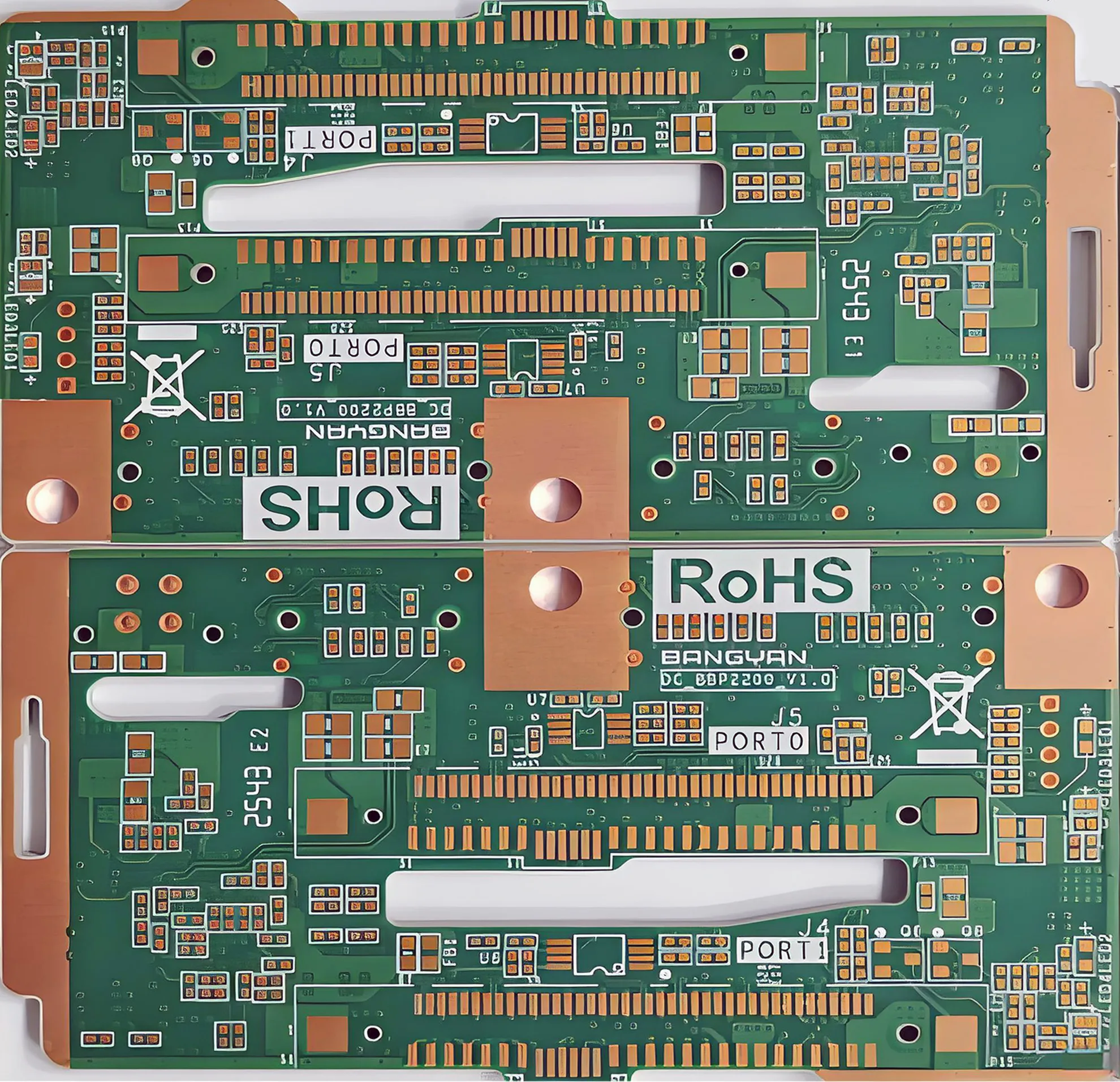

Professional Product Overview: The 12-Layer High-Speed, High-Density PCB

In the era of high-speed data transmission and complex system integration, conventional printed circuit boards (PCBS) fall short of meeting the performance demands of advanced electronics. ที่ 12-layer high-speed, high-density PCB is the engineered solution. Featuring up to 12 precisely aligned conductive layers, it enables intricate interconnections and efficient signal transmission within a compact footprint, serving as the “central nervous system” for high-end networking gear, data center servers, คอมพิวเตอร์ประสิทธิภาพสูง (HPC), and AI hardware.

As an expert ผู้ผลิต PCB และ PCB supplier, UGPCB leverages advanced processes to deliver reliable 12-ชั้น บอร์ด PCB การผลิต, ensuring your products maintain a competitive performance edge.

In-Depth Parameter Analysis: The Foundation of Performance

The capability of a high-quality multilayer printed circuit board is defined by its specifications. Below is an analysis of this product’s core parameters:

-

จำนวนเลเยอร์ & Stack-up: 12 ชั้น. นี้ multilayer PCB design offers superior signal integrity (และ), ความสมบูรณ์ของพลังงาน (PI), and EMC performance compared to boards with fewer layers. It allows for dedicated power and ground planes, providing clear return paths for high-speed signals.

-

ความหนาของบอร์ด & Tolerance: 2.4mm ±10%. This robust thickness offers excellent mechanical strength for backplanes and large-form-factor applications, ensuring reliability during mating and installation. The tight tolerance guarantees consistency in assembly.

-

Finished Copper Weight: Unique distribution:

1/1/1/1/1/2/2/1/1/1/1/1 oz. This indicates that the inner layers (L6 & L7) utilize 2oz heavy copper, designed specifically for high-current power delivery. The outer and other signal layers use 1oz copper, optimized for fine-line etching. This hybrid construction is a hallmark of high-reliability การผลิต PCB. -

Critical Process Capabilities:

-

Minimum Drilled Hole Size: 0.2มม. Supports high-density BGA fan-out, enhancing routing flexibility.

-

Minimum Line Width/Space: 0.076มม / 0.09มม (3MIL / 3.5MIL). บรรลุผลสำเร็จ การเชื่อมต่อระหว่างกันที่มีความหนาแน่นสูง (HDI)-level routing, essential for high-speed signal propagation.

-

-

พื้นผิวเสร็จสิ้น: โอป (สารกันบูด). Compatible with both leaded and lead-free soldering, it protects copper pads from oxidation, offers excellent surface planarity, and is cost-effective—ideal for boards with dense SMT ส่วนประกอบ.

วัสดุหลัก & Key Technologies: Enabling Superior Signal Integrity

-

High-Performance Laminate: Utilizes นันย่า NY6300S high-speed laminate. Its high glass transition temperature (ทีจี >150องศาเซลเซียส) ensures dimensional stability and reliability during high-temperature reflow soldering. Its optimized dielectric constant (ดีเค) and dissipation factor (ฟ) significantly reduce signal loss at high frequencies, forming the material foundation for PCB ความถี่สูง.

-

Advanced Copper Foil: Employs มูลนิธิฯ (Reverse Treated Foil) ทองแดง. Compared to standard electrodeposited (เอ็ด) foil, RTF foil features a smoother, low-profile surface on the treated side. This reduces signal loss due to the “skin effect” at high frequencies, critically enhancing the performance of differential signals exceeding 10 Gbps.

-

Critical Process: Controlled-Depth Drilling (การขุดเจาะหลัง): In 12-layer or higher PCB หลายชั้น, the unused portion (stub) of a through-hole via can cause significant signal reflection, degrading integrity. ที่ back drilling process precisely removes this non-functional via stub, eliminating its negative impact—a key technology for high-speed multilayer PCB ผลงาน.

Production Flow & การประกันคุณภาพ

UGPCB 12-กระบวนการผลิต PCB ชั้น strictly adheres to มาตรฐาน IPC and includes ออกแบบเพื่อการผลิต (DFM) ทบทวน, inner layer imaging, การเคลือบ, การขุดเจาะ (including back drilling), ชุบ, outer layer imaging, solder mask application, พื้นผิวเสร็จสิ้น (โอป), การกำหนดเส้นทาง, การทดสอบทางไฟฟ้า, and final inspection. Each stage is supported by precision measurement equipment (Aoi, Impedance Testing, Flying Probe Test), ensuring every แผงวงจร delivered meets design specifications and our high-quality standards.

การใช้งานทั่วไป & Product Classification

This high-performance บอร์ด PCB is designed for demanding electrical environments and complex systems, primarily used in:

-

High-End Network & อุปกรณ์สื่อสาร: Core motherboards for 400G/800G optical modules, high-end routers, and switches.

-

Data Center & คลาวด์คอมพิวติ้ง: Server motherboards, accelerator cards, storage backplanes.

-

High-Performance Computing: Workstation motherboards, GPU computing cards, AI accelerator hardware.

-

Advanced Test & Measurement Instruments: Internal boards for instruments processing very high-frequency signals.

Scientific Product Classification:

-

โดยการนับเลเยอร์: PCB หลายชั้น (>8 ชั้น)

-

By Technology Type: High-Speed/High-Frequency PCB, เอชดีไอ พีซีบี, Heavy Copper PCB (partial)

-

โดยการสมัคร: Telecom Infrastructure PCB, Data Center/Server PCB

Why Choose UGPCB for Your 12-Layer High-Speed PCB?

-

ความเชี่ยวชาญด้านเทคนิค: Proven mastery of back drilling และ RTF copper foil application to tackle high-speed design challenges.

-

การผลิตที่แม่นยำ: Capable of 3/3.5 mil line/space, meeting stringent high-density interconnect requirements.

-

Material Integrity: Core use of reputable high-speed laminates like Nanya NY6300S ensures foundational performance.

-

สนับสนุนการออกแบบ: Expert การออกแบบ PCB และ DFM review services to de-risk your project from the start.

-

Consistent Quality: A fully controlled การผลิต PCB and inspection system delivers reliable products you can trust.

Ready to elevate your hardware? Contact UGPCB’s engineers for a free PCB quote และ การวิเคราะห์ DFM on your next 12-layer high-speed board project.