High-Thermal FR-4 Single-Side Aluminum Base PCB Product Overview & คำนิยาม

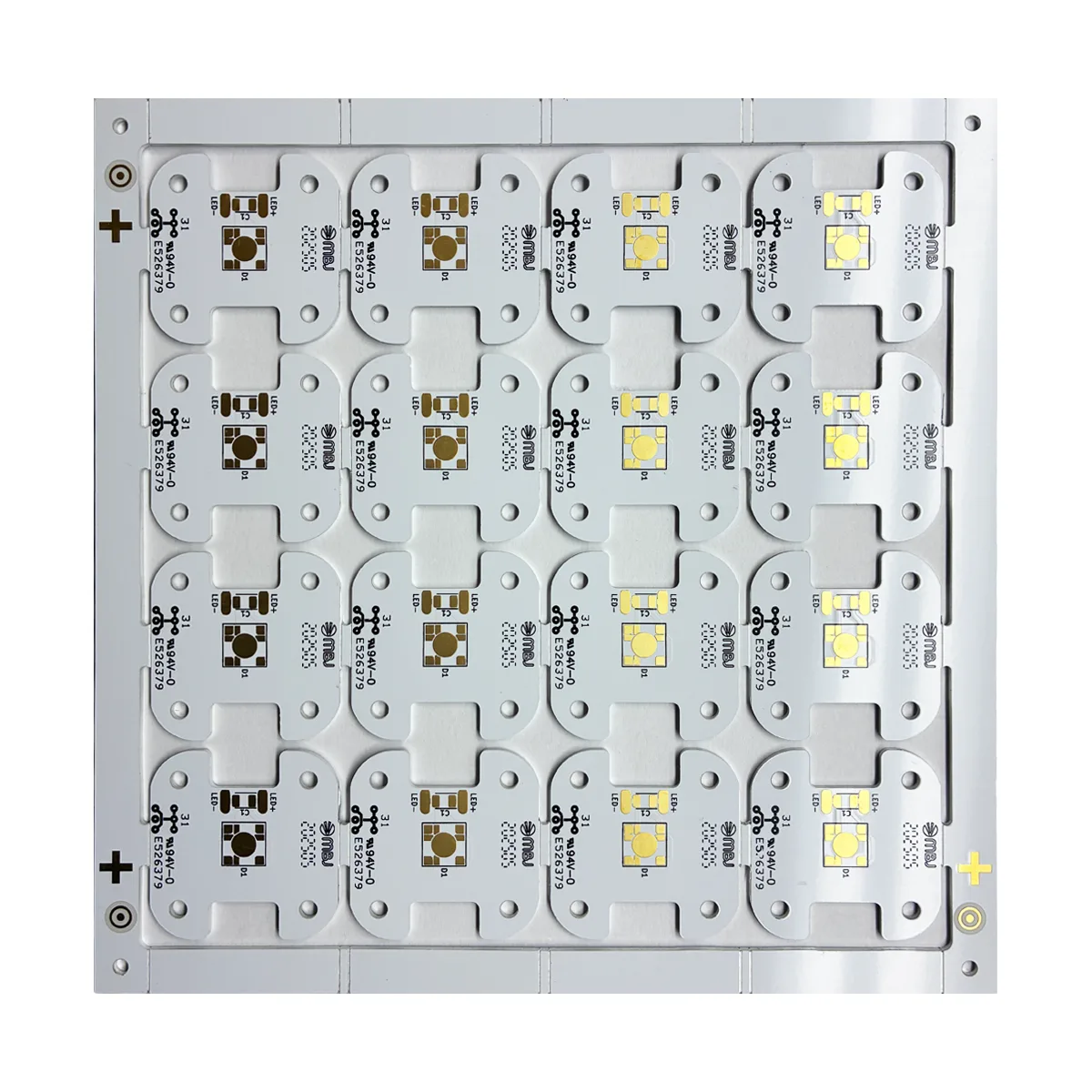

In today’s high-power, high-density electronic devices, ที่ thermal management capability of a แผงวงจรพิมพ์ (พีซีบี) is critical for product reliability and longevity. UGPCB 1.6mm Single-Side Aluminum Base PCB (1 Layer Aluminum Core PCB) is an innovative solution that combines a high-Tg FR-4 laminate with an integrated thermal management structure. This design achieves an optimal balance between the excellent electrical properties of FR-4, ความคุ้มค่า, and heat dissipation performance comparable to dedicated Metal Core PCBs (MCPCBs). นี้ Thermal Management PCB is specifically engineered to solve cooling challenges in applications like LED lighting and power conversion modules.

Core Specifications & การจำแนกประเภททางเทคนิค

-

จำนวนเลเยอร์: 1 ชั้น (Single-Sided PCB)

-

ความหนาของบอร์ด: 1.6มม (มาตรฐาน, robust)

-

Base Laminate Material: FR-4, อุณหภูมิการเปลี่ยนแก้ว (ทีจี) ≥ 150°C (High Tg FR-4 PCB)

-

Thermal Structure: Integrated Aluminum Base Layer/Block (Metal Core PCB)

-

พื้นผิวเสร็จสิ้น: ทองคำแช่นิเกิลแบบไม่ใช้ไฟฟ้า (เห็นด้วย), 2 micro-inches Gold Thickness (approx. 0.05µm)

-

Legend/Silkscreen: White LPI Solder Mask, Black Text (High contrast for clear identification)

Scientific Classification:

-

โดยการนับเลเยอร์: Single-Sided Board.

-

By Substrate Type: Rigid Composite Metal Core Printed Circuit Board.

-

By Thermal Performance: High Thermal Conductivity PCB.

-

By Primary Application: High-Power LED Heat Sink Board, Power Supply Cooling Board.

แนวทางการออกแบบ & Operating Principle

ข้อควรพิจารณาในการออกแบบที่สำคัญ:

-

Heat Source Placement: High-heat-dissipation components (เช่น, LED chips, power MOSFETs) should be placed on pads directly connected to or in close proximity to the aluminum base thermal pad area to ensure the shortest thermal path.

-

Electrical Isolation: Although it features a metal base, electrical isolation between the circuit and the metal core is maintained through the FR-4 dielectric layer และ thermally conductive insulating layer. Design must ensure the required insulation withstand voltage (โดยทั่วไป >2KV) is met.

-

Copper Weight Selection: Choose appropriate copper foil thickness (standard 1oz/2oz) based on current-carrying requirements. Widen traces or use copper pours for high-current paths.

-

ENIG Finish Advantage: ที่ 2u” ENIG surface finish provides excellent flatness and solderability, ideal for fine-pitch SMT components and connectors subject to repeated mating cycles.

Operating Principle:

The core functionality of this บอร์ด PCB is to utilize the high thermal conductivity of aluminum (approx. 200 w/m · k) to rapidly absorb and spread heat generated by components on the circuit layer. The heat is then dissipated into the environment via the chassis or an external heatsink attached to the board. The structure acts as a “thermal highway,” conducting heat from localized hotspots across the entire metal base area, significantly lowering junction temperatures and enhancing system stability.

วัสดุ, การก่อสร้าง & คุณสมบัติที่สำคัญ

วัสดุที่ใช้:

-

Circuit Layer: Electro-Deposited (เอ็ด) ฟอยล์ทองแดง

-

Dielectric/Insulating Layer: High-Tg FR-4 Epoxy Glass Laminate (ทีจี 150)

-

Thermal Core Layer: Aluminum Alloy Plate (โดยทั่วไป 5052 หรือ 6061)

-

พื้นผิวเสร็จสิ้น: ทองคำแช่นิเกิลแบบไม่ใช้ไฟฟ้า (Ni/Au)

-

Legend Ink: High-Temperature Resistant White LPI Solder Mask, Black Legend Ink

Board Construction:

The stack-up, from top to bottom, เป็น: White Solder Mask Layer (with Black Legend) -> 2u” ENIG Pads/Traces Layer -> FR-4 Dielectric Insulation Layer -> Aluminum Metal Substrate. This “sandwich” construction ensures optimal electrical performance alongside superior thermal management.

Core Performance & คุณสมบัติ:

-

Superior Heat Dissipation: Integrated aluminum core provides thermal conductivity far exceeding standard FR-4 PCB boards, effectively reducing component operating temperatures by 20%-40%.

-

ความน่าเชื่อถือสูง: ที่ FR-4 TG150 material offers enhanced thermal endurance, maintaining mechanical stability in high-temperature environments and minimizing solder joint fatigue from CTE mismatch.

-

ความสามารถในการบัดกรีที่ดีเยี่ยม: ที่ ทองคำแช่นิเกิลแบบไม่ใช้ไฟฟ้า (เห็นด้วย) finish provides a flat, oxidation-resistant, and highly solderable surface, suitable for fine-pitch components.

-

Mechanical Robustness: The 1.6mm overall thickness combined with the metal core results in a บอร์ด PCB with higher mechanical strength, resisting bending and vibration.

-

Clear Identification: The white-on-black legend printing offers excellent readability during assembly and servicing.

-

Cost-Effective Solution: Compared to full ceramic substrates or high-end pure aluminum PCBs, this solution provides superior thermal performance while maintaining a competitive การผลิต PCB ค่าใช้จ่าย.

กระบวนการผลิต & Key Techniques

UGPCB strictly adheres to มาตรฐาน IPC. The core manufacturing workflow is as follows:

-

Panelization & Prep: Cutting the FR-4 and aluminum core laminate material.

-

Imaging & Pattern Transfer: Transferring the circuit pattern onto the copper layer via photolithography.

-

การแกะสลัก: Forming precise copper traces.

-

การขุดเจาะ (if required): For mounting holes or thermal vias.

-

หน้ากากบัดกรี & Legend Application: Coating with white LPI solder mask, followed by exposure, การพัฒนา, and printing of black legend.

-

พื้นผิวเสร็จสิ้น: Applying a precisely controlled Electroless Nickel Immersion Gold process to create nickel and gold layers on exposed pads, ensuring a consistent gold thickness of 2 micro-inches.

-

Routing & Profiling: Board outline routing or V-scoring.

-

Electrical Test & การตรวจสอบขั้นสุดท้าย: 100% Flying Probe or Fixture testing to ensure circuit continuity and electrical isolation.

แอปพลิเคชันหลัก & ใช้เคส

นี้ High-Thermal Single-Side Aluminum Core PCB is the ideal choice for a wide range of medium-to-high power electronic applications requiring efficient cooling:

-

LED Lighting: LED Heat Sink Boards (PCB MCPCBs) for high-power LED street lights, industrial lamps, and automotive lighting, significantly extending LED lifespan by mitigating lumen depreciation.

-

โมดูลพลังงาน: Switching Mode Power Supplies (เอสเอ็มพีเอส), DC-DC converters, and power sections of motor drivers.

-

อุปกรณ์อิเล็กทรอนิกส์ยานยนต์: Power management systems and LED controller boards in new energy vehicles.

-

อุปกรณ์อิเล็กทรอนิกส์สำหรับผู้บริโภค: High-end audio amplifiers, power amplifier modules in routers.

-

การควบคุมทางอุตสาหกรรม: IGBT heatsink substrates in variable frequency drives and servo drives.

Why Choose UGPCB’s Aluminum Base PCB Solution?

As a professional ผู้ผลิต PCB, UGPCB not only supplies standard products but also offers customization based on your specific thermal requirements (เช่น, locally thickened aluminum base), electrical insulation needs, and mechanical form factors. We are committed to supporting your project from initial design review through to volume production, การทำให้มั่นใจ บอร์ด PCB quality and on-time delivery.

Contact us today for a free quote and technical consultation on your High-Power Thermal Management PCB Solution. Let our expert design and manufacturing capabilities enhance the reliability and performance of your products.