UN circuito più sottile di carta è ora un campo di battaglia critico nella competizione tecnologica globale. Dai server AI ai veicoli intelligenti, Le sue prestazioni determinano direttamente il successo o il fallimento dei prodotti elettronici.

Al laboratorio di test di UGPCB, Gli ingegneri collocano un server AI di recente prodotto PCB in un ambiente freddo estremo di -55 ° C, quindi trasferiscilo rapidamente su una camera ad alta temperatura di 125 ° C dopo 30 secondi. Questo duro test del ciclo si ripete 1,000 TEMPI-Garantire che ogni circuito a livello di micron mantiene la stabilità del segnale in condizioni estreme.

“Our project nearly missed its deadline due to PCB signal interference!” lamented a tech company R&D regista. Con il boom di calcolo dell'IA e la rivoluzione dell'architettura elettronica per veicoli intelligenti, La produzione di PCB di fascia alta sta subendo una trasformazione tecnologica senza precedenti e competizione di capacità.

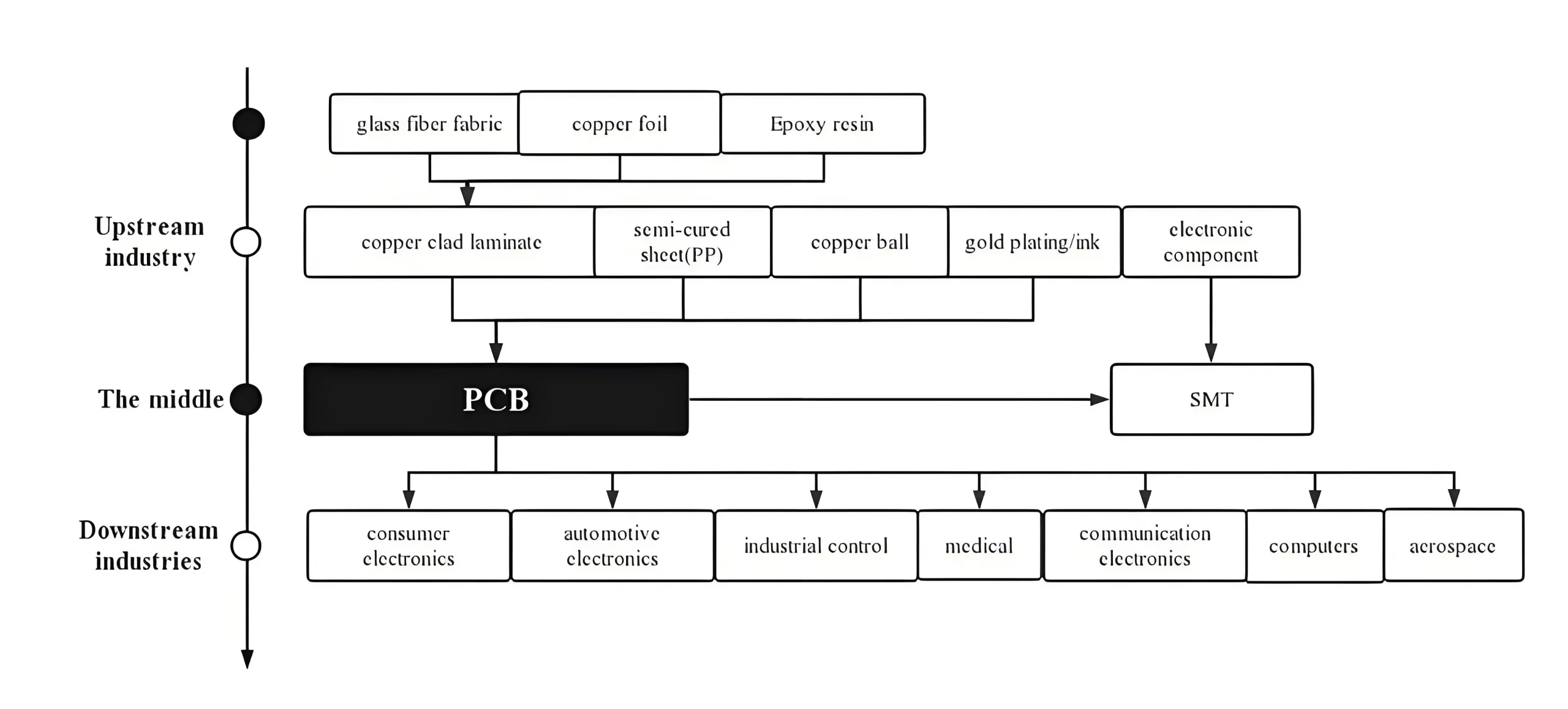

01 Analisi della catena del settore: Il sistema circolatorio di produzione di PCB

PCB, hailed as the “Mother of Electronics,” form the core skeleton of nearly all electronic devices. Come piattaforma di base per i componenti, Abilitano la connettività elettrica critica. La loro qualità determina direttamente l'affidabilità del prodotto finale, durata, e competitività del mercato.

A monte: The “Three Kingdoms” Battle in Raw Materials

Le materie prime costituiscono 60% di costi di PCB, con laminato rivestito in rame (CCL) Solo tenendo conto 27.31%. CCL è un materiale composito composto:

-

Lamina di rame (42.1% del costo CCL): I server di intelligenza artificiale guidano la domanda di pellicola a bassa decisione (PURITÀ ≥99,99%)

-

Tessuto elettronico in fibra di vetro (~ 27% costo): 5Stazioni base G. & I server AI richiedono tessuto in vetro a basso DK

-

Resina sintetica: La domanda di resina a base d'acqua cresce 15% Yoy, Spinto da UE ROHS & Gli standard ecologici cinesi

Midstream: Ingegneria di precisione nella fabbricazione di PCB

PCB Manufacturing Mescola arte e ingegneria. A 8 strati all'avanguardia 3+N+3 Schede HDI ottenere 2,5 mil/2,5 mil (≈0.063mm) larghezza della linea/precisione di spaziatura, con precisione di perforazione laser entro ± 25μm.

Brive di processo chiave:

-

Ottimizzazione in pila: Riduce il segnali di crosstalk di 30% tramite simulazione di impedenza

-

Microvia scaglionate: Raggiungere 15:1 Rapporti di aspetto per il routing ad alta densità

-

24-Test di invecchiamento dell'ora: Convalida l'affidabilità a 85 ° C/85% di stress RH

I dati di Prismark mostrano 2023-2028 crescita: 18+ schede a livello (9% CAGR), China HDI (6% CAGR, leader globale), Substrati dei circuiti integrati (7% CAGR), PCB flessibili (4% CAGR).

A valle: Crescita esplosiva nelle applicazioni PCB

AI Computing e EV intelligenti stanno rimodellando la domanda di PCB:

-

Server AI: Guida volumi/prezzi PCB più alti; aumento della densità di calcolo per rack + controllo impedenza rigoroso per Patatine ai

-

Nuovi veicoli energetici (Nevs):

-

Contenuto PCB 4-5x Veicoli tradizionali

-

800Le piattaforme V richiedono 40% Resistenza a tensione più elevata

-

I sensori ADAS aumentano la domanda di PCB ad alta frequenza

-

-

Elettronica medica: I dispositivi impiantabili richiedono contaminazione ionica ≤1,56μg/cm² (NaCl Eq.), superando di gran lunga gli standard dei consumatori.

02 Groucce tecnologiche: Tre battaglie critiche nella produzione avanzata di PCB

Rivoluzione del materiale PCB: Dalla fisica di base agli effetti quantistici

Le applicazioni ad alta frequenza richiedono nuovi materiali. 5Le stazioni base G richiedono un controllo di impedenza ± 7% (>10GHz), Spurming Resin Resin R&D:

Formula di scienze dei materiali: Df = ε” / ε’

(Fattore di dissipazione = perdita dielettrica / Permittività)

I materiali a basso DF/DK sono fondamentali. Parametri di riferimento del settore come PTFE modificato (Df<0.001) e resine di idrocarburi (DF = 0,001-0,002) ridurre la perdita del segnale MMWAVE di Over 60%.

Innovazione del processo PCB: Sfide a livello di micron

Alla fabbrica intelligente di UGPCB, trapani laser processo a 8 strati 3+n+3 hdi a 300 buchi/secondo. Progressi chiave:

-

Interconnessione di qualsiasi strato: Abilita 15:1 Microvia di proporzioni

-

Controllo dell'impedenza: ± 5% tolleranza (vs. ± 7% per il radar automobilistico)

-

Tecnologia rigida-flex: Sopporta >100,000 Piegare i cicli

Allineamento dello strato entro 12 μm (1/6 Capelli umani) Garantisce il vuoto BGA <25% (Classe IPC-A-610 3), prevenire i guasti alla saldatura dei chip.

Evoluzione dell'ispezione: Dalla post-produzione alla previsione in tempo reale

Ispezione a raggi X automatizzata con AI (Assi) aumenta la velocità di ispezione BGA 5x, Ridurre le mancate <0.1%. Analisi di fallimento avanzata:

-

Ispezione visiva (100X microscopio)

-

Test elettrici (Analizzatore di rete)

-

Radiografia/sezione trasversale (SEM/EDS)

-

Imaging termico (Rilevamento del punto caldo)

I PCB di livello automobilistico richiedono -40 ° C ~ 125 ° C Ciclismo termico (1,000 cicli) con <0.01% Drift di impedenza per le applicazioni BMS.

03 Competizione globale: Turni di capacità & Posizionamento tecnologico

Dinamica regionale: Dominanza Asia-Pacifico

2025 Paesaggio PCB: “East-led, multi-polar growth”:

-

Cina: 53% capacità globale (Prismark)

-

Sud -est asiatico: 20% Crescita teatrale (Thailandia, Vietnam)

-

U.S.A.: Subsidies via “Circuit Board Protection Act 2025”

L'ascesa PCB di fascia alta della Cina

Mentre la Cina è in volume, La sua produzione rimane di livello medio-basso (81% schede rigide). Le principali aziende stanno rompendo le barriere:

-

Circuiti Shennan: Substrati FCBGA per GPU NVIDIA

-

UGPCB: PCB radar MMWAVE certificato per automobili

-

Kinwong Electronics: PCB di comunicazione satellitare SpaceX

Ricerca Nester progetta il mercato globale del PCB che raggiunge $ 155,38 miliardi di 2037, con la quota di fascia alta della Cina potenzialmente in aumento 15% A 35%.

04 Campi di battaglia futuri: AI & Crescita dell'unità di elettrificazione

Hai calcolo: The “Dimensional Leap” for PCBs

AI Infrastructure Investment Reshapes PCB Tech:

-

Schede server AI: >20 Gli strati ora comprendono 60%

-

Substrati HBM: Larghezza della linea <8μm

-

PCB del modulo ottico: 80% Adozione di materiale a bassa perdita

AI Server PCB Market CAGR: 16% (Gelo & Sullivan). I telefoni AI usano 30% più strati e 15 FPCS/unità, accelerare l'adozione di HDI.

Rivoluzione EV: Reengineering the Automotive “Heart”

NEV Electronics Crea nuovi standard PCB automobilistici:

-

Controller di dominio: 8-12 strato dominanza HDI

-

Schede lidar: Materiali PTFE ad alta frequenza

-

800Piattaforme V.: L'isolamento resiste a ≥3kv

2025 Vendite NEV: ~ 15 m unità. Valore PCB/veicolo 4x Ice Auto. BMS PCBS richiede 0.01% stabilità dell'impedenza (-40° C ~ 125 ° C.).

Produzione sostenibile: L'imperativo di conformità

Mandato di regolamento EPR dell'UE:

-

100% Saldatura senza piombo da 2026

-

95% tasso di riciclaggio del rame

-

≥30% di resine a base biologica

Gli standard di emissione della Cina richiedono 40% Riduzione del COV, spingere l'adozione dell'inchiostro a base d'acqua nella stampa PCB da 35% A 65% di 2027.

05 Conclusione: Posizionamento strategico & Scelte

L'industria globale dei PCB sta subendo una profonda trasformazione. Mordor Intelligence prevede una crescita del mercato da $ 84,24 miliardi (2025) a $ 106,85b (2030) A 4.87% CAGR. Opportunità chiave:

-

Capacità di fascia alta: 18+ schede a livello (9% CAGR), Carenza di substrato IC (30%)

-

Shift regionale: 25% Costi di installazione inferiori nel sud -est asiatico

-

Innovazione materiale: Materiali DK/DF bassi (40% YOY richiede crescita)

Nota: I dati presentati in questo documento provengono dagli ultimi rapporti di istituzioni autorevoli tra cui Prismark, IPC, e gelo & Sullivan. Tutti i parametri tecnici sono stati validati attraverso test rigorosi condotti in laboratori accreditati con CNA. Gli standard di processo aderiscono rigorosamente alle attuali specifiche dell'edizione come IPC-6012EM* e IPC-2221B.