UGPCB Standard 2-Layer Rigid PCB: Reliable 1.6mm FR-4 Circuit Boards for Demanding Applications

At the heart of modern electronics, ال لوحة الدوائر المطبوعة (ثنائي الفينيل متعدد الكلور) acts as the foundational platform, interconnecting components and routing signals with precision. UGPCB Standard 2-Layer Rigid PCB, built with a robust 1.60mm thickness and high-performance FR-4 TG150 material, represents the optimal balance of durability, electrical performance, and cost-effectiveness for a wide range of applications. هذا double sided PCB is a proven solution for prototypes and medium-complexity electronic devices.

Product Definition & تصنيف

Technical Classification:

-

By Layer Count: Double-Sided PCB / Two Layer PCB

-

By Substrate Rigidity: Rigid PCB

-

By Base Material: Glass Epoxy (فر-4) ثنائي الفينيل متعدد الكلور

-

By Flammability Rating: UL94 V-0 (inherent to FR-4)

-

By Assembly Compatibility: Through-Hole Technology (THT) and Surface-Mount Technology (سمت) capable PCB.

This product is a double sided circuit board constructed with copper clad laminate on both sides of an insulating FR-4 core. Electrical connection between layers is achieved via plated through-holes (PTH). ال 1.60مم (approximately 1/16 inch) board thickness is an industry-standard, offering excellent mechanical stability.

بناء & مواصفات المواد

Layer Stack-Up:

هذا 2 layer rigid PCB structure is as follows (top to bottom):

-

Top Solder Mask (أبيض): Insulating layer to prevent solder bridges.

-

Top Copper Layer (1 أوقية, ~35µm): Etched to form conductive traces and pads.

-

Insulating Core Substrate (فر-4, Tg150): Provides mechanical support and electrical insulation.

-

Bottom Copper Layer (1 أوقية, ~35µm): Etched to form bottom-layer circuitry.

-

Bottom Solder Mask (أبيض): Insulating protective layer.

-

Silkscreen Legend (أسود): Component designators, logos, and markings.

Key Materials:

-

Base Laminate: FR-4 TG150. This denotes a flame-retardant glass-reinforced epoxy laminate with a Glass Transition Temperature (تيراغرام) of 150°C. It offers superior mechanical strength, العزل الكهربائي, and thermal reliability for a rigid printed circuit board, making it the industry’s most cost-effective choice.

-

احباط النحاس: Standard 1-ounce (أوقية) Electro-Deposited copper for optimal conductivity and current carrying capacity.

-

الانتهاء من السطح: Lead-Free Hot Air Solder Leveling (ينزف). A cost-effective and reliable PCB surface finish that provides excellent solderability, good shelf life, and robust protection against oxidation.

-

Inks: High-quality photo-imageable white solder mask ink and durable black epoxy silkscreen ink.

(Image Suggestion: Cross-sectional diagram of the PCB stack-up)

Alt Tag: Detailed cross-sectional diagram of a 2 layer rigid PCB showing copper, FR-4 core, and solder mask layers.

إرشادات التصميم & Operational Principle

اعتبارات التصميم الحرجة:

-

Via Design: Maximize the routing space of your double sided تصميم ثنائي الفينيل متعدد الكلور by strategically placing Plated Through-Holes (PTHs) for inter-layer connections.

-

تتبع العرض/التباعد: For 1oz copper, a standard minimum trace/space is 6mil/6mil (~0.15mm) to ensure reliable manufacturability and current capacity.

-

Pad & Hole Annular Ring: Ensure adequate pad size relative to the drill hole to guarantee a strong connection for تجميع ثنائي الفينيل متعدد الكلور والموثوقية.

-

قناع اللحام & Silkscreen: White solder mask aids visual inspection during SMT assembly, while clear black silkscreen is crucial for PCB prototyping and repair.

Operational Principle:

A PCB does not generate function but enables it through its predefined conductive pathways. The etched copper traces replace discrete wiring, providing electrical connections between components. The insulating FR-4 substrate prevents short circuits. Plated through-holes (PTHs) serve as vertical conduits, connecting the top and bottom PCB copper layers, thereby doubling the available routing area compared to a single-sided board and increasing design flexibility.

خصائص الأداء & Advantages

-

High Reliability: ال FR-4 TG150 substrate ensures stable performance in environments below its Tg, offering excellent thermal and mechanical stability for a rigid circuit board.

-

Excellent Electrical Properties: Low dielectric constant and dissipation factor support the signal integrity requirements of most digital and analog circuits.

-

High Manufacturability: ال 1.6مم standard PCB thickness و Lead-Free HASL process are mature, ensuring high yield, cost control, and fast lead times.

-

Superior Solderability: The HASL finish offers a flat, wettable surface ideal for both through-hole soldering و SMT soldering processes.

-

Clear Identification: High-contrast white solder mask with black legend facilitates efficient ثنائي الفينيل متعدد الكلور تقتيش, اختبار, and rework.

-

Environmental Compliance: Lead-Free HASL finish complies with RoHS and other environmental directives.

Standard Manufacturing Process Flow

UGPCB adheres to IPC standards throughout our PCB fabrication process:

Panelization → Drilling → Electroless Copper Deposition → Dry Film Lamination & Imaging → Copper Plating → Etching → Solder Mask Application & Curing → Silkscreen Printing → Surface Finish (Lead-Free HASL) → Profiling/Routing → Electrical Testing (مسبار الطيران) → Final Automated Optical Inspection (الهيئة العربية للتصنيع) → Packaging & Shipment.

التطبيقات الأولية & Use Cases

This versatile two layer rigid PCB is widely used in industries that demand a balance of reliability and value:

-

Industrial Controls: PLC interfaces, sensor modules, motor drives, HMI controller boards.

-

الالكترونيات الاستهلاكية: Smart appliance controllers, audio amplifiers, power supplies, educational kits.

-

الاتصالات السلكية واللاسلكية: Router/switch peripheral boards, RF antenna modules, network monitoring units.

-

إلكترونيات السيارات: Infotainment systems, lighting control modules, body control modules (non-safety critical).

-

Power Electronics: Smart meter PCBs, UPS control boards, solar inverter circuitry.

-

Test & Measurement: Data acquisition cards, instrument control panels, handheld tester boards.

Why Choose UGPCB for Your 2-Layer PCB Needs?

Choosing UGPCB means partnering with a reliable الشركة المصنعة لثنائي الفينيل متعدد الكلور committed to quality. We specialize in نموذج ثنائي الفينيل متعدد الكلور and medium-volume production, implementing rigorous Electrical Testing and IPC-A-600 based inspection on every board. From simple 2 layer boards to complex multi-layer designs, نحن نقدم الخبراء PCB design for manufacturing (سوق دبي المالي) support and a streamlined supply chain.

Contact us today for a competitive quote and swift lead time on your 1.6mm FR-4 2-Layer PCB project!

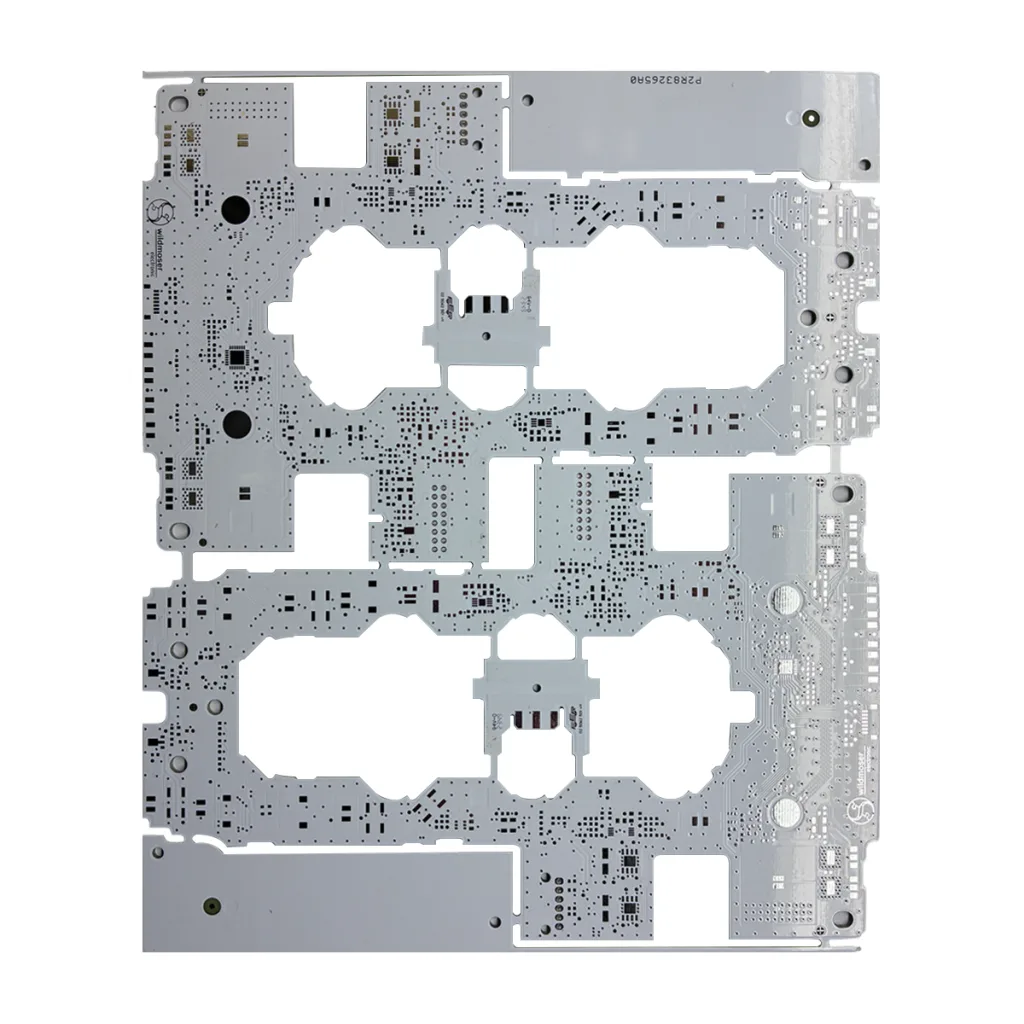

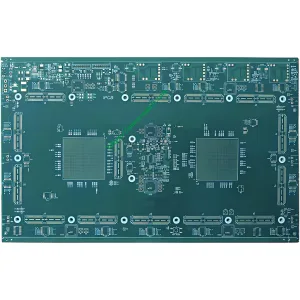

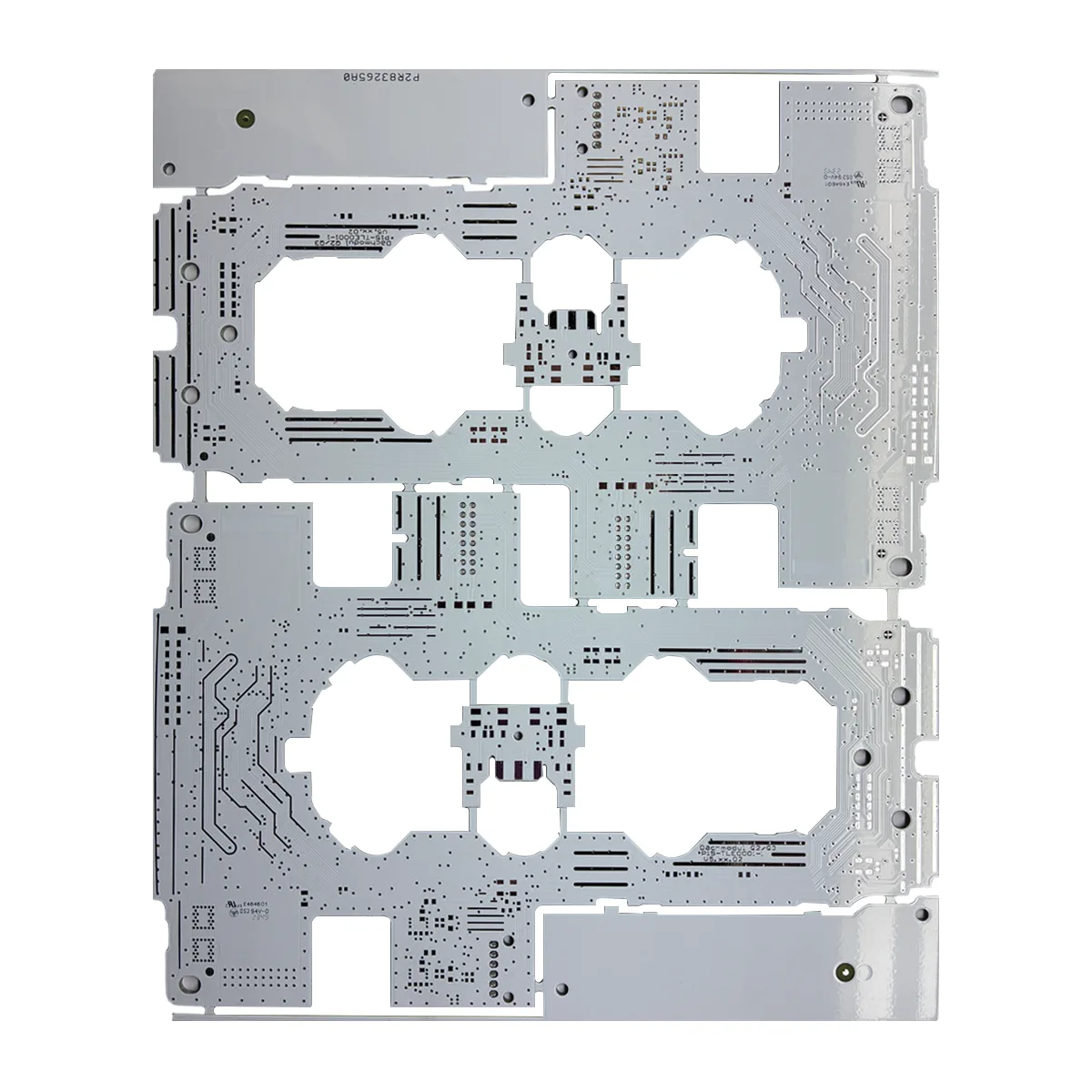

(Image Suggestion: Gallery of finished PCBs with different designs)

Alt Tag: Gallery of various 2 layer rigid PCB examples manufactured by UGPCB with white solder mask.

شعار UGPCB

شعار UGPCB