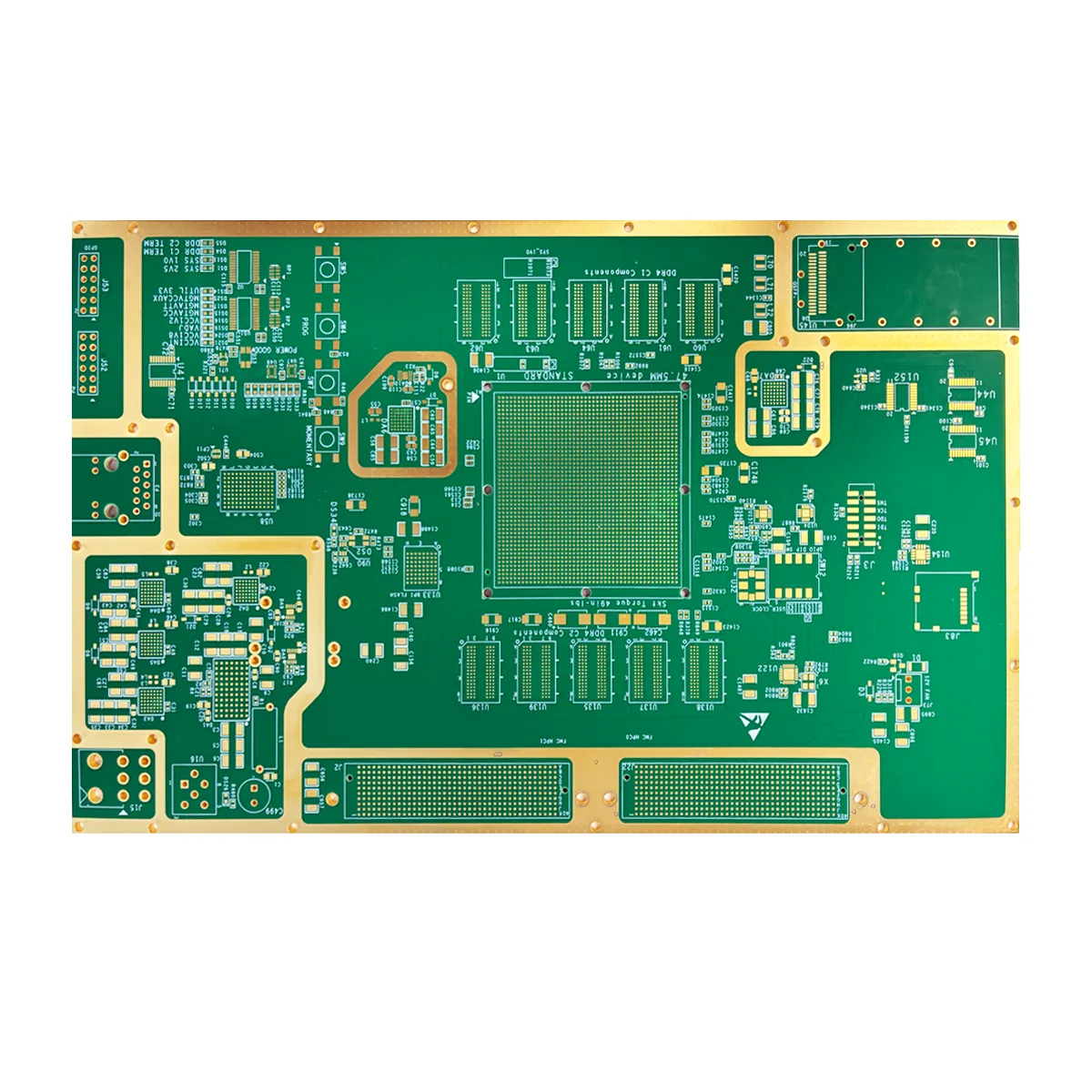

In the era of data-intensive and ultra-high-speed signal transmission, a Printed Circuit Board (PCB) is far more than a simple component carrier; it is the critical architecture defining system performance limits. For demanding applications like high-speed networking, artificial intelligence computing, and advanced test instrumentation, standard FR-4 materials fall short. UGPCB addresses this need with our advanced 22-layer multilayer PCB built on Panasonic Megtron-6 R-5775G laminate, engineered to meet challenges of high frequency, low loss, and complex interconnectivity.

1.UGPCB’s 22-Layer Megtron-6 High-Speed PCB Product Overview & Definiţie

This product is a 22-layer High-Density Interconnect (HDI) rigid printed circuit board. Its core advantage lies in the use of a premium-grade, de mare viteză, low-loss laminate—Panasonic’s Megtron-6 R-5775G. Combined with a robust 2.0mm board thickness and precision lamination technology, it creates a high-end interconnection platform capable of handling high-frequency signals above 10GHz with exceptional signal integrity and power integrity.

2. Critical Design Considerations

Designing such an advanced placă de circuite multistrat requires focus on:

-

Controlul impedanței: Precise calculation and control of single-ended and differential impedance to ensure consistent signal propagation within the Megtron-6 dielectric.

-

Optimizarea stivuirii: The intelligent arrangement of the 22 conductive layers (22Straturi)—including signal, power, and ground planes—is crucial for maximizing shielding and minimizing crosstalk in this high-layer count PCB.

-

Managementul termic: The 2.0mm board thickness and multilayer structure aid heat distribution. Cu toate acestea, strategic use of thermal vias remains essential for high-power IC areas.

-

High-Frequency Routing: Employing microstrip or stripline configurations, avoiding acute angle turns, and leveraging the low-profile copper foil of Megtron-6 to reduce losses from skin effect.

3. How It Works & Structura

O PCB’s primary function is to provide electrical connectivity and signal transmission between components via etched copper traces on an insulating substrate. Acest 22-layer PCB board structure resembles a precise “multi-layer sandwich”:

-

Inner Layers: Use H/HOZ (approximately 1/1 oz or 35µm) copper for core power, avioane la sol, and some internal signal routing.

-

Outer Layers: Use 1/1 oz copper for mounting primary components and routing critical signal traces.

-

Dielectric Layers: All insulating prepreg materials are Panasonic Megtron-6 R-5775G, whose low Dielectric Constant (DK) and Dissipation Factor (Df) ensure superior high-speed signal transmission.

-

Surface Finish: Electroless Nickel Immersion Gold (De acord) la 2 micro-inches (2u”). This provides a flat, solderable surface, excellent oxidation resistance, and good wire-bonding capability, ideal for high-density BGA packages and RF connectors.

4. Core Material: Panasonic Megtron-6 R-5775G

This is the heart of this advanced PCB material. Megtron-6 is Panasonic’s next-generation, de mare viteză, low-loss circuit board material series.

-

Key Performance: Features an extremely low Dielectric Constant (Dk~3.5) and ultra-low Dissipation Factor (Df~0.0015 @ 10GHz), significantly outperforming standard FR-4. Its high Glass Transition Temperature (TG) ensures superior thermal stability and dimensional consistency during high-temperature reflow soldering processes.

-

Application Fit: Optimized for high-speed digital signals (10Gbps+ to 56/112Gbps) and millimeter-wave RF applications.

| Articol | Metoda de testare | Stare | Unitate | Megtron6 R-5775(N) Pânză de sticlă DK joasă |

Megtron6 R-5775 Pânză de sticlă normală |

|

| Temp de tranziție din sticlă.(TG) | DSC | O | ° C. | 185 | 185 | |

| Tempora de descompunere termică.(TD) | TGA | O | ° C. | 410 | 410 | |

| Axa X CTE | A1 | IPC-TM-650 2.4.24 | O | PPM/° C. | 14-16 | 14-16 |

| CTE-axa y | 14-16 | 14-16 | ||||

| CTE Z-axa | A1 | IPC-TM-650 2.4.24 | O | 45 | 45 | |

| A2 | 260 | 260 | ||||

| T288(cu cupru) | IPC-TM-650 2.4.24.1 | O | min | >120 | >120 | |

| Constanta dielectrică(DK) | 12GHz | Tip echilibrat Resonator circular pe disc |

C-24/23/50 | - | 3.4 | 3.6 |

| Factor de disipare(Df) | 0.004 | 0.004 | ||||

| Absorbția apei | IPC-TM-650 2.6.2.1 | D-24/23 | % | 0.14 | 0.14 | |

| Modul de flexiune | Umple | Jis c 6481 | O | GPA | 18 | 19 |

| Coajă de rezistență* | 1Oz(35μm) | IPC-TM-650 2.4.8 | O | KN/m | 0.8 | 0.8 |

5. Caracteristici cheie & Performanţă

-

Ultra-Low Signal Loss: Megtron-6 material ensures maximum efficiency in high-frequency signal transmission with minimal attenuation.

-

Excellent Thermal & Dimensional Stability: High Tg value combined with a 2.0mm thick board suits high-temperature, high-power application environments.

-

High-Density Interconnect Capability: The 22-layer design provides abundant routing channels, supporting complex interconnections for large-scale chips (De ex., FPGAs, GPUs).

-

Precise Impedance & Layer-to-Layer Registration: Mature manufacturing processes guarantee consistent electrical performance across the PCB multistrat.

-

Superior Solderability & Bonding: The 2u” ENIG finish ensures highly reliable solder joints and is suitable for precision SMT assembly.

6. Scientific Classification & Aplicații primare

-

Scientific Classification:

-

By Layer Count: High Multilayer PCB (De obicei >10 straturi).

-

După Material: PCB de mare viteză / High-Frequency PCB / Low-Loss PCB.

-

Prin tehnologie: PCB HDI (Subject to specific design features like blind/buried vias).

-

By Rigidity: Rigid PCB.

-

-

Aplicații primare & Cazuri de utilizare:

-

High-Speed Networking Equipment: Core backplanes and motherboards for 400G/800G optical modules, high-end routers, and switches.

-

Advanced Computing & Storage: AI server boards, Calcul de înaltă performanță (HPC) clusters, enterprise SSD controller boards.

-

Aerospațial & Sisteme radar: RF front-ends and signal processing units for avionics communication and phased array radar systems.

-

Advanced Test & Measurement Instruments: Mainboards within high-speed oscilloscopes, spectrum analyzers, and signal generators.

-

7. Production Flow Overview

UGPCB adheres to a stringent PCB manufacturing process to ensure quality:

Material Cutting → Inner Layer Imaging → Lamination (22-Layer Alignment & Bonding) → Drilling → Hole Metallization → Outer Layer Imaging → Pattern Plating → Etching → Solder Mask Application → ENIG Surface Finish → Routing / Scoring → Electrical Testing → Final Inspection (AOL)

Every step is supported by high-precision equipment, with multiple quality control checkpoints integrated into the PCB fabrication process, ensuring this 22-layer Megtron-6 PCB meets the highest standards from design to delivery.

Don’t let base materials limit your innovative designs.

Whether you’re developing next-gen communication hardware or tackling frontier computing challenges, UGPCB 22-layer high-performance PCB solution is your reliable hardware foundation. We provide not just a product, but full-spectrum support from PCB design consultation to rapid prototyping and volume production.

Click to request a quote and receive expert technical documentation. Power your project with a superior core!