Изготовленная на заказ двухслойная жесткая печатная плата FR-4: СОГЛАШАТЬСЯ + Hard Gold Finish for High Reliability & Экономическая эффективность

Discover the industry “gold standard” for balanced performance and affordability. UGPCB’s 2-layer rigid FR-4 печатная плата, featuring TG150 high-temperature material and a dual ENIG + Hard Gold surface finish, delivers superior reliability for demanding applications.

я. Why Choose 2-Layer Rigid FR-4 PCB?

In the era of electronic miniaturization, спрос на высокая надежность, бюджетный, и compact design has made the 2-layer rigid PCB the “golden choice” for engineers and procurement managers. Unlike single-sided boards limited by routing space or expensive multi-layer boards, the 2-layer design strikes the perfect balance between performance and price.

UGPCB enhances this baseline by utilizing FR-4 TG150 heat-resistant material and a specialized Химическое никель, иммерсионное золото (СОГЛАШАТЬСЯ) + Твердое золото обработка поверхности. This combination significantly improves durability and solderability, making it suitable for a wider range of harsh environments.

II. Product Core Specifications (IPC-A-600 Compliant)

The following parameters ensure full compatibility with industry standards and optimal manufacturability (DFM).

| Параметр | Specification Details |

|---|---|

| Количество слоев | 2 Слои (Double-sided: Вершина & Bottom routing, FR-4 core substrate) |

| Толщина доски | 1.60мм (Standard industry thickness, balancing mechanical strength & космос) |

| Базовый материал | FR-4 TG150 (Epoxy resin glass cloth; Glass Transition Temp: 150°С; Excellent heat resistance) |

| Поверхностная отделка | ENIG 2u” + Hard Gold 30u” (Dual protection: Chemical immersion gold + Electroplated gold for wear resistance) |

| Медный вес | 1унция (35мкм) (Стандартная толщина, sufficient for most current carrying requirements) |

| Припаяя маска | Зеленый (Default; Черный, Синий, Красный, White available upon request) |

| Шелковик | White Epoxy Ink (Component identifiers, Logo) |

| Мин. Drill Hole | 0.3мм (12мил) |

| Мин. Ширина линии/пространство | 3мил / 3мил |

III. Product Definition: What is a 2-Layer Rigid PCB?

1. Определение

А Rigid PCB is a non-flexible printed circuit board composed of a substrate, copper foil traces, паяльная маска, and silkscreen. It establishes fixed electrical connections through drilling and etching processes.

А 2-Layer Rigid PCB (Double-Sided Board) is the foundational type of rigid PCB, featuring copper traces on both the top and bottom sides of the substrate. Electrical connections between layers are achieved via Plated Through Holes (Варенья).

2. Classification by Layer Count

- 1-Слой (Single-Sided): Circuits on one side only. Lowest cost but severe routing limitations.

- 2-Слои (Double-Sided): Circuits on both sides. Higher routing flexibility than single-sided; moderate cost. (UGPCB’s Specialty)

- Multi-Layer (4+ Слои): Three or more copper layers. Suitable for complex circuits but significantly higher cost.

UGPCB’s 2-layer offering represents the highest cost-performance ratio in the rigid PCB category.

IV. Design Guidelines for High Reliability

With limited routing space on 2-layer boards, придерживаясь МПК-2221 design standards is crucial for signal integrity and thermal management.

1. Power and Ground Layout

- Ground Planes: Use large copper pours for Ground (Гнездо) to minimize signal interference and EMI.

- Power Traces: Widen VCC traces to >20мил to reduce resistance and voltage drop.

- Spacing: Maintain a minimum 10mil clearance between power and ground to improve filtering.

2. Signal Routing

- Differential Pairs: For high-frequency signals (USB, HDMI), use differential routing to reduce electromagnetic radiation.

- 3W Rule: Maintain a spacing of ≥3x the trace width between signal lines to avoid crosstalk.

- Return Paths: Avoid signal traces crossing splits in the ground plane to prevent signal reflection.

3. Via Design

- Размер отверстия: Minimize via diameter (например, 0.3мм) to save routing space.

- Via Tenting: Use solder mask to cover vias to prevent solder paste wicking during soldering.

- Высокая частота: Use through-hole vias (standard for 2-layer) to minimize parasitic capacitance compared to blind/buried vias.

В. Operating Principle: How PCBs Work

The core function of a PCB is to connect electronic components (чипсы, резисторы, конденсаторы) via copper traces to achieve predetermined electrical functions.

- Пример: In a smartphone charging board, the PCB routes power from the USB interface to the charging management chip, distributes it to the battery, and feeds battery level data back to the system via signal lines.

- While the principle is identical to многослойные платы, 2-layer boards require meticulous layout planning to ensure Целостность сигнала (И) within limited space.

VI. Материал & Производительность: Why FR-4 TG150?

1. Базовый материал: FR-4 TG150

ФР-4 (Flame Retardant 4) is the industry standard for epoxy resin glass cloth substrates.

- High Mechanical Strength: Reinforced by glass cloth, resisting bending and breakage.

- Тепловая стабильность: TG150 (Glass Transition Temperature 150°C) ensures stability in high-temperature environments (industrial workshops, automotive engine compartments).

- Электрические свойства: Диэлектрическая проницаемость (Дк) 4.2-4.5, Коэффициент рассеяния (Дф) 0.02, making it suitable for high-frequency signal transmission.

- Химическая устойчивость: Resists corrosion from solder and flux, extending service life.

2. Поверхностная отделка: ENIG 2u” + Hard Gold 30u”

Surface finish acts as the PCB’s “protective shield.” UGPCB combines two finishes for maximum benefit:

- СОГЛАШАТЬСЯ (Химическое никель, иммерсионное золото): А 2u” (0.05мкм) gold layer deposited chemically. Offers excellent planarity and solderability, ideal for fine-pitch components (например, 0.5mm pitch chips).

- Твердое золото (Electrolytic Gold): A thick 30u” (0.76мкм) gold layer plated electrically. Provides superior wear resistance and conductivity, perfect for frequent plug-in/unplug cycles (USB ports, SD card slots).

Comparison: This combination outperforms HASL (Выравнивание припоя горячего воздуха) and standard OSP (Органическая припаяя консервант) in high-reliability applications like промышленный контроль и автомобильная электроника.

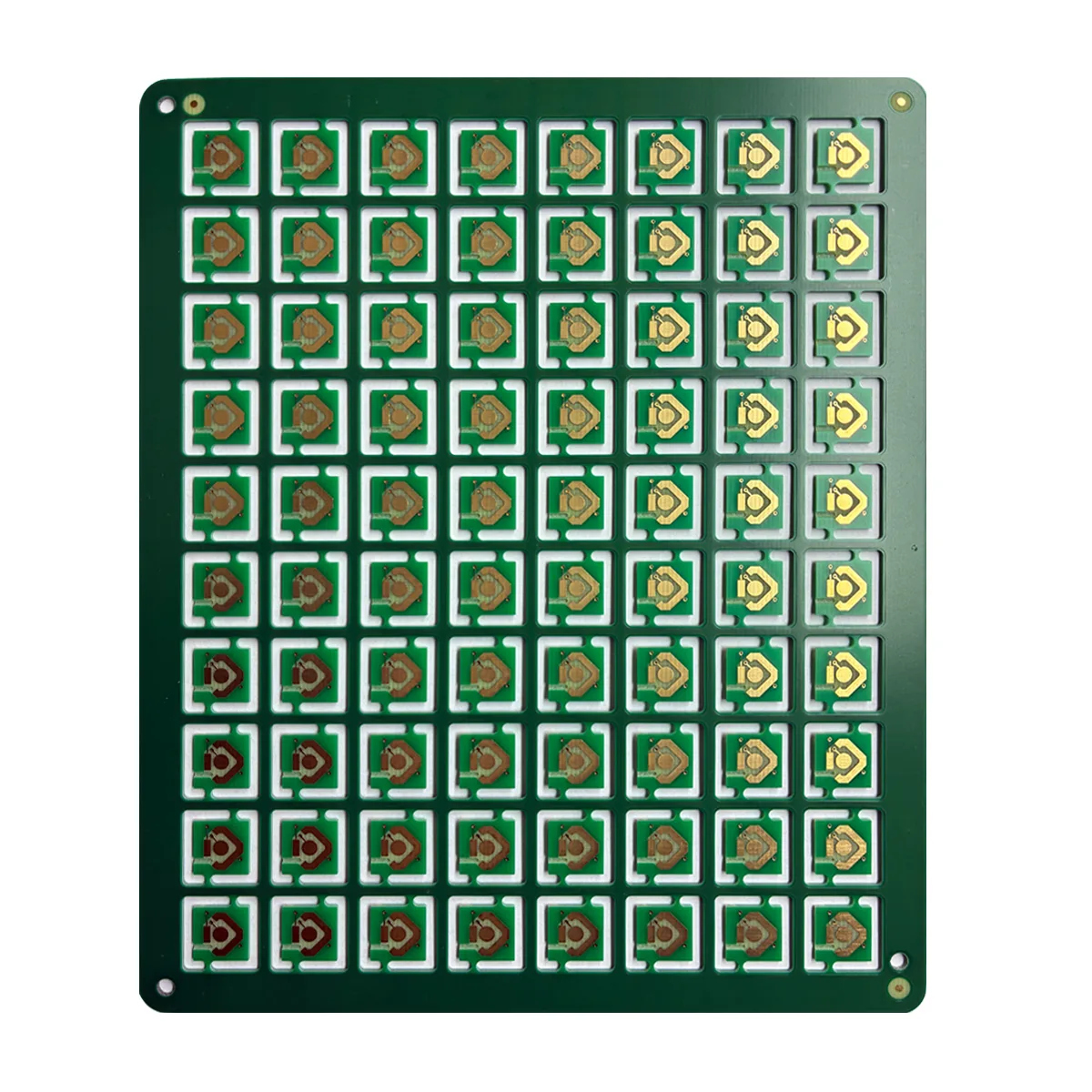

VII. Структура & Функции: Panelization Advantages

This PCB utilizes Matrix Panelization, where multiple individual PCBs (например, 10×10 array) are arranged on a larger production panel connected by Webs (Tabs).

Advantages of Panelization:

- Production Efficiency: Multiple PCBs produced simultaneously, reducing machine setup time.

- Снижение затрат: Minimizes scrap material and maximizes material utilization.

- Assembly Ease: Webs can be separated via routing or V-Cut (V-Scoring) without damaging individual boards.

Additional Product Features:

- Высокая надежность: FR-4 TG150 + ENIG/Hard Gold withstands harsh environments (high temp, влажность, вибрация).

- Бюджетный: Mature 2-layer process is 30%-50% дешевле than multi-layer boards.

- Customization: Supports min. 0.1mm hole size, мин. 3Мил трасса/пространство, and various finishes (Погружение серебро, ОСП, и т. д.).

- Eco-Friendly: Соответствует Rohs и ДОСТИГАТЬ стандарты; lead-free soldering ready for global export.

VIII. Производственный процесс: Strict IPC-A-600 & IPC-6012 Control

UGPCB’s workflow adheres strictly to IPC-A-600 (Quality Standard) и МПК-6012 (Performance Specification for Rigid PCBs).

- Резка: Shearing FR-4 laminate to required dimensions (например, 18″x24″).

- Бурение: CNC drilling for component holes (0.3мм) и переходные отверстия (0.2мм).

- Electroless Copper: Chemical deposition of 1-2μm copper for interlayer connectivity.

- Image Transfer: Applying photoresist, exposing, and developing to transfer circuit patterns.

- Офорт: Removing excess copper to form final traces.

- Припаяя маска: Coating with green solder mask ink, exposing, and curing to protect circuits.

- Поверхностная отделка: СОГЛАШАТЬСЯ (2u”) + Твердое золото (30u”) plating for solderability.

- Шелковик: Printing component designators (Р1, C2) and logos.

- Electrical Test: Тест летающего зонда to check continuity and isolation (no shorts/opens).

- Routing/V-Cut: Separating individual PCBs from the panel and chamfering edges.

- Заключительная проверка: АОИ (Автоматическая оптическая проверка) for scratches, окисление, dimensional accuracy, and reliability tests (Thermal Shock, Vibration).

IX. Сценарии приложения

Thanks to its high reliability and cost-effectiveness, this PCB is widely used in:

- Бытовая электроника

- Mobile/Tablets: Charging boards, силовые модули, keypads.

- Носимые устройства: Smartwatch motherboards, fitness tracker sensors.

- Home Appliances: AC control boards, washing machine displays.

- Промышленный контроль

- PLC Modules: I/O boards, communication modules.

- Датчики: Signal processing for temp/pressure sensors.

- Robotics: Servo motor control, encoder interfaces.

- Автомобильная электроника

- Infotainment: Navigation mainboards, audio controls.

- Системы безопасности: Reverse radar control, TPMS (Tire Pressure Monitoring).

- EVs: Charging pile control, Бит (Battery Management System) auxiliary boards.

- Медицинские устройства

- Portable Diagnostics: Glucose meters, sphygmomanometers.

- Monitoring: ECG, pulse oximeter signal boards.

- Surgical: Control boards for minimally invasive instruments.

- Other Fields

- Телеком: Router/Switch interface cards.

- Аэрокосмическая промышленность: Drone flight controllers, satellite comms.

- Умный дом: Smart locks, smart lighting controls.

Х. Почему выбирают UGPCB?

As a professional PCB manufacturer with over 10 years of experience, UGPCB serves 1000+ clients globally.

- Advanced Equipment: Japanese Mitsubishi drills, German LPKF exposure machines, US Test Research flying probe testers.

- Strict Quality: Сертифицировано с ISO9001, ISO14001, and IATF16949 (Автомобильная промышленность).

- Fast Turnaround: 24-hour lead time for prototypes; 3-5 days for volume production.

- Free Services: DFM (Дизайн для производства) Check, free quotes, and free sample testing (for first-time orders).

XI. Request a Quote: Accelerate Your Time-to-Market

If you need 2-layer rigid FR-4 PCBs or have questions about ENIG+Hard Gold или panelization, contact UGPCB today!

- ✅ Free DFM Review: Optimize your design to prevent manufacturing defects.

- ✅ Free Sample Testing: Verify performance before mass production.

- ✅ Competitive Pricing: Cost-effective solutions based on quantity and specs.

- ✅ Быстрая доставка: Prototypes in 24h, Mass production in 3-5 дни.

Summary

UGPCB 2-Layer Rigid FR-4 PCB, с участием FR-4 TG150 base material и СОГЛАШАТЬСЯ + Hard Gold surface finish, is the premier choice for applications demanding высокая надежность и бюджетный. Whether you are a consumer electronics manufacturer or an automotive engineer, we provide customized solutions that meet IPC-A-600 standards.

Contact us now to start your project and seize market opportunities!