UGPCB: Expert in One-Stop PCB Design, Production & PCBA Assembly Solutions

In the rapidly evolving electronics industry, high-quality printed circuit boards (PCBs) serve as the cornerstone for achieving exceptional electronic product performance. As an industry-leading one-stop solution provider, UGPCB leverages its comprehensive strengths in PCB design capabilities, advanced manufacturing processes, PCBA assembly technologies, and extensive PCB technical resource sharing to deliver end-to-end services—from conceptualization to mass production—for global clients.

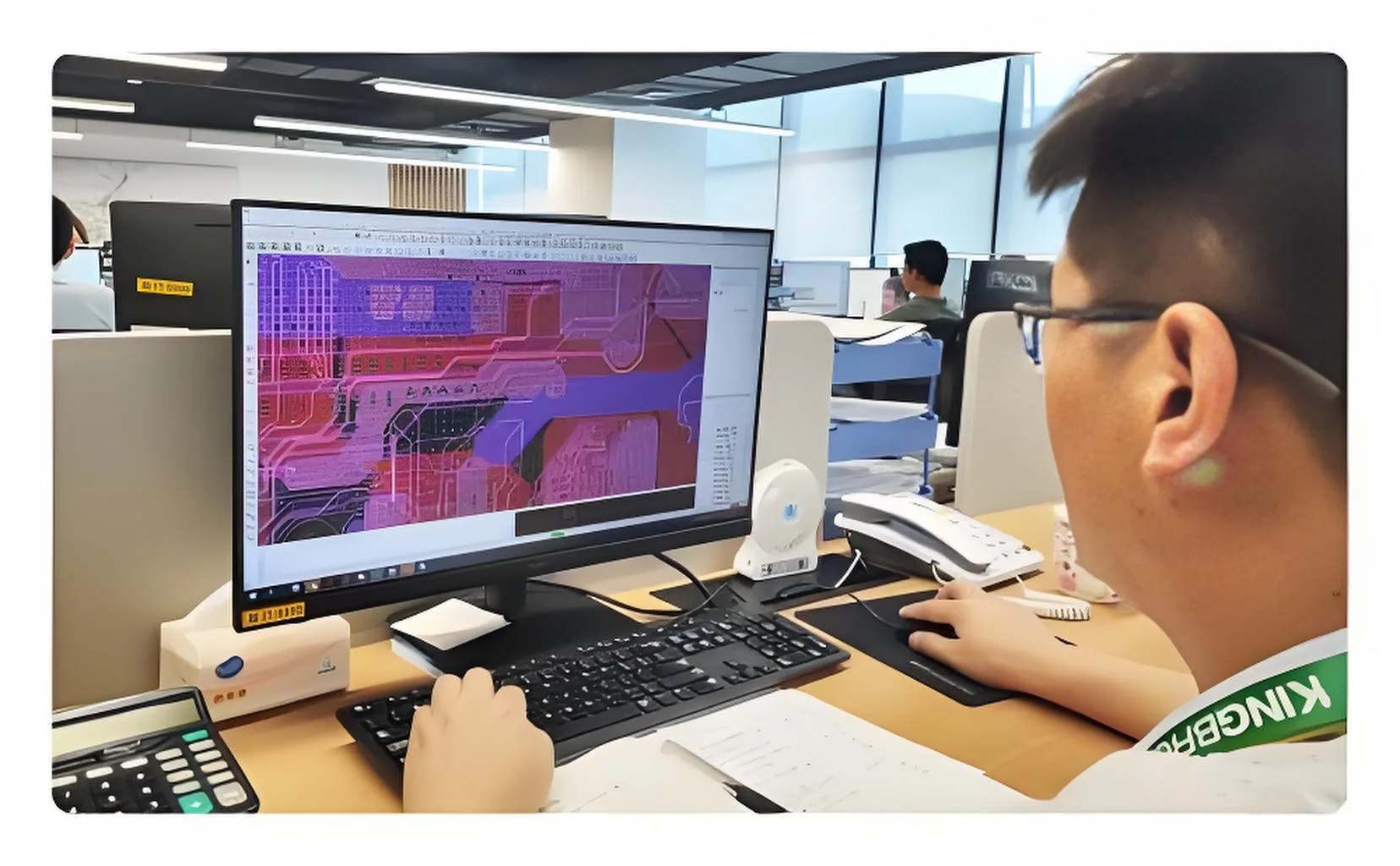

1. Superior PCB Design Expertise

UGPCB boasts an experienced PCB design team capable of handling diverse design complexities.

- Hierarchical Schematic & Layout Design

Our engineers master multiple design tools for efficient hierarchical schematic design and multi-layer layout development. Junior engineers are trained to manage single/double/multi-layer PCBs with up to 400 components and 1000 nets, ensuring rational layout/routing while addressing thermal management, structural requirements, EMI/EMC compliance, and aesthetic standards. Senior engineers tackle more complex design challenges. - Complex Packaging & High-Speed Design

We create precision packages (e.g., RJ-45 connectors with LEDs) based on specifications and physical prototypes, ensuring exact dimensions for pads and shapes. For high-speed PCBs, we adhere to strict routing protocols, implement impedance control, and optimize signal integrity to guarantee reliable high-frequency transmission.

Impedance Control Formula:

Z₀ = [87 / √(ε_r + 1.41)] × ln[5.98h / (0.8w + t)]

Where = characteristic impedance, ε_r = dielectric constant, = distance between signal layer and reference plane, = trace width, = trace thickness. Precise parameter control ensures signal integrity. - Design for Manufacturability (DFM)

We integrate DFM principles from the design phase, aligning with production requirements to eliminate defects and enhance efficiency/quality. Designers seamlessly import/export mechanical drawings, ensuring structural compatibility for flawless production transitions.

2. Advanced PCB Manufacturing Processes

UGPCB invests in cutting-edge equipment and technologies to ensure precision, quality, and reliability in PCB production.

- Multi-Layer Board Capabilities

We support 4-100 layer multi-layer PCBs and advanced HDI designs with technical specifications:- Min. trace/space: 1.5mil/1.5mil (ensuring high-frequency integrity)

- Material options: FR4, high-frequency substrates (Rogers, Taconic, etc.)

- Surface finishes: ENIG, OSP, Immersion Silver, etc.

- Hole precision: ±0.05mm (enabling high-density interconnects)

- Automated Production & Quality Inspection

Our automated lines feature intelligent exposure machines and laser drilling to minimize human error and enhance consistency. Quality systems include:- AOI: Automated defect/deviation detection

- Flying Probe: Circuit continuity/performance validation

- 24/7 in-line monitoring: Achieving >99% yield rates per batch

3. High-Precision PCBA Assembly Services

UGPCB offers end-to-end PCBA assembly by integrating SMT and through-hole technologies for reliable assembly.

- SMT Assembly Advantages

- Precision: ±0.025mm accuracy via optical alignment/flying probe, handling 0402 components, BGA, QFN, etc.

- Soldering Excellence: Reflow profiling optimizes lead-free solder joints, extending thermal fatigue life >1000 cycles.

- Efficiency: Automated lines achieve tens of thousands of placements/hour with >99.5% first-pass yield.

- Quality Testing & Reliability Validation

Our testing suite includes:- Environmental: Thermal cycling/thermal shock tests

- Mechanical: Vibration/shock simulation

- Electrical: 100% ICT coverage

4. Extensive PCB Technical Resources

UGPCB promotes knowledge sharing with downloadable resources:

- Process standards: New product fabrication reports

- Design guidelines: Company-specific design norms

- Substrate data: Panasonic and other material specs

These resources empower clients/engineers to enhance PCB design skills and tackle challenges.

5. Industry Applications & Success Stories

UGPCB solutions serve premium sectors:

- Automotive Electronics

Supplying PCBs for EV control systems and ADAS modules, ensuring reliability in harsh environments. - Medical Devices

Certified PCBs for precision monitors, endoscope boards, etc., meeting strict safety/reliability standards. - Aerospace

High-performance PCBs for satellite comms and flight controllers, operating in extreme conditions.

Case Study: A global industrial robotics leader received 100,000 6-layer PCBs within 2 weeks with <0.1% defect rate, enabling quarterly capacity targets.

6. Technological Evolution & Future Outlook

AI expansion drives global infrastructure growth, boosting PCB demand. Prismark forecasts 2024-2029 CAGR of 19.1% for AI server HDI PCBs and 17.4% for 18+ layer boards—far exceeding the industry’s 5.2% average.

UGPCB embraces trends through R&D:

- 78.46% YOY R&D growth to solidify leadership

- 100+ layer multi-layer board capabilities

- Mass production breakthrough for 6-stage 24-layer HDI

- Development of 8-stage 28-layer HDI & 16-layer Any-layer HDI

Why Choose UGPCB?

- Integrated Solutions: Full-service from design to PCBA

- Quality Assurance: Advanced equipment/strict QC

- Rapid Delivery: 3-5 day prototype turnaround, 40% faster bulk production

- Cost Efficiency: 15% procurement savings via scale/lean management

- Technical Support: 24/7 dedicated team

UGPCB delivers high-quality PCB design, manufacturing, and assembly services globally. Whether you need simple double-sided boards or complex HDI/IC substrate solutions, we provide expert, reliable outcomes.

Contact us today for tailored solutions and professional quotes. Let UGPCB’s expertise and efficiency safeguard your product success!

UGPCB LOGO

UGPCB LOGO

WeChat

Scan the QR Code with WeChat