Introduction to UGPCB Micro PCB Solutions

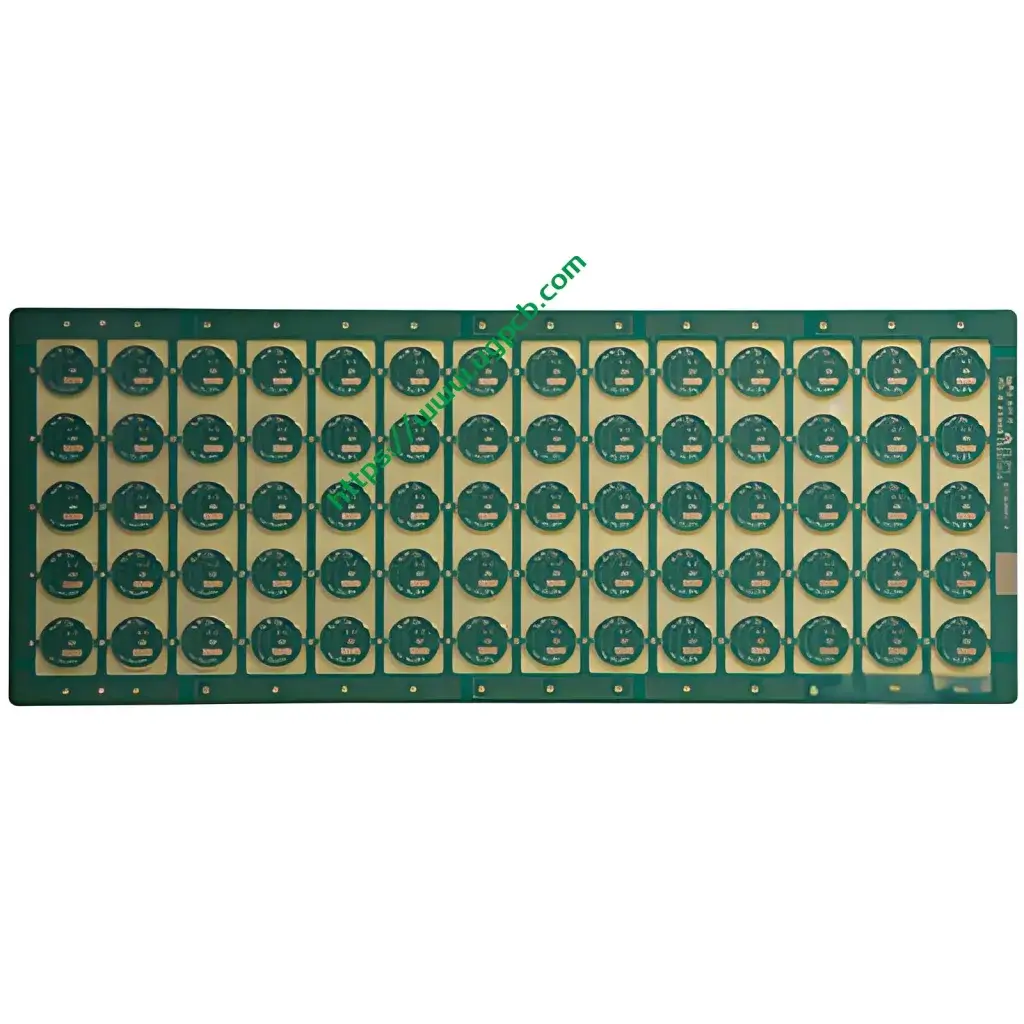

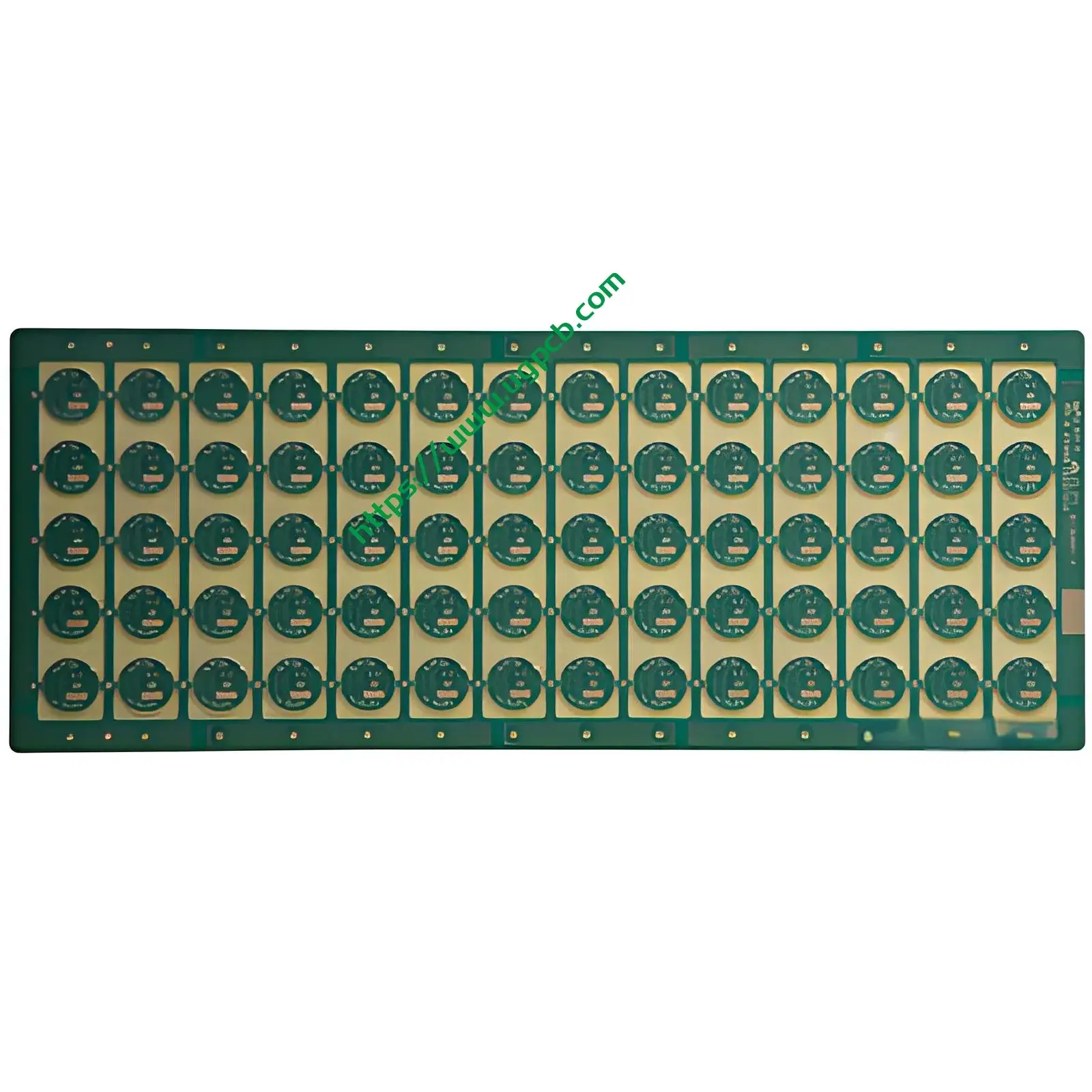

UGPCB specializes in manufacturing Micro PCB و Ultra Small Size PCB منتجات, designed for high-density, compact electronic applications. These مركبات ثنائي الفينيل متعدد الكلور feature a 0.6mm finished thickness, 4-layer construction, and precise 6mil trace/space capabilities, making them ideal for advanced PCB and ثنائي الفينيل متعدد الكلور projects in industries like IoT, الأجهزة الطبية, والإلكترونيات الاستهلاكية. With gold-plated surfaces and FR-4 material, UGPCB ensures reliability and performance for demanding environments.

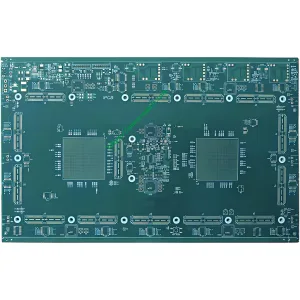

What Are Micro PCBs and Ultra Small Size PCBs?

Micro PCBs و Ultra Small Size PCBs refer to لوحات الدوائر المطبوعة with exceptionally small dimensions, such as UGPCB’s minimum finished board size of 0.5mm x 1.0mm. These boards support high component density and are engineered for applications where space is limited. They are a key component in miniaturized تصميم ثنائي الفينيل متعدد الكلور و advanced تجميع PCBA, enabling sleeker and more efficient electronic products.

Key Design Considerations for Micro PCBs

When designing Micro PCBs, engineers must account for several factors to ensure functionality and manufacturability:

-

Trace and Space Requirements: UGPCB’s minimum trace and space of 6mil (0.15مم) demand precise تخطيط ثنائي الفينيل متعدد الكلور techniques to avoid signal interference.

-

Layer Management: The 4-layer structure allows for separated power, ground, and signal layers, optimizing ثنائي الفينيل متعدد الكلور عالي السرعة أداء.

-

المعالجة السطحية: Gold-plating with 0.2μm thickness enhances conductivity and corrosion resistance, critical for reliable PCBA processes.

-

اختيار المواد: FR-4 material provides excellent thermal and mechanical stability, supporting durable تصنيع ثنائي الفينيل متعدد الكلور.

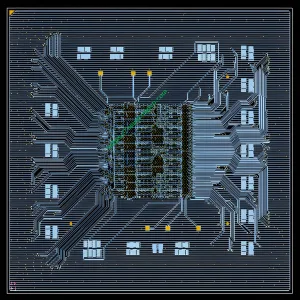

How Micro PCBs Work: Basic Principles

Micro PCBs function by interconnecting electronic components through conductive copper traces embedded in insulating layers. In UGPCB’s 4-layer design, signals are routed efficiently to minimize noise and crosstalk, supporting complex PCB circuitry in ultra-small formats. This makes them suitable for low-power PCB applications و high-density PCBA integration, where precise electrical pathways are essential.

Applications and Uses of Micro PCBs

UGPCB’s Micro PCBs are versatile and used across various sectors:

-

Wearable Technology: For fitness trackers and smartwatches requiring compact PCB solutions.

-

Internet of Things (إنترنت الأشياء): Enabling small sensors and connected devices with efficient PCBA designs.

-

الإلكترونيات الطبية: In implantable devices and diagnostic tools where reliable micro PCB performance is critical.

-

الالكترونيات الاستهلاكية: Powering smartphones, drones, and other portable gadgets with space-saving PCB layouts.

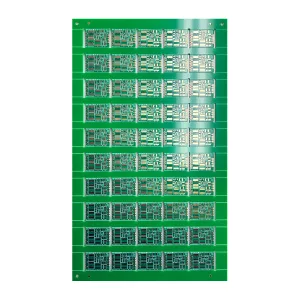

Classification of Micro PCBs

Micro PCBs can be categorized based on their specifications:

-

By Size: Ultra small size PCBs (على سبيل المثال, sub-1mm dimensions) versus standard micro PCBs.

-

By Layer Count: جانب واحد, على الوجهين, or multi-layer (like UGPCB’s 4-layer boards) ل custom PCB projects.

-

By Application: High-frequency, flex-rigid, or standard FR-4 boards tailored for specialized PCBA services.

Materials Used in UGPCB Micro PCBs

UGPCB employs FR-4 material for its Micro PCBs, a flame-retardant epoxy laminate known for:

-

High Dielectric Strength: Ideal for insulated PCB designs.

-

المقاومة الحرارية: Withstands soldering temperatures during تجميع PCBA.

-

Cost-Effectiveness: Balances performance and affordability for volume PCB production.

Performance Specifications of UGPCB Micro PCBs

Key performance metrics include:

-

سمك الانتهاء: 0.6مم, supporting slim PCB profiles for tight spaces.

-

سمك النحاس: 1أوقية, ensuring adequate current carrying capacity for stable PCB operations.

-

Durability: Gold-plating (0.2ميكرومتر) resists oxidation, enhancing long-term PCBA reliability.

-

Operational Range: Suitable for wide-temperature PCB applications, from -50°C to 110°C.

Structural Details of 4-Layer Micro PCBs

UGPCB’s 4-layer Micro PCBs consist of:

-

Top and Bottom Layers: For component placement and routing.

-

Inner Layers: Dedicated to power and ground planes, reducing EMI in noise-sensitive PCB systems.

-

Via Structures: Microvias or through-holes facilitate inter-layer connections, crucial for complex PCBA layouts.

Key Features and Benefits of UGPCB Micro PCBs

-

Ultra-Small Size: Enables miniaturized electronics with boards as small as 0.5mm x 1.0mm.

-

دقة عالية: 6mil trace/space supports detailed PCB artwork و fine-pitch PCBA components.

-

Enhanced Reliability: Gold-plating and FR-4 material ensure robust PCB performance in harsh conditions.

-

Cost-Efficiency: Streamlined production processes reduce costs for high-volume PCB orders.

Production Process of Micro PCBs

UGPCB’s manufacturing workflow includes:

-

Design and Fabrication: Using CAD software for PCB layout optimization.

-

Layer Lamination: Bonding FR-4 layers with copper foils.

-

Etching and Drilling: Creating traces and vias with 6mil precision.

-

المعالجة السطحية: Applying gold-plating for corrosion-resistant PCB finishes.

-

Testing and Quality Control: Ensuring each board meets industry PCB standards ل error-free PCBA integration.

Common Use Scenarios for Micro PCBs

These PCBs are ideal for:

-

Portable Devices: Such as headphones and GPS units, أين lightweight PCB designs are essential.

-

Industrial Sensors: For monitoring systems requiring high-density PCB components.

-

إلكترونيات السيارات: In control modules leveraging durable PCBA assemblies.

-

Aerospace Systems: أين reliable micro PCB performance under extreme conditions is mandatory.

شعار UGPCB

شعار UGPCB