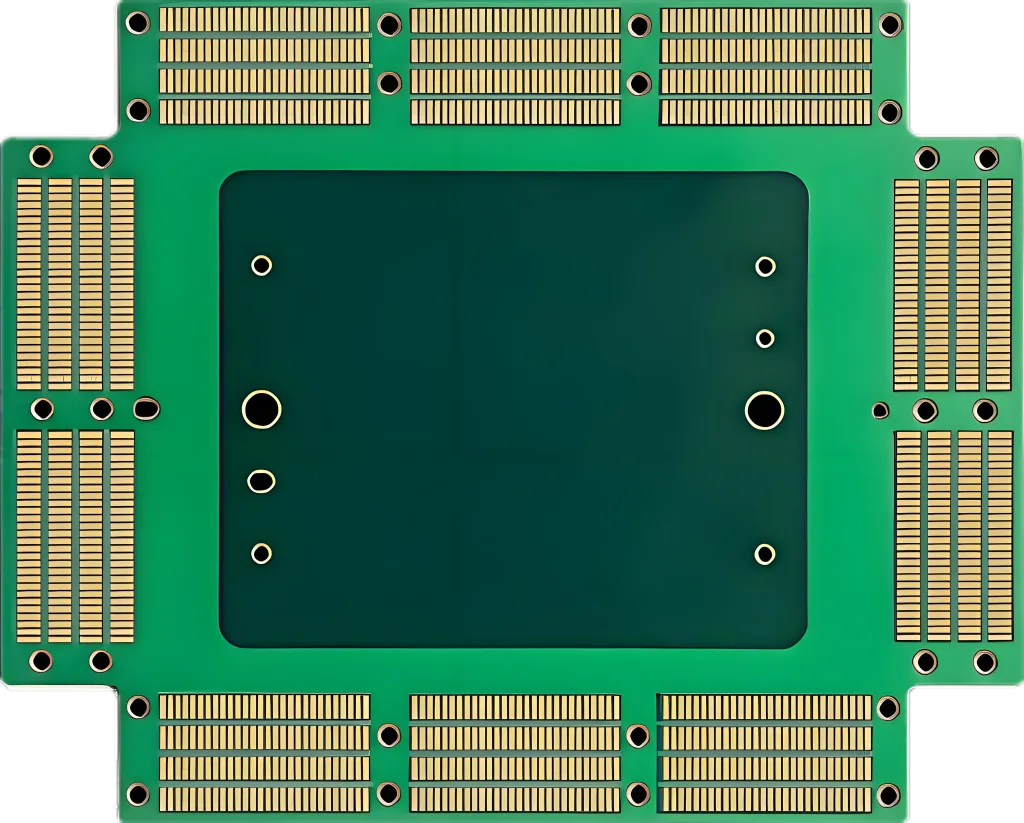

Introduction to the 58-Layer ATE Load PCB

The 58-layer ATE (Equipo de prueba automatizado) Load PCB is a high-density, multicapa placa de circuito impreso engineered for precision signal transmission and durability in demanding testing environments. Designed with advanced parameters, it ensures optimal performance in high-frequency and high-power applications.

Key Specifications

-

capas: 58

-

Dimensiones: 17.2″ x 17.8″

-

Espesor: 230 mil

-

Material: FR4 Tg185

-

Tamaño mínimo de agujeros: 5 mil

-

Espaciado BGA: 0.8 milímetros

-

Relación de aspecto: 23.4:1

-

Distancia de taladro a copper: 7 mil

-

POFV (Chapado sobre llenado a través de): Sí

-

Perforación trasera: No

-

Acabado superficial: ENEG+TG+ENIG

Design and Structural Features

Critical Design Considerations

-

High Layer Count: The 58-layer structure supports complex routing for high-density interconnects (IDH), minimizing signal loss.

-

Selección de material: FR4 Tg185 ensures thermal stability (up to 185°C glass transition temperature), critical for high-power applications.

-

Perforación de precisión: A 5 mil minimum hole size and 23.4:1 aspect ratio enable reliable microvia formation, essential for BGA (0.8 paso mm) component integration.

-

Integridad de señal: Controlled impedance and 7 mil drill-to-copper spacing reduce crosstalk and electromagnetic interference (EMI).

Unique Structural Advantages

-

Tecnología POFV: Enhances via reliability by filling and plating vias, improving thermal and mechanical performance.

-

ENEG+TG+ENIG Surface Finish: Combines electroless nickel electroless gold (Eneg) and immersion gold (ACEPTAR) for superior corrosion resistance and solderability.

Performance and Applications

Principios operativos

The PCB facilitates precise electrical signal routing across 58 capas, leveraging FR4 Tg185’s dielectric properties to maintain signal integrity. POFV ensures robust connections in high-stress environments, while the optimized aspect ratio supports stable high-frequency operations.

Métricas clave de rendimiento

-

Resistencia térmica: Withstands temperatures up to 185°C.

-

Mechanical Stability: High Tg material prevents delamination under thermal cycling.

-

Signal Speed: Low-loss dielectric material minimizes latency.

Casos de uso primarios

-

Equipo de prueba automatizado (ATE): Used in semiconductor testing systems for validating ICs and microprocessors.

-

Aeroespacial y defensa: Deployed in radar and communication systems requiring high reliability.

-

Telecomunicaciones: Supports 5G infrastructure and high-speed data transmission.

-

Electrónica automotriz: Integrated into ADAS (Advanced Driver Assistance Systems) and EV power modules.

Proceso de producción y garantía de calidad

Flujo de trabajo de fabricación

-

Preparación de material: FR4 Tg185 laminates are cut to 17.2″ x 17.8″ dimensions.

-

Perforación láser: Creates 5 mil microvias with a 23.4:1 relación de aspecto.

-

Plating and Filling: POFV technology applies copper plating to filled vias.

-

Layer Stackup: 58 layers are aligned and bonded under high pressure.

-

Acabado de superficies: ENEG+TG+ENIG coating is applied for corrosion protection.

-

Pruebas: Electrical continuity, impedancia, and thermal stress tests are performed.

Quality Control Standards

-

Clase IPC-6012 3: Ensures reliability for harsh environments.

-

Control de impedancia: ±10% tolerance maintained.

Summary of Advantages

-

Diseño de alta densidad: Supports complex circuitry in compact spaces.

-

Resiliencia térmica: FR4 Tg185 ensures stability under extreme conditions.

-

Precision Engineering: 5 mil holes and 0.8mm BGA spacing enable miniaturized component integration.

-

Aplicaciones versátiles: From semiconductor testing to 5G infrastructure.

This PCB combines cutting-edge design, rigorous manufacturing standards, and robust materials to meet the needs of mission-critical industries.