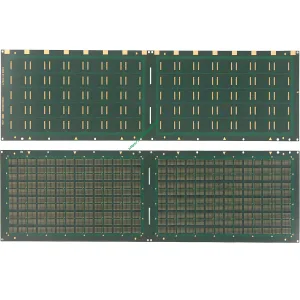

Lead the High-Speed Era: UGPCB’s 4-Layer DDR Substrate Board – The Superior Interconnect Solution for Your Core ICs

In the booming landscape of high-performance computing, الذكاء الاصطناعي, and next-generation communication devices, every advancement in Double Data Rate (DDR) technology places stricter demands on PCB substrates. Leveraging deep expertise in high-end PCB manufacturing و الركيزة IC الحلول, UGPCB introduces its premium 4-Layer DDR Substrate Board. Engineered with cutting-edge materials, it is specifically designed to carry high-performance memory chips (على سبيل المثال, DDR4, DDR5, LPDDR), serving as your reliable partner in the pursuit of ultimate speed and stability.

Product Overview & Definition

أ 4-Layer DDR Substrate Board is a High-Density Interconnect (مؤشر التنمية البشرية) printed circuit board designed for packaging and connecting Dynamic Random-Access Memory (DDR) chips. It acts as a critical bridge between the chip and the mainboard, responsible for transmitting high-speed signals, distributing power, and providing stable mechanical support. Unlike standard PCB boards, DDR substrates demand near-perfect signal integrity, الإدارة الحرارية, and dimensional accuracy. This product from UGPCB is tailor-made to meet these stringent requirements.

اعتبارات التصميم الحرجة

-

Precise Impedance Control: Paramount for DDR PCB design, it minimizes signal reflection and distortion during high-speed data transmission.

-

Power Integrity (PI): Dedicated power and ground plane design ensures clean, stable power delivery, reducing noise interference on critical signals.

-

سلامة الإشارة (و): Optimized routing using microstrip and stripline structures minimizes crosstalk and delay, forming the foundation for stable performance post-تجميع PCBA.

-

-

الإدارة الحرارية: The substrate material must exhibit excellent thermal properties to aid chip dissipation and ensure long-term reliability.

How It Works

The 4-Layer DDR Substrate connects the hundreds of micro-pins of a memory chip to the corresponding motherboard circuits via its precise internal layers. Its “sandwich” stack-up (Signal-Ground-Power-Signal) provides clear return paths for high-speed signals, effectively suppressing Electromagnetic Interference (emi). The soft gold surface finish ensures a reliable, low-resistance solder joint with the chip’s solder balls (على سبيل المثال, in BGA packages).

التطبيقات الأولية & تصنيف

-

التطبيقات الأولية: Extensively used in servers, data center switches, high-end GPUs, AI accelerator cards, network storage devices, and any cutting-edge electronic product requiring high-speed, high-capacity memory.

-

تصنيف:

-

By Layer Count: Beyond standard 4-layer, designs can extend to 6, 8, or more layers based on complexity.

-

By Material: Can be categorized into standard FR-4, Mid-Loss, and this product’s focus – Low-Loss material substrates.

-

مواد & Performance Specifications

| المعلمة | Specification | Performance Advantage |

|---|---|---|

| Core Material | Mitsubishi Gas Chemical HL832 | Industry-recognized, عالية الأداء, low-loss (Low Df) laminate designed for high-speed digital circuits, significantly reducing signal transmission loss. |

| عدد الطبقة | 4 طبقات | Optimal “Signal-Ground-Power-Signal” stack-up, balancing design complexity, يكلف, and performance. |

| سمك الانتهاء | 0.25مم | Ultra-thin profile, conforming to compact chip packaging trends for integration into miniaturized devices. |

| سمك النحاس | 0.5أوقية (17.5ميكرومتر) | Standard starting weight, suitable for fine-line etching; can be plated up for higher current needs. |

| Solder Mask Color | أخضر (AUS308) | Provides excellent insulation protection and visual contrast for Optical Inspection (الهيئة العربية للتصنيع) بعد تجميع ثنائي الفينيل متعدد الكلور. |

| الانتهاء من السطح | Soft Gold (يوافق) | Excellent surface planarity and low hardness, ensures superior compatibility with wire bonding or BGA solder balls for reliable connections. |

| Minimum Drilled Hole Size | 100ميكرومتر | Supports high-density micro-via design for complex chip pinout interconnection. |

| دقيقة. Line Width/Space | 50ميكرومتر / 75ميكرومتر | High-precision routing capability allows more high-speed lines in limited space, meeting high-density interconnect PCB design needs. |

Product Structure & الميزات الرئيسية

-

Structure: Typical 4-layer sequential lamination: Top Layer (Signal/Components) -> Inner Layer 1 (Solid Ground Plane) -> Inner Layer 2 (Solid Power Plane) -> Bottom Layer (Signal/Components). This structure offers optimal shielding for high-speed signals.

-

الميزات الرئيسية:

-

Superior High-Speed Performance: HL832 low-loss material ensures excellent signal integrity for high-frequency DDR signals.

-

High-Density Interconnect Capability: 100μm micro-vias and 50μm line width technology support advanced chip packaging.

-

High Reliability: ENIG surface finish offers excellent solderability and oxidation resistance for long-term stability.

-

Ultra-Thin & Precise: 0.25mm overall thickness meets stringent space requirements in modern electronics.

-

ملكنا تصنيع ثنائي الفينيل متعدد الكلور process adheres to the highest quality standards:

Material Prep → Inner Layer Imaging & Etching → Lamination & Drilling → Metallization & Plating → Outer Layer Imaging → Surface Finish (يوافق) → Solder Mask Application → Profiling → Electrical Test & التفتيش النهائي.

Each stage is supported by advanced inspection equipment (على سبيل المثال, الهيئة العربية للتصنيع, Flying Probe Test), ensuring every الركيزة IC delivered is flawless.

Typical Use Cases

This 4-Layer DDR Substrate is the ideal choice for:

-

Data Centers & Servers: Carrying CPU and memory modules for massive data processing.

-

منظمة العفو الدولية & Machine Learning Hardware: Memory subsystems in GPU, NPU accelerator cards.

-

High-End Communication Equipment: High-speed memory units in 5G base stations and core network gear.

-

Flagship Consumer Electronics: Main memory substrates in top-tier gaming consoles and laptops.

Why Choose UGPCB’s 4-Layer DDR Substrate?

We are more than a الشركة المصنعة لثنائي الفينيل متعدد الكلور; we are your solution provider for high-speed design challenges. With a dedicated PCB design support team, proven capabilities in multilayer PCB prototyping and mass production, and a deep understanding of signal integrity engineering, choosing UGPCB means gaining not just a high-quality substrate, but an accelerator for your product’s success.

Contact our expert team today for a project-specific quote and technical consultation. Power up your high-speed design with UGPCB!