TBS-LAD-860 Aluminum Laser Drilling Machine: Revolutionizing PCB Manufacturing at UGPCB

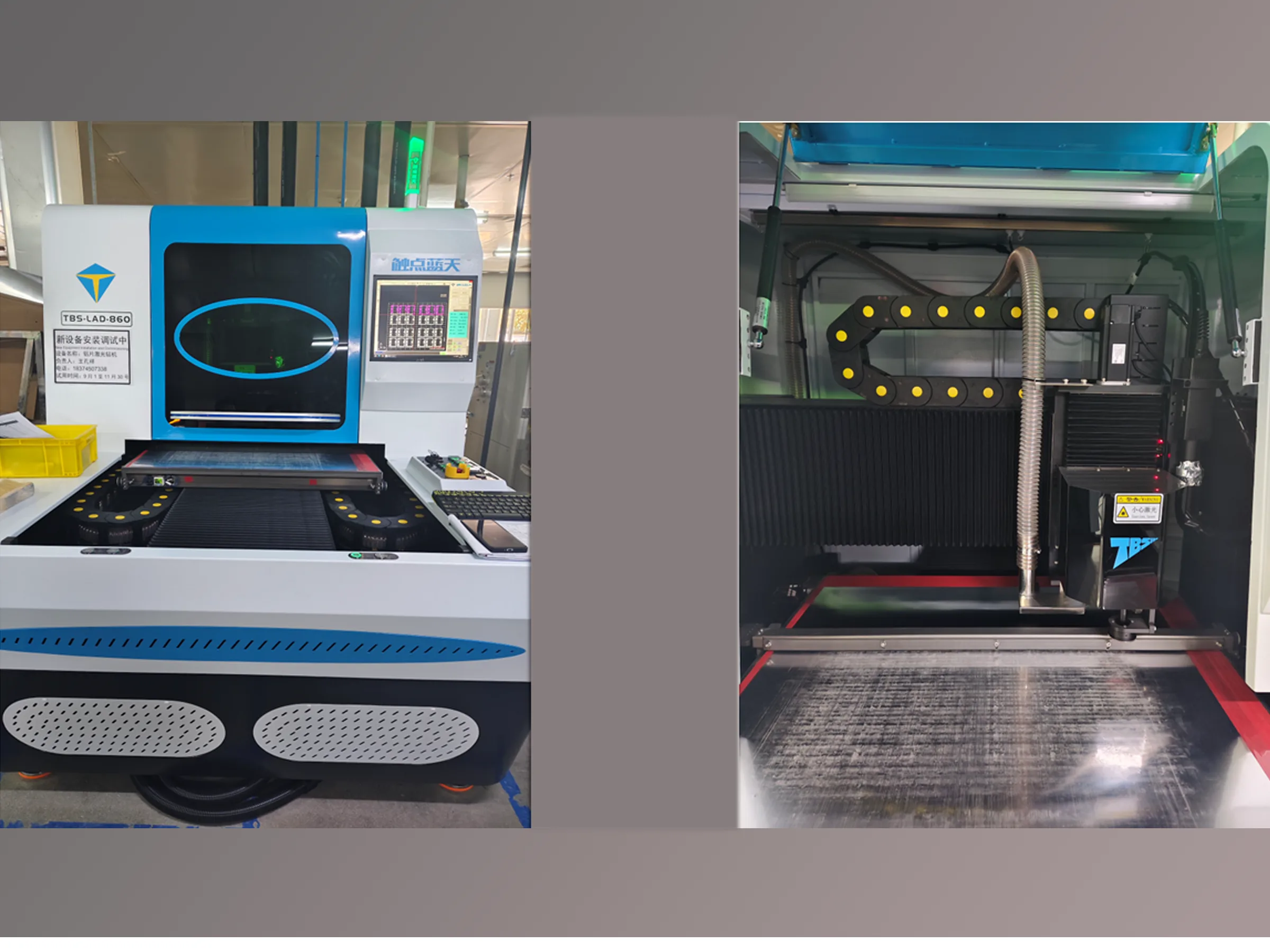

In the rapidly evolving world of electronics, the demand for high-density interconnect (HDI) PCBs and high-performance PCBA is pushing manufacturers to adopt more advanced manufacturing technologies. At UGPCB, we stay ahead of these trends by investing in state-of-the-art equipment that empowers our clients to innovate. Our latest acquisition, the TBS-LAD-860 Aluminum Laser Drilling Machine, represents a significant leap forward in our capabilities for aluminum-based PCB fabrication and complex PCBA assembly support.

This machine is not just another tool in our workshop; it is a cornerstone of our strategy to provide the most reliable and precise PCB and PCBA services in the industry. Designed to tackle the most challenging microvia drilling tasks, the TBS-LAD-860 enables us to serve cutting-edge applications in LED lighting, automotive electronics, and 5G infrastructure with unparalleled quality and efficiency.

1. Technical Superiority of the TBS-LAD-860 Laser Drilling System

The TBS-LAD-860 is engineered specifically for processing challenging substrate materials like aluminum, which is prized for its excellent thermal conductivity but notoriously difficult to drill with traditional methods.

1.1. Core Technical Specifications

Our TBS-LAD-860 system incorporates several groundbreaking features that set it apart from conventional drilling equipment:

-

Laser Source: A specialized 860nm, 1W, fiber-coupled laser diode system provides the ideal wavelength for aluminum material processing, delivering superior absorption characteristics for clean, precise results.

-

Beam Quality: With a beam divergence of 0.22 NA and advanced beam shaping optics, the system achieves an exceptionally focused spot size capable of creating microvias as small as 50μm in diameter – essential for today’s HDI PCB designs.

-

Processing Speed: The system’s high-speed galvanometers and precision staging enable drilling rates of up to 500 holes per second on aluminum substrates, dramatically increasing throughput compared to mechanical drilling .

-

Positioning Accuracy: Incorporating a high-precision image recognition and positioning system with automatic target recognition, the TBS-LAD-860 achieves remarkable positioning accuracy of ±3μm , ensuring perfect alignment with your PCB panel layout.

-

Cooling System: An integrated closed-loop cooling system maintains optimal laser temperature with ±0.1°C stability , ensuring consistent processing quality and extending laser lifespan – a critical consideration for high-volume production environments.

2. Solving Aluminum PCB Manufacturing Challenges

Aluminum-based PCBs present unique manufacturing hurdles that conventional drilling methods struggle to overcome. The TBS-LAD-860 is specifically engineered to address these challenges head-on.

2.1. Overcoming Traditional Aluminum Drilling Limitations

Traditional mechanical drilling of aluminum PCBs faces inherent limitations that impact both quality and cost:

-

Eliminating Mechanical Stress: Mechanical drilling exerts physical pressure on the substrate, often causing deformation, delamination, or burring of the delicate aluminum material . The TBS-LAD-860’s non-contact laser drilling process completely eliminates these issues.

-

Solving Tool Wear Problems: Aluminum’s properties cause rapid wear of mechanical drill bits, requiring frequent replacement and resulting in inconsistent hole quality over time . Our laser solution maintains consistent performance without degradation, ensuring uniform quality throughout production runs.

-

Preventing Thermal Damage: Unlike some laser systems that can generate excessive heat, the TBS-LAD-860 utilizes optimized pulse parameters that create a “cold processing” effect, minimizing the heat-affected zone (HAZ) to less than 10μm around each via . This preserves the integrity of the aluminum substrate and adjacent circuitry.

The transition to laser technology for aluminum PCB drilling represents more than just an incremental improvement – it’s a fundamental transformation in manufacturing capability that enables new design possibilities.

3. UGPCB’s Technical Edge in PCB and PCBA Manufacturing

At UGPCB, our investment in the TBS-LAD-860 laser drilling system is complemented by our comprehensive technical expertise and quality-focused processes across both PCB fabrication and PCBA assembly.

3.1. Advanced Process Capabilities

Our manufacturing ecosystem is designed to provide seamless integration from design to finished assembly:

-

HSP and Embedded Copper Technologies: We’ve developed specialized expertise in HSP (High-Speed Plating) and buried/embedded copper technologies , which complement the precision of our laser drilling to create superior interconnects in complex multilayer boards.

-

Full Process Control: UGPCB maintains complete control over the entire PCB manufacturing process , from material selection and laser drilling to plating, patterning, and final testing. This vertical integration ensures consistency, reduces lead times, and allows for better quality management.

-

Advanced Inspection and Testing: We employ industry-leading inspection technologies including SEM/EDX and HAST (Highly Accelerated Stress Test) equipment to validate the quality of our laser-drilled vias and overall board reliability, providing our customers with confidence in their products.

3.2. PCBA Assembly Support

Our capabilities extend beyond fabrication to encompass complete PCBA assembly services:

-

DFM Analysis: Our engineering team provides comprehensive Design for Manufacturing analysis specifically addressing the implications of laser-drilled aluminum PCBs in your assembly process.

-

Thermal Management Expertise: With aluminum PCBs often being used in high-power applications, we offer specialized support for thermal interface material selection and assembly processes to maximize the thermal performance of your final product.

-

Value-Added Services: We provide a complete suite of assembly services including component procurement, automated assembly, functional testing, and fulfillment – creating a single-source solution for your aluminum PCB and PCBA needs.

4. Application-Specific Benefits Across Industries

The TBS-LAD-860 laser drilling system enhances our ability to serve demanding applications across multiple sectors:

4.1. LED Lighting Systems

For LED applications, aluminum PCBs provide critical thermal management, and the quality of microvias directly impacts heat dissipation efficiency:

-

The TBS-LAD-860 enables creation of high-density microvia arrays that significantly improve thermal transfer from LED components to the heat sink .

-

Our laser drilling process achieves consistent via wall quality with roughness below Ra 0.6μm , optimizing thermal conduction paths.

-

The result is improved LED lifespan and performance – with demonstrated longevity exceeding 50,000 hours in customer applications .

4.2. Automotive Electronics

The automotive industry presents particularly challenging environments where reliability is non-negotiable:

-

Laser-drilled aluminum PCBs manufactured at UGPCB demonstrate exceptional stability across extreme temperature ranges (-40°C to 85°C) , making them ideal for battery management systems (BMS), power controllers, and lighting applications.

-

The absence of mechanical stress during drilling eliminates potential failure initiation points, enhancing vibration resistance and long-term reliability in demanding automotive environments .

4.3. 5G Infrastructure and RF Applications

The high-frequency demands of 5G infrastructure require precision that only laser drilling can provide:

-

Our TBS-LAD-860 system enables tighter via spacing (as small as 100μm) compared to mechanical drilling, allowing for more compact RF circuit designs with improved signal integrity.

-

The precision of laser-drilled vias reduces signal loss and impedance discontinuities at higher frequencies, critical for 5G performance .

5. Quantifiable Manufacturing Advantages

The implementation of the TBS-LAD-860 aluminum laser drilling system delivers measurable benefits across key manufacturing metrics:

5.1. Quality and Precision Metrics

-

Positioning Accuracy: Achieves ±3μm positioning accuracy versus ±15μm with mechanical drilling

-

Via Wall Quality: Produces via walls with surface roughness of Ra 0.6μm or less compared to Ra 1.2-2.0μm with mechanical drilling

-

Yield Improvement: Increases first-pass yield to 99% or higher from approximately 85% with mechanical methods

5.2. Efficiency and Throughput Gains

-

Processing Speed: Enables drilling rates of 400-600 panels per hour (600mm × 600mm size) compared to 150-200 panels with mechanical drilling

-

Elimination of Secondary Operations: Removes need for de-burring and cleaning steps required after mechanical drilling

-

Tooling Cost Reduction: Eliminates drill bit wear and replacement costs – a significant saving considering carbide drill bits for aluminum need replacement after a few hundred panels

To quantify the capability of different drilling approaches, the aspect ratio (AR) formula is essential:

AR = Hole Depth / Drill Diameter

While mechanical drilling typically achieves aspect ratios of 16:1 for plated through-holes, our laser drilling process excels in microvia applications with aspect ratios of 0.9:1 , perfectly suited for HDI designs on aluminum substrates.

6. UGPCB’s Commitment to Technological Leadership

Our investment in the TBS-LAD-860 aluminum laser drilling system reflects UGPCB’s broader commitment to maintaining technological leadership in PCB and PCBA manufacturing. We recognize that our customers’ success depends on access to manufacturing capabilities that can transform their most innovative design concepts into reliable, high-performance products.

Beyond advanced equipment, we offer:

-

Collaborative Engineering Support: Our technical team works closely with customers to optimize designs for manufacturability and performance, leveraging the full potential of laser drilling technology.

-

Rapid Prototyping Services: We offer quick-turn prototyping on aluminum substrates with laser-drilled vias, enabling faster design iteration and time-to-market.

-

Volume Manufacturing Scalability: With the high throughput of our TBS-LAD-860 systems, we seamlessly transition from prototype to volume production while maintaining consistent quality.

Conclusion: Partner with UGPCB for Your Aluminum PCB and PCBA Needs

The TBS-LAD-860 Aluminum Laser Drilling Machine represents the cutting edge of PCB manufacturing technology, specifically addressing the challenges of aluminum substrate processing. This investment reinforces UGPCB’s position as a manufacturer capable of supporting the most demanding applications across LED lighting, automotive electronics, 5G infrastructure, and power systems.

Whether you are developing a new product that requires the thermal performance of aluminum substrates or seeking to improve the reliability and performance of existing designs, UGPCB has the technology, expertise, and manufacturing excellence to meet your requirements.

Ready to experience the UGPCB difference in aluminum PCB manufacturing and PCBA assembly?

Contact our engineering team today to discuss your project requirements or to request a quotation. Visit our website or email us at to initiate a conversation about how our TBS-LAD-860 laser drilling capabilities can enhance your products.