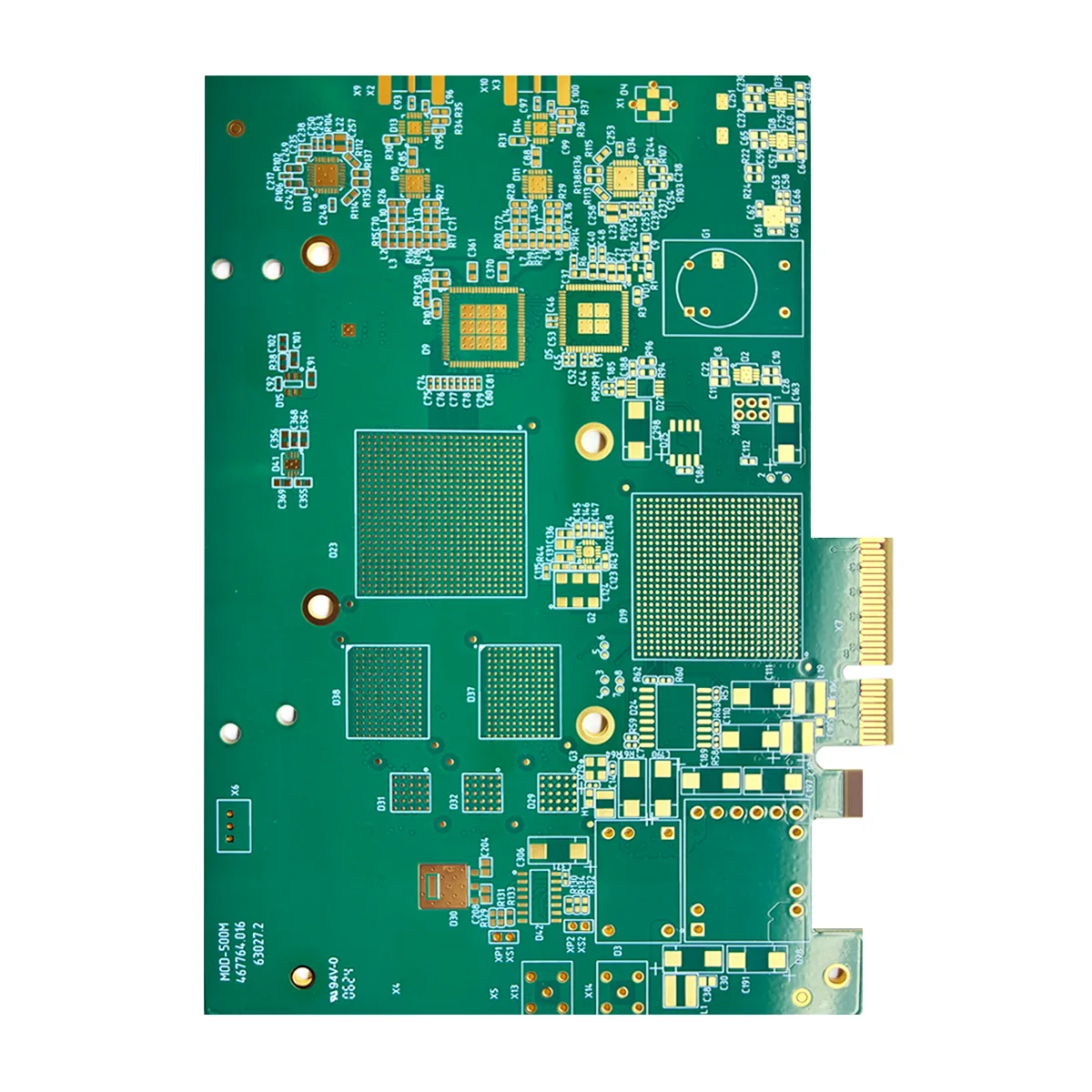

High-Performance 12-Layer ENIG + Gold Finger PCB Descripción general del producto

El 12-Layer Gold Finger PCB is a hallmark product in the high-end placa de circuito impreso industria, engineered specifically for electronic equipment demanding extreme reliability, stable electrical connections, and frequent plugging/unplugging cycles. UGPCB employs advanced manufacturing processes and premium materials (FR-4 TG170), combining 2μ” Electroless Nickel Immersion Gold (ACEPTAR) surface finish with 30μ” Hard Gold Finger Plating tecnología. We deliver a comprehensive high-reliability PCB solution for applications ranging from industrial controls to advanced communication systems.

Definición del producto

A Gold Finger PCB refers to a circuit board featuring a series of exposed, rectangular contact pads plated with thick gold (“fingers”) along one edge. These boards are designed for direct insertion into a matching connector slot, establishing a stable, pluggable connection for electrical signals and power between devices. Este producto es un 12-layer multilayer PCB with a standard thickness of 1.60milímetros, offering an optimal balance between complex circuit integration and mechanical robustness.

Consideraciones críticas de diseño

-

Gold Finger Area Design:

-

Chamfer (Bevel) Edge (Typically 20-45°): Facilitates smooth insertion into the connector—a critical aspect of Dedo de oro diseño de PCB.

-

Lead-in (Trace Fanout): Connections from the gold fingers to internal traces must have smooth curves, avoiding right angles to prevent stress concentration and plating cracks.

-

Solder Mask Clearance (Solder Mask Define): The gold finger area requires precise solder mask opening to ensure a clean, exposed plating surface.

-

-

Control de impedancia & Integridad de señal: As a 12-layer precision PCB, strict impedance control (p.ej., 50Ω single-ended, 100Ω differential) for high-speed signal layers is essential. Stack-up design must be optimized via simulation to minimize crosstalk.

-

Thermal & Reliability Management: High-Tg material, coupled with a well-designed via structure, ensures the high-layer-count PCB operates stably in elevated temperature environments. A través de los agujeros chapados (PTH) should be avoided at the root of gold fingers to prevent fluid entrapment and structural weakness.

How It Works & Estructura

This PCB facilitates complex circuit interconnections through its internal 12 conductive layers. The core functionality resides in the Hard Gold Plated Fingers. The durable 30-microinch gold plating provides excellent conductivity, oxidation resistance, and wear resistance. When the board is inserted into a backplane or card-edge connector, the gold fingers make tight, low-resistance electrical contact with the connector’s spring contacts, transmitting signals and power. The board core uses FR-4 TG170, providing solid mechanical support and electrical insulation.

Materiales núcleos & Presupuesto

-

Materia prima: FR-4 TG170. A high-performance epoxy glass laminate.

-

High Glass Transition Temperature (Tg ≥ 170°C): Significantly enhances the PCB’s mechanical stability and heat resistance under high-temperature operating conditions, preventing delamination and Z-axis expansion.

-

Superior Electrical Properties: Constante dieléctrica baja (Dk) and dissipation factor (df), suitable for mid-to-high frequency applications.

-

Alta resistencia mecánica: Ensures the 1.6mm thick PCB board resists bending and warping in mating/unmating and high-vibration environments.

-

-

Acabados superficiales:

-

Board Surface: Oro de inmersión de níquel químico (ACEPTAR, 2μ”): Provides a flat, coplanar surface for reliable soldering of fine-pitch components and offers excellent oxidation resistance.

-

Gold Fingers: Selective Electroplated Hard Gold (30μ”): High hardness, superior abrasion resistance, and extended mating cycle life, capable of withstanding 500+ insertion/withdrawal cycles with ease.

-

Características clave & Ventajas

-

Unmatched Reliability: FR-4 TG170 high-Tg material y 12-layer precision lamination ensure long-term stability in harsh operating conditions.

-

Extended Mating Cycle Life: 30μ” thick hard gold fingers far exceed standard plating thickness, offering exceptional wear resistance—the ideal choice for high-durability plug-in PCBs.

-

Excelente integridad de la señal: The multilayer design provides uninterrupted reference planes for high-speed signals, and controlled impedance guarantees signal quality.

-

Robust Thermal & Mechanical Performance: The 1.60mm standard thickness combined with high-Tg material delivers superior rigidity, gestión térmica, and dimensional stability.

-

Comprehensive High-End Solution: De multicapa fabricación de PCB a specialty surface finishing (ACEPTAR + Selective Gold), UGPCB provides full-process control, ensuring consistent, high-quality results.

Manufacturing Process Flow

Panelization → Inner Layer Imaging → Lamination (12-Capa) → Drilling → Desmear & Electroless Copper Deposition → Outer Layer Imaging → Pattern Plating (for Hard Gold Fingers) → Etching → Solder Mask Application → ENIG Surface Finish → Gold Finger Beveling → Electrical Test (Sonda voladora / Fixture) → Inspección óptica final automatizada (AOI) → Embalaje.

Aplicaciones primarias & Casos de uso

This product is the core component of high-end electronic devices requiring direct board-to-board plug connections o integration into backplane systems.

-

Industrial Control Systems: PLC modules, industrial computer motherboards, servo drives, I/O interface cards.

-

Telecomunicaciones & Networking Equipment: Router/switch line cards, optical transceiver modules, baseband processing units.

-

Electrónica médica: Data acquisition and processing boards for advanced medical imaging systems (p.ej., Escáneres CT, ultrasound machines).

-

Prueba & Measurement Instruments: Plug-in modules for high-end oscilloscopes, spectrum analyzers, and Automated Test Equipment (ATE).

-

Aeroespacial & Defense Electronics: Mission-critical avionics systems and radar signal processing modules where reliability is paramount.

Scientific Product Classification

-

Por recuento de capas: High-Layer-Count / Multilayer Circuit Board (≥8 layers, específicamente 12 capas).

-

By Special Feature/Process: Dedo de oro (Gold Edge Connector) tarjeta de circuito impreso, Mixed Surface Finish PCB (ACEPTAR + Selective Hard Gold).

-

By Material Property: Tg alta (TG170) tarjeta de circuito impreso, FR-4 Series PCB.

-

By Application Grade: Industrial-Grade PCB, Telecom-Grade PCB, High-Reliability PCB.

Why Choose UGPCB’s 12-Layer Gold Finger PCB?

We understand that a reliable Gold Finger PCB is the foundation of your high-end equipment’s stable operation. Leveraging deep expertise in multicapa fabricación de PCB y specialty surface finish processes, UGPCB guarantees that every board delivered meets military-grade reliability standards with commercial-grade delivery efficiency. We provide not just a product, but a customized PCB solution.

Contact our technical sales team today to discuss your project requirements, receive a detailed quote, and qualify for a free design-for-manufacturability (DFM) revisar and sample program. Partner with UGPCB for your most demanding 12 layer circuit board aplicaciones.