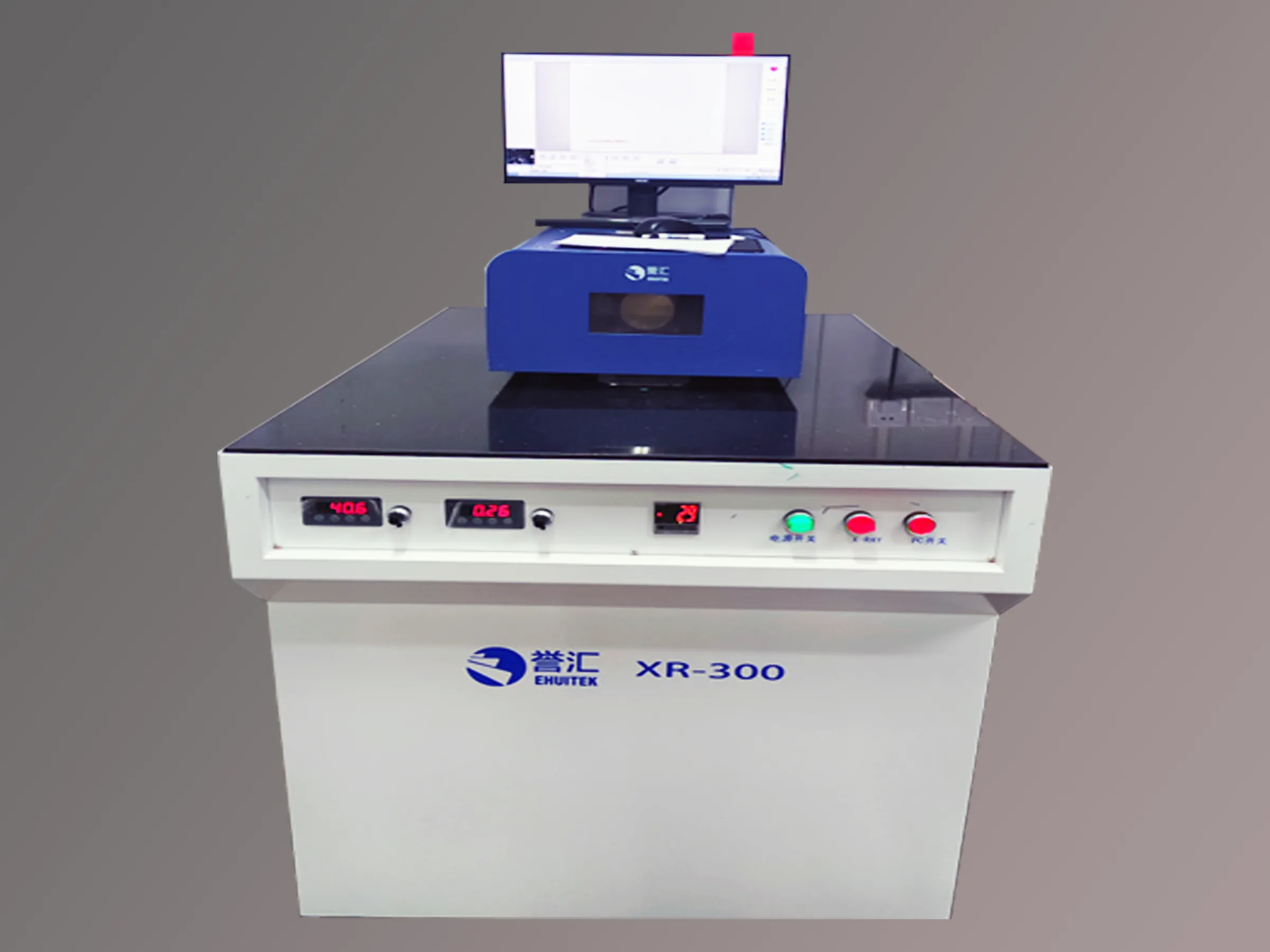

UGPCB’s YuHui XR-300 Inner Layer X-Ray Drilling System: Setting New Standards in Precision PCB Manufacturing

Dans le circuit imprimé (PCB) et assemblage de circuits imprimés (PCB) manufacturing industry, processing precision and quality reliability are core indicators of a manufacturer’s professional capability. UGPCB, a leading PCB and Fabricant de PCBA, has further strengthened its technological edge in precision manufacturing by introducing the industry-leading YuHui XR-300 Inner Layer X-Ray Drilling Inspection System.

Challenges in PCB Quality Control for High-Density Interconnects

With the rapid advancement of artificial intelligence technology, computational power demands have exploded, placing higher requirements on the core hardware support for the data communication industry – PCB substrates. The need for high-frequency, high-speed signal transmission in AI servers necessitates excellent signal integrity in PCBs, giving rise to high-layer count designs. To accommodate high chip integration density and complex interconnect structures, Conceptions de PCB extensively utilize advanced processes like back drilling, blind vias, and stacked vias.

Cependant, these advanced designs and processes introduce new quality challenges. Par exemple, back-drilled micro-vias often have diameters of just 0.20mm to 0.80mm, yet depths can reach 6mm, with maximum aspect ratios as high as 15. At this scale, ensuring drills reach their precise design locations and correctly connect to specific inner layers presents a significant challenge for PCB manufacturing.

Technical Advantages of the YuHui XR-300 Inner Layer X-Ray Drilling Inspection System

The YuHui XR-300 Inner Layer X-Ray Inspection System integrated by UGPCB incorporates multiple cutting-edge technologies, achieving major breakthroughs in PCB quality control.

High-Precision Imaging and Measurement Capabilities

The YuHui XR-300 utilizes an imported sealed micro-focus X-ray tube and a high-quality imaging system, achieving sub-micron resolution. The system offers a measurement accuracy of up to 30μm and a resolution of 17-25 lp/mm, enabling clear capture of minute structures within PCB inner layers. Compared to traditional X-ray systems, the YuHui XR-300 provides a fluoroscopic magnification range of 8X to 64X, allowing operators to observe and measure key parameters in real-time, including center position, point-to-point distance, and circular area.

Innovative Non-Destructive Testing Technology

Using X-ray triangulation imaging methods and algorithms, the YuHui XR-300 precisely determines the end position of back-drilled holes, ensuring drills achieve the intended depth and connect to the specific target layer. A key advantage is its ability to measure the distance between a drill hole and an inner layer copper plane, enabling engineers to directly determine if the hole is correctly positioned and the required remaining drill depth.

Unlike traditional destructive testing methods, X-ray inspection identifies internal defects with high resolution without cutting PCB samples, significantly improving failure analysis efficiency. This non-destructive approach avoids introducing new defects from external stress during sample preparation, ensuring accurate assessment results.

Exceptional Performance in Multilayer PCB Inspection

Designed to handle the complex structures of modern PCBs, the YuHui XR-300 can inspect boards with 26 layers or more, supporting configurations with copper weights from 1/3 oz to 20 once. This capability perfectly meets the quality inspection demands of today’s high-layer count PCBs, especially regarding signal integrity requirements for high-frequency, PCB à grande vitesse.

Key Applications of the YuHui XR-300 in the PCB Manufacturing Process

PCB Drilling Process Quality Control

In PCB manufacturing, mechanical drilling quality directly impacts subsequent plating and the reliability of final electronic products. Based on X-ray micro-CT technology, the YuHui XR-300 acquires high-resolution data of a PCB sample’s 3D structure, enabling measurement of drilling accuracy within the same scanned dataset used to reconstruct the 3D model.

Using the YuHui XR-300, UGPCB engineers can accurately evaluate critical parameters like hole straightness error, cylindricity error, and 3D surface roughness, enabling comprehensive assessment of drilling quality. Compared to contact measurement methods, micro-CT technology not only captures complete sample data but also avoids potential alteration of the sample’s actual morphology from probe pressure.

Precise Back Drilling Quality Assessment

Back drilling is a critical process for addressing signal integrity issues, but drilling too deep or misalignment can affect final product performance. The YuHui XR-300 can inspect for over-drilled back holes without damaging the sample, while simultaneously evaluating back drill alignment and measuring stub length, ensuring the back drilling process meets PCB design standards.

Stacked Via Defect and Delamination Inspection

Addressing the extensive use of stacked via processes in PCB design, the YuHui XR-300 performs high-resolution, non-destructive inspection of internal stacked via defects. En outre, the system comprehensively examines PCBs for internal delamination, precisely locates delamination areas, analyzes affected zones, and measures delamination area, providing reliable data support for process improvement.

Value of the YuHui XR-300’s Technical Breakthrough for PCBA Assembly

During the PCBA assembly stage, the YuHui XR-300 plays a vital role. The system can inspect for BGA solder ball voids, power component solder voids, and the integrity of solder balls in ball grid array packages, including defects such as solder ball deformation, solder cracks, joints de soudure à froid, solder ball shorts, and bubbles.

For chip-scale packages and PCBA with high-density interconnects, the high-resolution imaging capability of the YuHui XR-300 can identify micron-level defects, such as open circuits caused by broken coil solder joints, ensuring PCBA assembly reliability. The system’s equipped X-Plane image layering technology easily facilitates inspection of complex PCBA layouts, like double-sided boards and Package-on-Package structures, greatly enhancing the efficiency and accuracy of PCBA quality control.

Advanced Image Processing Technology Integrated with Artificial Intelligence

The YuHui XR-300 integrates AI-based reconstruction technology, enabling up to 10x efficiency gains in specific semi-repetitive and repetitive sample workflows or delivering superior image quality. This intelligent image processing capability allows UGPCB to rapidly identify minute defects within vast amounts of inspection data, substantially improving the efficiency and accuracy of product quality control.

The system’s DeepRecon Pro technology employs AI algorithms to enhance image quality while reducing scan times, providing robust technical support for UGPCB’s high-precision PCB manufacturing and PCBA assembly.

Protective Design Ensuring Operational Safety

Regarding the safety performance of the X-ray equipment, the YuHui XR-300 incorporates multiple protective features, including a sealed micro-focus X-ray tube, a semi-enclosed lead shielding structure, and double-layer lead rubber protective curtains. System radiation leakage is controlled at ≤0.5μSV/h, significantly below safety standards, ensuring safe and reliable operation for personnel.

UGPCB: Committed to Delivering Excellent PCB and PCBA Solutions

By introducing equipment like the YuHui XR-300 Inner Layer X-Ray Inspection System, UGPCB further solidifies its technological leadership in high-precision PCB manufacturing and reliable PCBA assembly. This investment underscores UGPCB’s commitment to quality control and demonstrates its dedication to continuous innovation and customer service.

UGPCB’s YuHui XR-300 system meets the verification needs of various complex PCB designs, including impedance-controlled PCBs, PCB à haute vitesse à haute fréquence, high-density interconnect PCBs, et PCB rigides-flexibles. Whether for communication equipment demanding extreme PCB drilling accuracy or medical electronics with stringent PCBA soldering quality standards, UGPCB delivers reliable solutions.

In the increasingly competitive PCB and PCBA market, quality and reliability are key to earning customer trust. Leveraging advanced production and inspection equipment like the YuHui XR-300, UGPCB achieves precise quality control, offering high-reliability PCB manufacturing and PCBA assembly services, making it the partner of choice for industry experts and procurement professionals.