paste mask file in the Gerber files provided by the R&D team or customer. This preparation is crucial before production as the stencil’s quality determines the quality of the mounted products. The importance of the stencil is especially evident in precision components, and different printing machines have slight variations in stencil aperture requirements. Based on personal experience, for products with precision components like 0.4-pitch BGA, it is recommended to have the stencil made by the production factory’s professionals, as there are no strict standards for the process. The details are best understood by the process engineers in the SMT factory.

The basic operation involves installing the stencil in the printing machine, adding solder paste to the stencil, placing the PCB on the machine’s track, scanning the PCB and stencil’s mark points with the machine’s camera, aligning them, raising the printing platform to fit the stencil, and then using a 45° inclined squeegee to scrape the solder paste across the stencil, transferring it to the soldering pads on the PCB. This completes the printing process. If there are no defects, it is perfect; if there are, the equipment engineer needs to make minor adjustments. Based on years of field process analysis, paste printing is the most critical of the three main processes in SMT manufacturing, as 70% of SMT defects are related to this step.

SMT Mounting

SMT mounting involves using a placement machine to mount components onto the printed PCB. The term “mounting” is used because the solder paste contains flux, which has a certain stickiness, allowing it to hold components before melting.

The principle of SMT mounting is both simple and complex. It is simple because it evolved from manual soldering, where components were placed on the circuit board with tweezers, while placement machines use vacuum suction heads to attach components to the PCB. It is complex because the actual mounting process is intricate, involving precise equipment. Technological advancements have transformed traditional through-hole components into surface-mount components, significantly increasing production efficiency and changing the entire industry’s supply chain.

The working principle of SMT involves creating a placement program using the Gerber files, coordinate files, BOM (Bill of Materials), and position diagram provided by the customer. The placement heads (suction nozzles), feeders, and tracks of the placement machine work together to complete the entire mounting process.

- Suction Nozzles: The placement head has 12 suction nozzles, each with a hollow center that uses vacuum suction to pick up components.

- Feeders: These are feed devices that, based on the placement program created by the placement machine programmer, are printed into a station list. Operators install components on the feeders according to the station list order. The feeders are arranged on the placement machine, powered on, and driven by gears to advance the component tape. The program instructs the specified suction nozzle to move to the designated position to pick up the component and place it at the specified coordinate.

Precautions:

- Different-sized components require different-sized suction nozzles and feeders.

- Since the suction nozzles use vacuum pickup, it is essential to ensure that the component surface is flat and does not leak vacuum during design and sample production. For special components like contact antennas or hollowed-out devices, suppliers may need to add “caps” or apply high-temperature adhesive tape to the surface.

- Avoid using bulk materials.

Reflow Soldering

After paste printing and mounting, the next step is reflow soldering. Once all components are mounted, the PCB is transported to the conveyor by the placement machine for manual inspection or pre-oven AOI inspection to check for any mounting defects. If there are no issues, the PCB can enter the reflow oven.

Many may not know what “reflow” means in reflow soldering. It does not refer to the solder paste flowing from one place to another. Reflow soldering comes from “Reflow Soldering,” where “reflow” means transforming granular solder paste into a liquid state and then solidifying it into an alloy. The reflow oven is like a “baking oven” with a conveyor belt resembling a bicycle chain. It is a rectangular oven that transports PCBs, heats and melts the solder paste, and solidifies the components onto the PCB’s soldering pads. The reflow oven has hot air devices divided into multiple temperature zones, gradually heating up. The process can be described using a curve with four key zones.

- Preheat Zone: Preheats the PCB and components, mainly referring to the heating effect of the first one to three heating zones of the reflow oven. Higher preheating achieves thermal equilibrium for the materials to be soldered, allowing the solder paste to become active, and components like flux to evaporate appropriately, paving the way for good soldering later.

- Soak Zone: Removes surface oxides and makes the solder paste active, with the solder paste in a semi-molten state, corresponding to the fifth, sixth, and seventh heating zones of the reflow oven.

- Reflow Zone: Also known as the soldering zone, it is the hottest area in the reflow oven, reaching the melting point of the solder paste, typically around 220°C for lead-free solder paste, lasting about 40 secunde.

- Cooling Zone: Slowly cools down from the melting point to around 50°C, forming alloy solder joints.

This completes the reflow process, which usually takes about six minutes.

Concluzie

This article provides an explanation and description of the three main processes of SMT manufacturing: printing, mounting, and reflow soldering. With this information, relevant personnel should have a deeper understanding of these crucial steps in SMT manufacturing.