UGPCB: Your One-Stop PCBA Solutions Expert – Redefining Electronics Manufacturing Standards with Superior Technology and Precision Quality Control

ภาพรวม: UGPCB’s Comprehensive PCBA Capabilities and Industry Positioning

According to IPC market research data, the global PCBA market size is projected to reach USD 102 billion by the end of 2025, with a Compound Annual Growth Rate (cagr) ของ 5.2%. In this rapidly growing market, UGPCB has secured a significant position through its professional technical expertise and customer-oriented service model. This is particularly evident in high-reliability sectors such as industrial control, อุปกรณ์การแพทย์, อุปกรณ์อิเล็กทรอนิกส์ยานยนต์, and communication technology, where the company excels.

Core Technical Capabilities in PCBA at UGPCB

เทคโนโลยี Mount Surface (SMT) and Through-Hole Technology (tht)

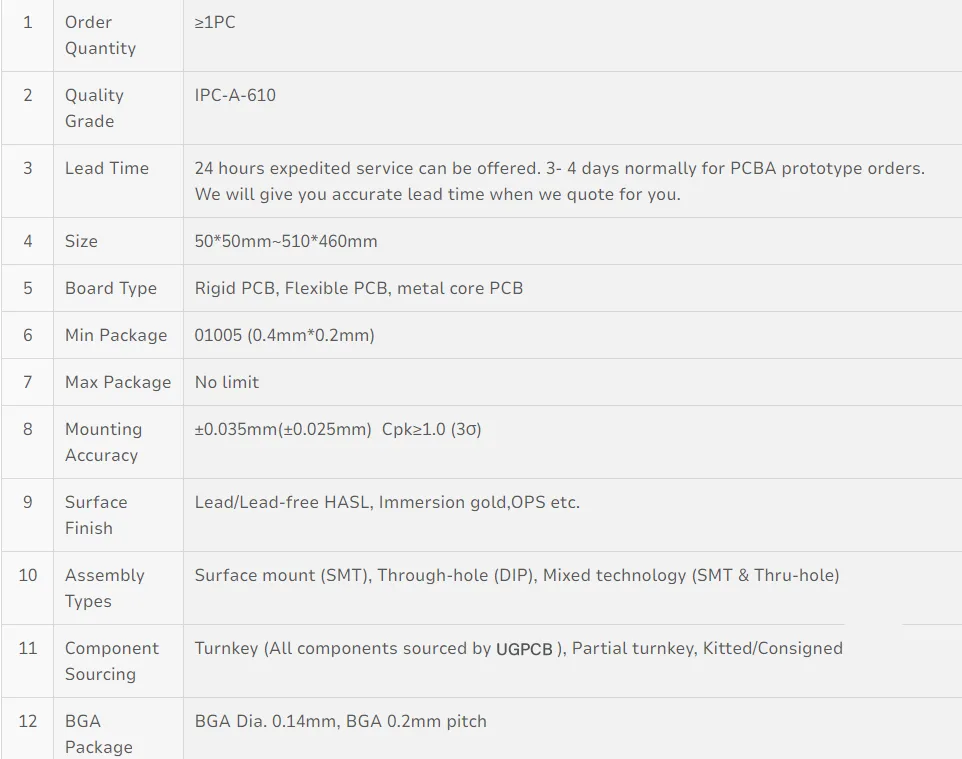

UGPCB operates advanced high-precision SMT production lines capable of handling components ranging from tiny 0201 chips (0.6mm x 0.3mm) to large BGAs (45mm x 45mm), achieving a placement accuracy of ±25μm @3σ (based on IPC-9850 standards). Our production lines are equipped with nitrogen reflow soldering systems that maintain oxygen content below 1000ppm, significantly improving soldering quality and reducing defects like cold joints and oxidation.

Solder quality is evaluated based on the IPC-A-610 standard using the formula:

Qs = (Na / Nt) × 100%

ที่ไหน Qs represents the solder yield, Na is the number of accepted solder joints, และ Nt is the total number of solder joints. UGPCB consistently maintains a typical solder yield above 99.95%, substantially higher than the industry average of 99.8%.

การเชื่อมต่อระหว่างกันที่มีความหนาแน่นสูง (HDI) Board Assembly Technology

As electronic products trend towards miniaturization and increased functionality, เอชดีไอ พีซีบี assembly has become a critical industry technology. UGPCB possesses extensive experience in บอร์ด HDI การผลิต, handling complex structures like blind and buried vias, microvias (minimum aperture of 0.1mm), and sequential lamination processes. Our HDI board assembly yield is 15-20% higher than the industry average, a result of precision equipment and strict adherence to the IPC-2226 standard.

Comprehensive Quality Assurance System: From Raw Materials to Finished Products

Multi-Tier Inspection Strategy

UGPCB implements a full-range quality inspection system to ensure every พีซีบี product meets the highest quality standards:

-

การควบคุมคุณภาพที่เข้ามา (IQC): XRF testing on all components for RoHS compliance and digital microscope inspection for device appearance and pin condition.

-

การควบคุมคุณภาพในกระบวนการ (ไอพีคิวซี): Real-time monitoring systems on production lines with 5ms response times for immediate detection and correction of process deviations.

-

การตรวจสอบด้วยแสงอัตโนมัติ (Aoi): Utilization of 3D AOI systems with a detection accuracy of 15μm to identify common defects like solder bridging, component misplacement, missing parts, and polarity errors.

-

X-Ray Inspection: 100% รังสีเอกซ์ inspection for hidden solder joints (เช่น, BGA, qfn) to ensure the integrity and quality of bottom-termination connections.

-

Functional Circuit Test (FCT) and In-Circuit Test (ไอซีที): Design of custom test solutions based on client requirements, covering voltage/current tests, signal integrity verification, and functional validation.

Reliability Testing and Validation

UGPCB’s reliability testing laboratory is equipped with advanced equipment to perform a series of Environmental Stress Screening (ESS) and life tests:

-

Thermal Stress Testing: Temperature cycling tests from -55°C to +125°C based on IPC-TM-650 2.6.7.

-

Vibration and Mechanical Shock Testing: Random vibration and mechanical shock tests according to MIL-STD-883, วิธี 2007.

-

Microsection Analysis: Cross-sectional analysis of solder joints using metallurgical microscopes to evaluate soldering quality and interface integrity.

-

Impedance Control Testing: Ensuring high-frequency signal integrity, controlling deviation within ±10% (based on IPC-2141).

One-Stop Solution: From Concept to Finished Product

ออกแบบเพื่อการผลิต (DFM) บริการ

UGPCB offers professional Design for Manufacturability (DFM) analysis services, engaging early in the design process to help clients optimize their designs for higher production yields and lower costs. Our engineering team uses advanced simulation software to analyze PCB designs and identify potential manufacturing issues, รวมทั้ง:

-

Component layout rationality analysis

-

Thermal management optimization

-

Signal integrity pre-analysis

-

Assembly difficulty assessment and improvement suggestions

Statistics show that early DFM analysis can reduce later engineering changes by up to 70%, shorten product development cycles by 30-40%, and improve first-pass yield by 15-25%.

Component Sourcing and Supply Chain Management

As a one-stop PCBA service provider, UGPCB offers comprehensive services including PCB design, การสร้างต้นแบบ, การผลิต, การจัดหาส่วนประกอบ, and PCB assembly. With a dedicated procurement team of over 20 specialists and direct partnerships with more than 6000 authorized distributors and original manufacturers, our supply chain management system ensures:

-

100% Genuine Guarantee: All components are sourced from original manufacturers or authorized distributors, with complete traceability documentation.

-

การเพิ่มประสิทธิภาพต้นทุน: Help clients reduce BOM costs by 10-30% through volume purchasing and alternative component suggestions.

-

Shortage Mitigation: Maintain safety stock and an alternative component database to effectively counter market shortage risks.

Flexible Production and Rapid Response Capability

UGPCB specializes in low to medium-volume production, making it ideally suited for prototype development, small-batch trial production, and specialized equipment manufacturing. เราเสนอ:

-

No Minimum Order Quantity (MOQ) requirement, supporting single-board production.

-

Fast Turnaround Times: Standard PCBA orders in 5-7 วัน, with expedited services available within 48 ชั่วโมง.

-

Flexible Production Scheduling: Support for multi-variety, small-batch mixed production models.

Specialized Technical Areas and Application Industries

Special PCB Manufacturing Capabilities

UGPCB not only provides standard FR-4 PCB production but also excels in various special processes and materials:

-

Metal Core PCBs: Aluminum and copper core boards with thermal conductivity up to 8.0 w/(M · K), ideal for high-power LED lighting and power modules.

-

Flexible Circuits (FPC) and Rigid-Flex Boards: Minimum trace width/spacing of 2.5/2.5 MIL, bend radius less than 3mm, suitable for wearable and mobile devices.

-

High-Frequency PCBs: Use of high-frequency materials like Rogers and Taconic, with Dk values ranging from 2.2 ถึง 10.2, for 5G communication and radar systems.

-

Heavy Copper PCBs: Copper thickness up to 20 ออนซ์, designed for high-current applications such as power systems and motor drives.

โซลูชั่นแอปพลิเคชันอุตสาหกรรม

UGPCB’s PCBA services are widely applied across multiple high-demand industries:

-

อุปกรณ์การแพทย์: Compliant with ISO 13485, producing PCBA for patient monitoring, diagnostic equipment, and portable medical devices.

-

อุปกรณ์อิเล็กทรอนิกส์ยานยนต์: Adhering to IATF 16949, providing PCBA solutions for vehicle control systems, เซ็นเซอร์, and infotainment systems.

-

การควบคุมอุตสาหกรรม: Manufacturing high-reliability PCBA for PLCs, industrial computers, and automation equipment, ensuring stable operation in harsh environments.

-

อุปกรณ์สื่อสาร: Specializing in high-frequency, high-speed PCBA for 5G base stations, network switching equipment, and fiber-optic communication devices.

Environmental and Electrostatic Discharge (ESD) Protection Systems

RoHS Compliance and Eco-Friendly Manufacturing

UGPCB fully complies with EU RoHS directives and REACH regulations. All production processes and materials meet environmental requirements:

-

Use of Lead-Free Solder: SAC305 (Sn96.5/Ag3.0/Cu0.5) and other lead-free alloys.

-

Complete Material Declarations: Ensure products meet environmental regulations globally.

-

Waste Management System: Chemical waste from production is handled according to ISO 14001 มาตรฐาน.

การปล่อยไฟฟ้าสถิต (ESD) การป้องกัน

UGPCB implements a comprehensive ESD protection system based on ANSI/ESD S20.20 standards:

-

สำนักงานปกป้องสิ่งแวดล้อม (ESD Protected Area): All work areas feature anti-static flooring, workstations, and ionization systems.

-

Personnel Protection: All operators are required to wear ESD garments, wrist straps, and footwear.

-

Equipment Grounding: All equipment grounding resistance is maintained within the safe range of 1-10MΩ.

-

การตรวจสอบแบบเรียลไทม์: Continuous monitoring systems ensure ESD protective measures remain effective at all times.

Packaging and Logistics: The Final Guarantee for Safe Delivery

UGPCB employs a multi-layer protective packaging system to safeguard products against mechanical damage, moisture, and electrostatic hazards during transportation:

-

Inner Packaging: Anti-static foam, anti-static bags (surface resistivity 10^5-10^11 Ω/sq).

-

Middle Protection: Custom foam padding, partitions, and protective corner pieces.

-

Outer Packaging: Double-walled corrugated cartons, wooden crates, and waterproof film.

-

Transport Monitoring: Optional temperature/humidity loggers and shock indicators.

Our logistics partners include international couriers like DHL, FedEx, and UPS, ensuring fast and reliable delivery worldwide.

How to Start Your PCBA Project

Initiating a partnership with UGPCB is straightforward. Simply provide the following documents and information:

-

ไฟล์ Gerber: PCB design files including all layers (RS-274X format recommended).

-

ใบเรียกเก็บเงิน (ระเบิด): Including manufacturer part numbers, package types, reference designators, and quantities.

-

Assembly Drawing: Detailed drawing indicating component placement and orientation.

-

Test Requirements: Specific test procedures and acceptance criteria (ถ้ามี).

Our engineering team will provide a preliminary DFM analysis report and a transparent quotation, clearly listing all cost components, ภายใน 4 ชั่วโมง. For new clients, we offer free sample services and discounts on first orders.

บทสรุป: เลือก ugpcb, Choose a Reliable Partner

จบด้วย 10 years of professional experience, advanced technical equipment, and a strict quality management system, UGPCB has become the preferred PCB and PCBA partner for numerous global enterprises and R&D institutions. We deeply understand the importance of high-quality PCB assembly for product success and consistently adhere to a customer-centric service philosophy, offering end-to-end solutions from design support to final delivery.

Whether you are a startup needing prototype development or an established enterprise requiring small to medium-volume production, UGPCB provides professional, มีประสิทธิภาพ, and reliable PCBA services. Click the online chat icon in the bottom right corner of the page to contact our technical team and learn more about optimizing your electronics manufacturing project.

You can also send your inquiry to sales@UGPCB.com for a professional quotation and technical advice!