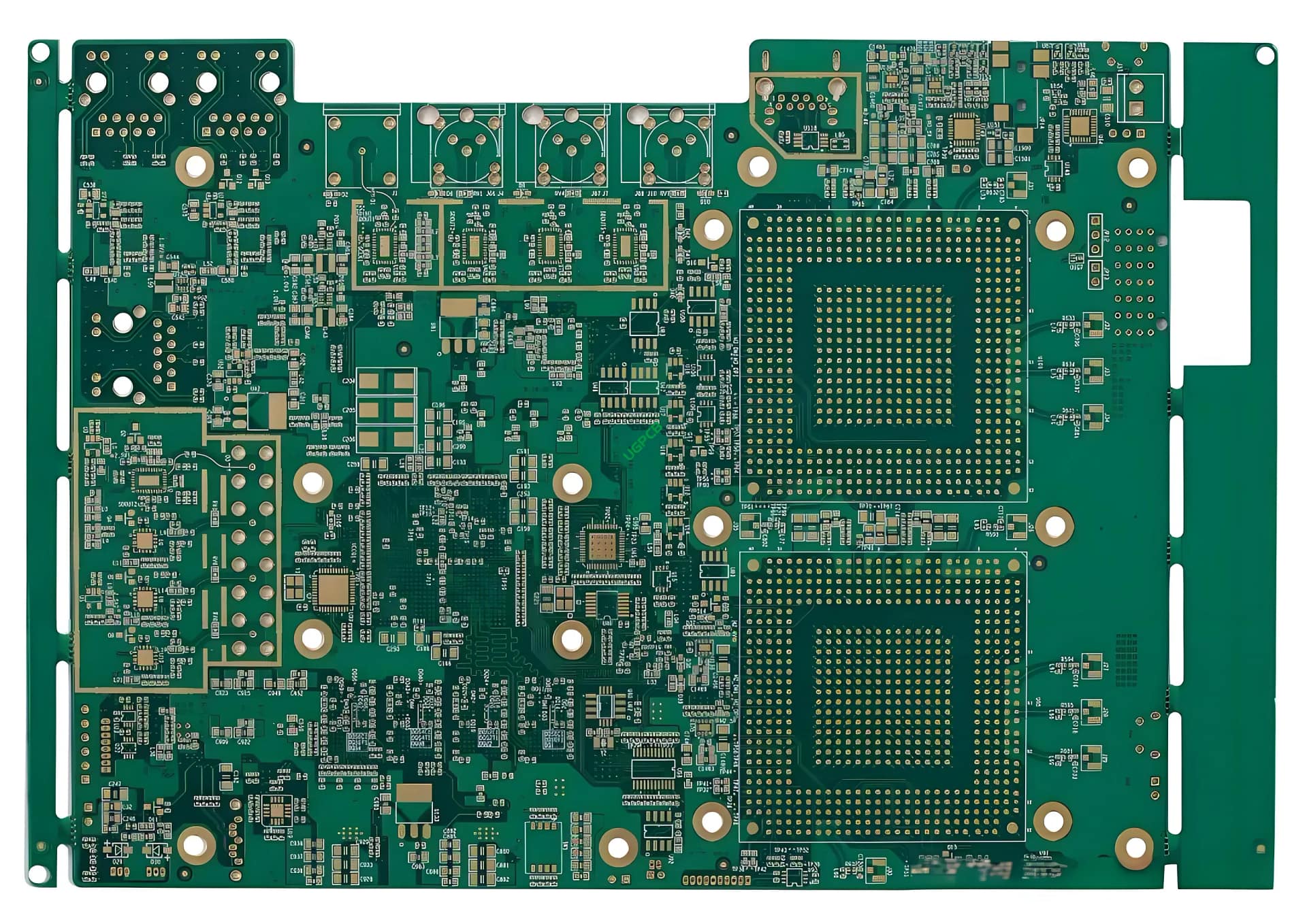

What is a BGA PCB?

A Ball Grid Array (BGA) Leiterplatte (Leiterplatte) is a type of Leiterplatte that features a grid of solder balls on its underside, used for connecting elektronische Komponenten to the board. This design allows for higher input/output connection density and improved electrical performance compared to traditional through-hole or surface-mount technology (SMT) Leiterplatten.

Entwurfsanforderungen

Designing a BGA PCB involves several key considerations:

- Material: Typically made from FR-4, a composite material known for its excellent electrical properties and affordability.

- Schichtzahl: Multilayer designs are common, providing more space for complex circuitry.

- Kupferdicke: Generally specified as 1/1OZ, balancing conductivity with cost-effectiveness.

- Oberflächenbehandlung: Often includes immersion gold to enhance solderability and protect against oxidation.

- Spur und Raum: Minimum trace and space are typically set at 4mil, allowing for fine details in the circuit design.

Wie funktioniert es?

The BGA PCB functions by providing a platform where electronic components can be mounted and interconnected using a grid of solder balls. These balls are aligned in a pattern on the underside of the board, corresponding to contact pads on the component. When heat is applied, the solder melts and creates a strong bond, ensuring reliable electrical connections.

Anwendungen

Due to their high density and reliability, BGA PCBs are widely used in various electronic products including:

- Computer motherboards

- High-performance servers

- Networking -Geräte

- Advanced consumer electronics like gaming consoles and smart devices

Einstufung

BGA PCBs can be classified based on several factors:

- Durch Material: Most commonly made from FR-4 due to its balance of cost, Stärke, und elektrische Eigenschaften.

- Für Schichtzahl: Can range from double-sided to multilayer configurations, Abhängig von der Komplexität der Schaltung.

- Durch Oberflächenbehandlung: Options include immersion gold, hasl, or organic solderability preservatives (OSP), each offering different levels of protection and solderability.

Materialien verwendet

The primary Materialien used in manufacturing BGA PCBs include:

- FR-4: Ein mit Glas verstärkter Epoxidlaminat, der eine hervorragende mechanische Festigkeit und thermische Stabilität bietet.

- Kupfer: Wird für die leitenden Schichten verwendet, mit der Dicke variiert basierend auf den Entwurfsanforderungen.

- Lötmaske: Typischerweise grün oder weiß, Es schützt die Kupferspuren vor Oxidation und versehentlichen Kurzkreisen.

- Immersionsgold: A surface treatment that improves solderability and protects against corrosion.

Leistungseigenschaften

Key performance attributes of a BGA PCB include:

- Hohe Dichte: Ermöglicht, dass mehr Komponenten in einen kleineren Bereich verpackt werden.

- Zuverlässigkeit: The use of solder balls reduces the risk of mechanical failure due to vibration or impact.

- Signalintegrität: Aufgrund kürzerer Signalwege und reduziertem Übersprechen verbessert.

Strukturkomposition

Strukturell, a BGA PCB comprises:

- Leitfähige Schichten: Aus Kupfer gemacht, in die gewünschten Schaltungsmuster eingraviert.

- Isolierschichten: Elektrische Shorts zwischen leitenden Schichten verhindern.

- Solder Balls: Arranged in a grid pattern on the underside of the board for component attachment.

Unterscheidungsmerkmale

Some notable features of a BGA PCB are:

- Feiner Tonhöhe: Allows for high-density interconnects, making it ideal for compact devices.

- Robustheit: The use of solder balls provides a strong mechanical bond between the board and components.

- Vielseitigkeit: Geeignet für eine Vielzahl von Anwendungen aufgrund anpassbarer Schichtzahlen und Materialauswahl.

Produktionsprozess

The manufacturing process of a BGA PCB involves several steps:

- Design und Layout: Verwenden von speziellen Software zum Erstellen des Schaltungsmusters.

- Materialvorbereitung: Schneiden von Grundmaterialien zu Größe und Reinigungsflächen.

- Laminierung: Stapeln und Binden einzelner Schichten unter Wärme und Druck.

- Radierung: Entfernen Sie überschüssiges Kupfer, um die gewünschten Schaltungswege zu bilden.

- Überzug: Hinzufügen einer dünnen Metallschicht zu Vias und exponierten Kupferbereichen.

- Lötmaskenanwendung: Anwenden der grünen oder weißen Beschichtung zum Schutz von Spuren.

- Oberflächenbehandlung: Applying immersion gold or other treatments for solderability.

- Endinspektion: Sicherstellung von Qualität und Funktionalität vor dem Versand gewährleisten.

Anwendungsfälle

Common scenarios where a BGA PCB might be employed include:

- High-density interconnect applications in mobile devices.

- Fortgeschrittene Kommunikationssysteme, die einen niedrigen Signalverlust erfordern.

- Tragbare medizinische Instrumente, die zuverlässige Leistung in harten Umgebungen benötigen.

- Automobilelektronik, die Robustheit und Langlebigkeit fordert.

Zusammenfassend, the BGA PCB represents a significant advancement in printed circuit board technology, offering unparalleled complexity and performance for modern electronic applications. Its design flexibility, combined with superior signal integrity and durability, makes it an essential component in the development of next-generation electronic products and beyond