UGPCB: World-Leading PCB Manufacturer – High-Precision Circuit Board Production, Quick-Turn Prototyping & Stencil Solutions

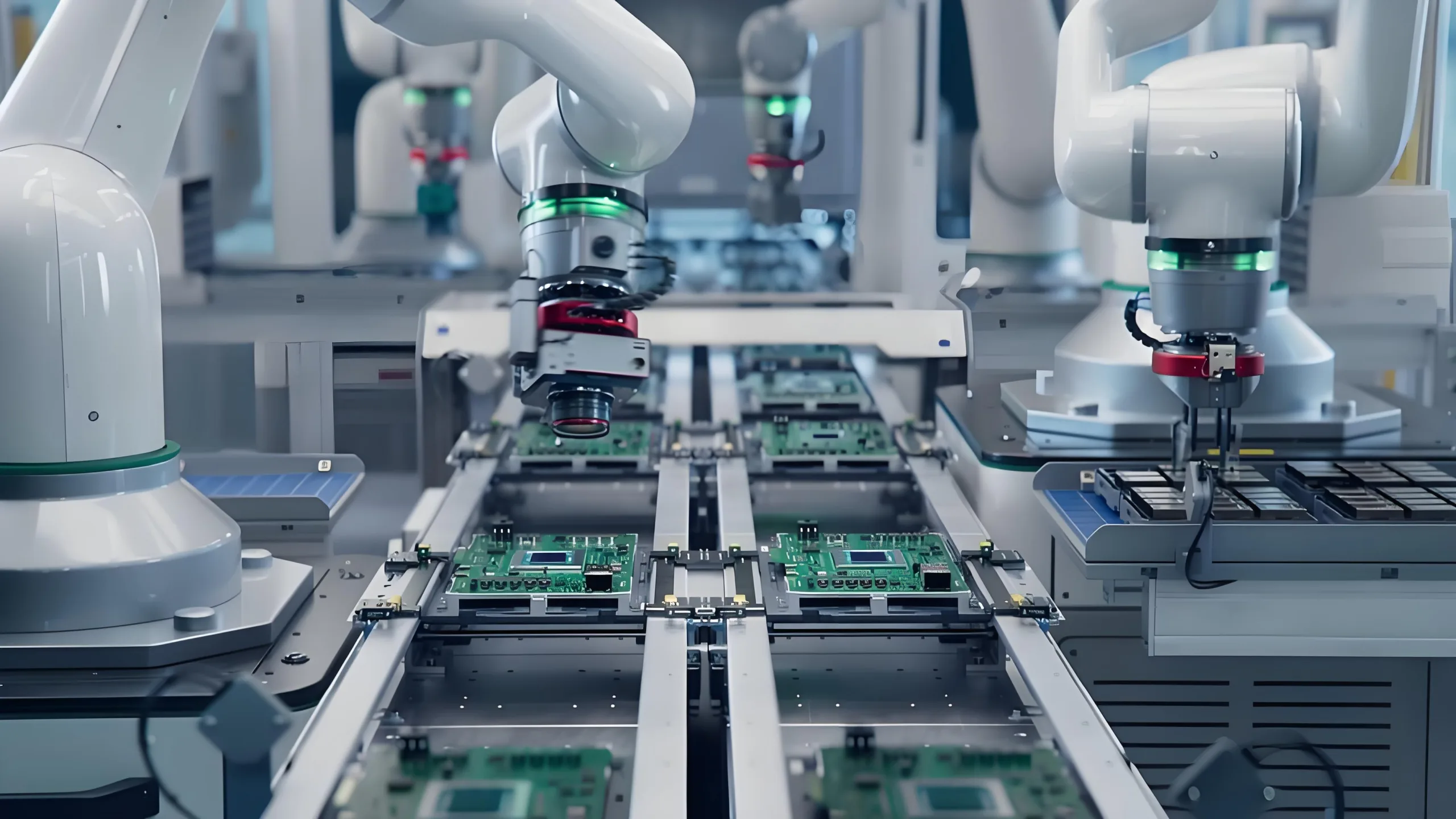

Core Value of PCB Manufacturing & Industry Challenges

As the “skeleton” of electronic devices, PCBs directly impact product performance and cost. Industry statistics indicate PCBs account for 12%-18% of total electronic product costs, and quality defects can increase post-production repair costs by 300% (IPC standards data). UGPCB leverages its 28,000 m² modern facility and 1300-person professional team (35% technical experts) to specialize in solving high-end manufacturing challenges like high-frequency microwave PCBs, HDI boards, and IC substrates.

Three Core Capabilities: UGPCB’s Manufacturing Advantages

1. Scalable PCB Production Capacity

-

Precision Equipment: Utilizes fully automated LDI exposure machines (±1.5μm accuracy) and vacuum etching lines (1.5/1.5 mil line width/spacing).

-

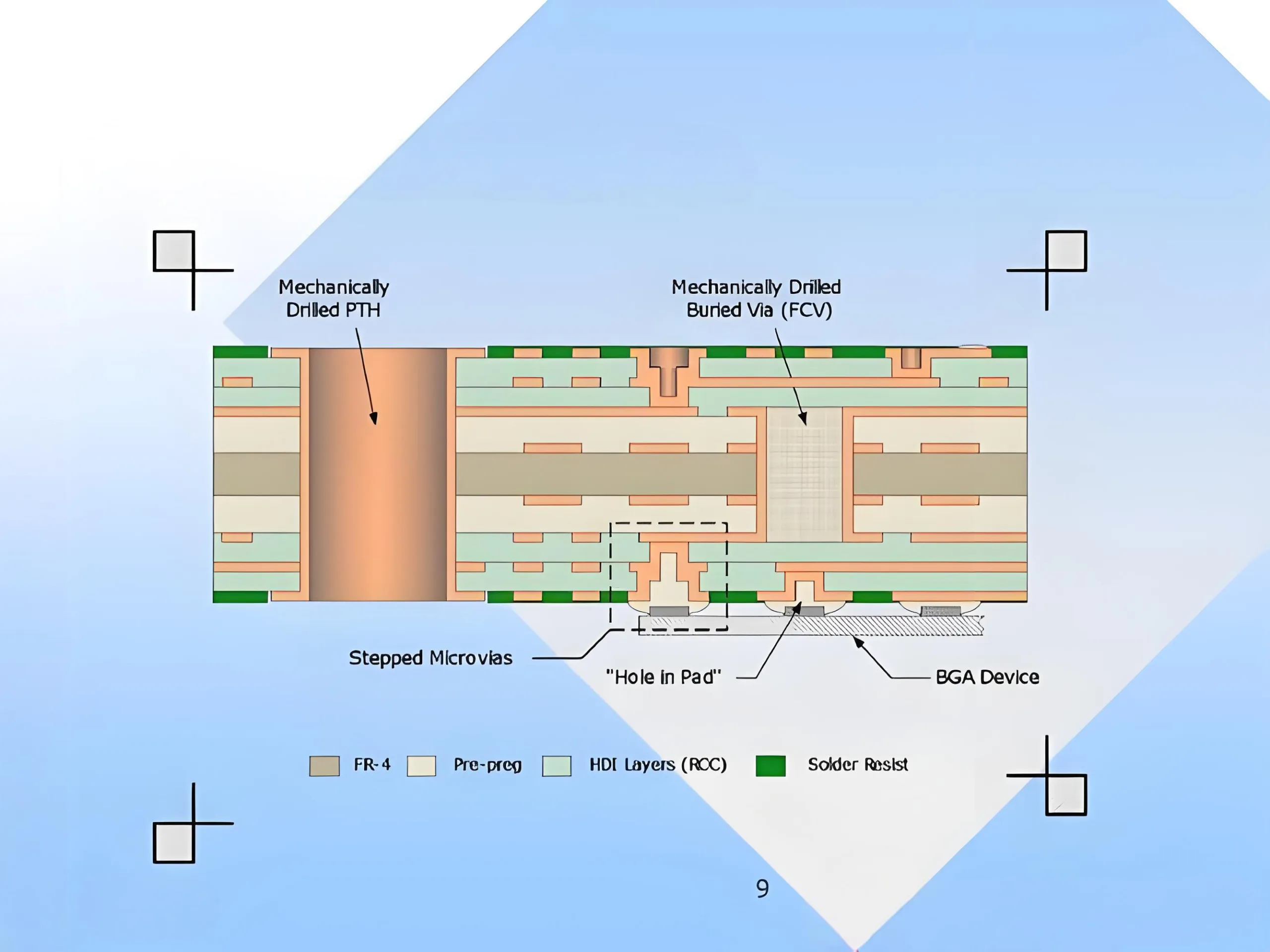

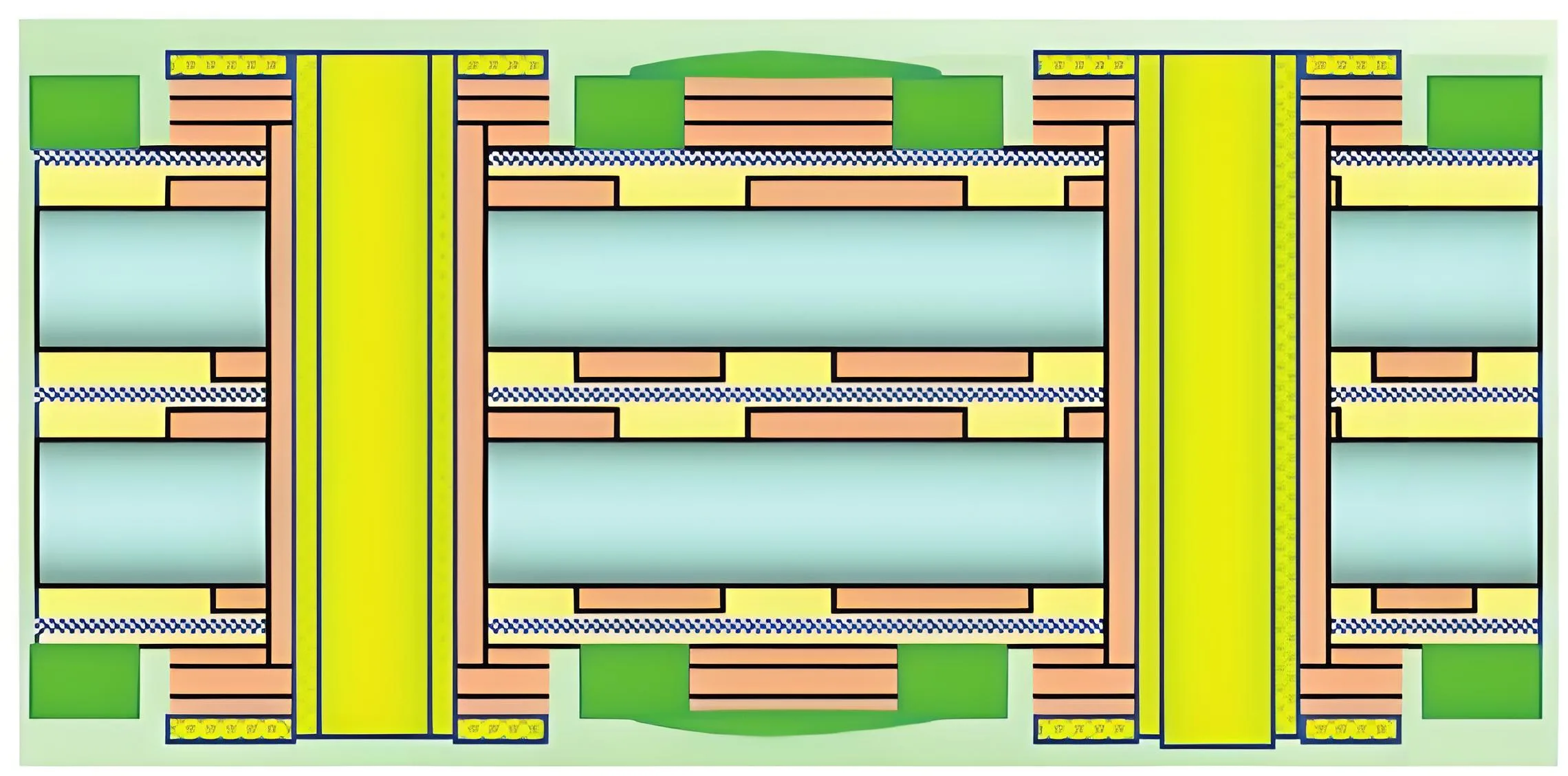

Multilayer PCB Technology: Supports 1-100 layer boards with interlayer alignment tolerance ≤15μm (Formula: δ = k√(n), where n = layer count, k = process constant).

-

Material Versatility: Rogers, FR4, aluminum-based PCBs, etc., meeting high-temperature demands (Tg 180°C-220°C) for automotive/aerospace applications.

2. 24-Hour Rapid PCB Prototyping Service

-

Global Fastest Delivery: 24 hours for 2-layer, 72 hours for 6-layer boards (industry average: 5-7 days).

-

Zero Startup Cost: Accepts orders from 1 piece with free DFM engineering review.

-

Success Story: Reduced new product development cycle by 60% for a German industrial client.

3. Laser Stencil Core Technology

-

Tension Control: 35±5 N/cm² (IPC-7525 compliant).

-

Nano Coating: Extends lifespan to 500,000 print cycles.

-

Smart Inspection: AOI systems detect aperture defects ≥15μm.

Scientific Manufacturing: Data-Driven PCB Process Innovation

Key Process Control Points (Real Data)

| Parameter | UGPCB Standard | Industry Benchmark |

|---|---|---|

| Copper Thickness Uniformity | ±1.5μm | ±5μm |

| Impedance Control | ±5% | ±10% |

| Hole Position Accuracy | ±25μm | ±50μm |

Defect Prevention (Solving User Pain Points)

-

Pad Overlap Issues: Dynamic drilling compensation algorithm used (Compensation Δd = 0.85 × Tool Wear Rate).

-

Silkscreen Imperfections: Enforced DFM rule checks (Font ≥40mil, Distance to Pad >10mil).

End-to-End Service: From Design to Delivery

File Specifications (Improving First-Pass Yield)

-

Accepts Gerber/ODB++/PCB source files.

-

Free one-stop solutions for common PCB design and manufacturing challenges. https://www.ugpcb.com/capacity/download/

Quality Certification System

-

Dual-Standard Inspection: UGPCB Level 2 + IPC Class 3.

-

Testing Equipment: Flying Probe Tester (0.1mm min. pitch), 3D X-ray (BGA inspection).

Take Action Now: Get Your Custom PCB Solution

Limited-Time Offer: Submit Gerber files → Receive Quote + Stencil Design within 24 hours.

-

Contact: sales@ugpcb.com / Online Quotation System

-

Key Solutions: PCB Bulk Manufacturing Supplier | Rush Prototype Service | High-Precision Stencil Fabrication

UGPCB LOGO

UGPCB LOGO

WeChat

Scan the QR Code with WeChat