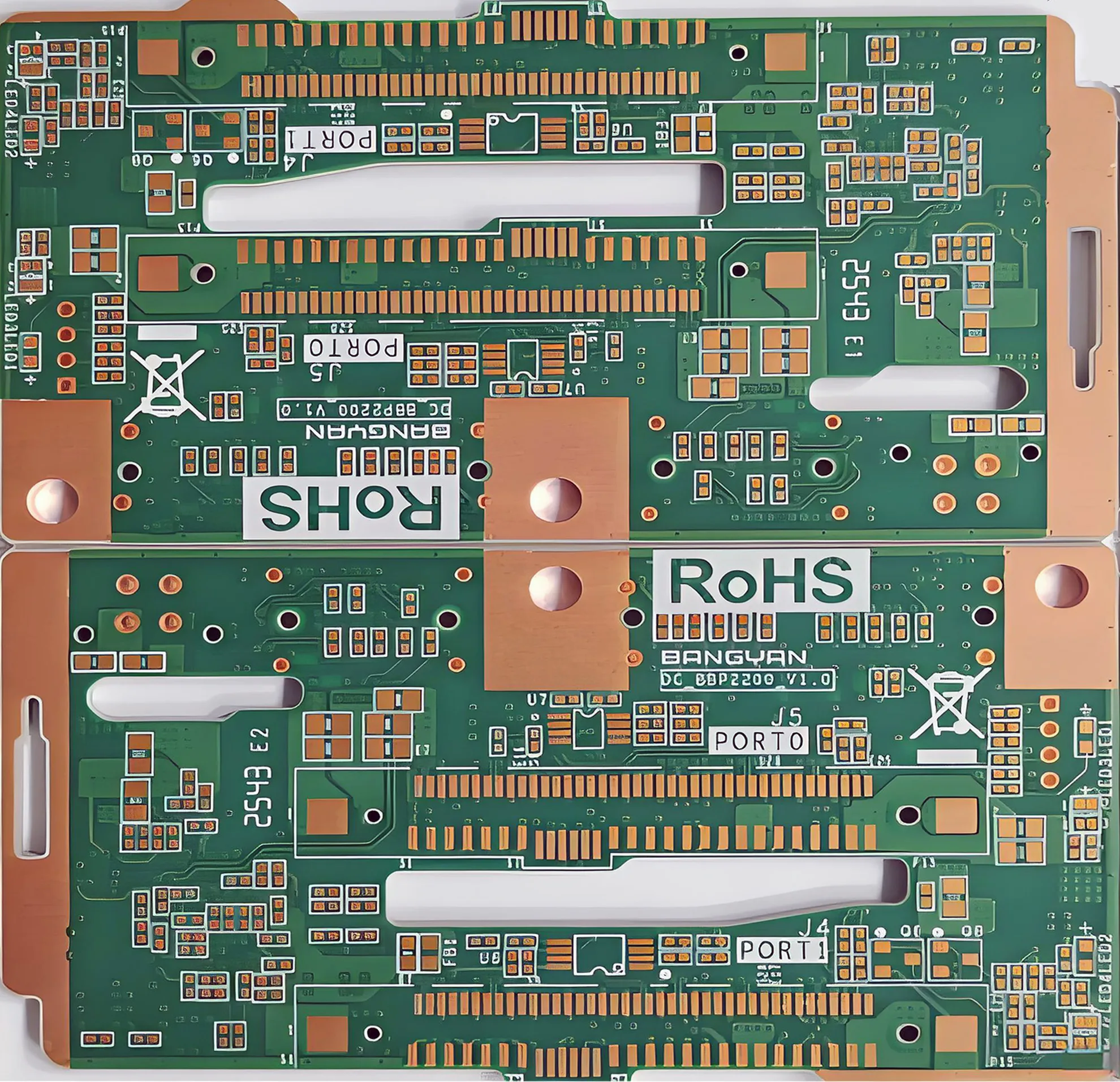

Professional Product Overview: The 12-Layer High-Speed, High-Density PCB

In the era of high-speed data transmission and complex system integration, conventional printed circuit boards (PCB) fall short of meeting the performance demands of advanced electronics. IL 12-layer high-speed, PCB ad alta densità is the engineered solution. Featuring up to 12 precisely aligned conductive layers, it enables intricate interconnections and efficient signal transmission within a compact footprint, serving as the “central nervous system” for high-end networking gear, data center servers, calcolo ad alte prestazioni (HPC), and AI hardware.

As an expert Produttore di PCB E Fornitore di PCB, UGPCB leverages advanced processes to deliver reliable 12-strato Scheda PCB produzione, ensuring your products maintain a competitive performance edge.

In-Depth Parameter Analysis: The Foundation of Performance

The capability of a high-quality circuito stampato multistrato is defined by its specifications. Below is an analysis of this product’s core parameters:

-

Conta dei strati & Stack-up: 12 strati. Questo multilayer PCB design offers superior signal integrity (E), Integrità del potere (PI), and EMC performance compared to boards with fewer layers. It allows for dedicated power and ground planes, providing clear return paths for high-speed signals.

-

Spessore della scheda & Tolleranza: 2.4mm ±10%. This robust thickness offers excellent mechanical strength for backplanes and large-form-factor applications, ensuring reliability during mating and installation. The tight tolerance guarantees consistency in assembly.

-

Finished Copper Weight: Unique distribution:

1/1/1/1/1/2/2/1/1/1/1/1 oz. This indicates that the inner layers (L6 & L7) utilize 2oz heavy copper, designed specifically for high-current power delivery. The outer and other signal layers use 1oz copper, optimized for fine-line etching. This hybrid construction is a hallmark of Alta affidabilità Fabbricazione di PCB. -

Critical Process Capabilities:

-

Minimum Drilled Hole Size: 0.2mm. Supports high-density BGA fan-out, enhancing routing flexibility.

-

Minimum Line Width/Space: 0.076mm / 0.09mm (3mil / 3.5mil). Raggiunge Interconnessione ad alta densità (ISU)-level routing, essential for high-speed signal propagation.

-

-

Finitura superficiale: OSP (Conservante organico di saldabilità). Compatible with both leaded and lead-free soldering, it protects copper pads from oxidation, offers excellent surface planarity, and is cost-effective—ideal for boards with dense SMT componenti.

Materiali core & Key Technologies: Enabling Superior Signal Integrity

-

High-Performance Laminate: Utilizes Nanya NY6300S high-speed laminate. Its high glass transition temperature (Tg >150° C.) ensures dimensional stability and reliability during high-temperature reflow soldering. Its optimized dielectric constant (Non so) and dissipation factor (Df) significantly reduce signal loss at high frequencies, forming the material foundation for PCB ad alta frequenza.

-

Advanced Copper Foil: Employs RTF (Reverse Treated Foil) rame. Compared to standard electrodeposited (Ed) foil, RTF foil features a smoother, low-profile surface on the treated side. This reduces signal loss due to the “skin effect” at high frequencies, critically enhancing the performance of differential signals exceeding 10 GBPS.

-

Critical Process: Controlled-Depth Drilling (Foratura posteriore): In 12-layer or higher PCB multistrato, the unused portion (stub) of a through-hole via can cause significant signal reflection, degrading integrity. IL back drilling process precisely removes this non-functional via stub, eliminating its negative impact—a key technology for high-speed multilayer PCB prestazione.

Flusso di produzione & Garanzia di qualità

UGPCB 12-processo di produzione di PCB a strati strictly adheres to Standard IPC and includes Progettazione per la produzione (DFM) review, inner layer imaging, laminazione, perforazione (including back drilling), placcatura, outer layer imaging, solder mask application, finitura superficiale (OSP), instradamento, electrical testing, e ispezione finale. Each stage is supported by precision measurement equipment (AOI, Impedance Testing, Flying Probe Test), ensuring every circuito delivered meets design specifications and our high-quality standards.

Applicazioni tipiche & Product Classification

This high-performance Scheda PCB is designed for demanding electrical environments and complex systems, primarily used in:

-

High-End Network & Attrezzatura di comunicazione: Core motherboards for 400G/800G optical modules, router di fascia alta, e interruttori.

-

Data Center & Cloud computing: Server motherboards, accelerator cards, backplane di archiviazione.

-

Calcolo ad alte prestazioni: Workstation motherboards, GPU computing cards, AI accelerator hardware.

-

Prova avanzata & Strumenti di misura: Internal boards for instruments processing very high-frequency signals.

Scientific Product Classification:

-

Per conteggio strati: PCB multistrato (>8 strati)

-

By Technology Type: PCB ad alta velocità/alta frequenza, PCB HDI, PCB di rame pesante (partial)

-

Per applicazione: Telecom Infrastructure PCB, Data Center/Server PCB

Why Choose UGPCB for Your 12-Layer High-Speed PCB?

-

Competenza tecnica: Proven mastery of back drilling E RTF copper foil application to tackle high-speed design challenges.

-

Produzione di precisione: Capable of 3/3.5 mil line/space, meeting stringent high-density interconnect requirements.

-

Material Integrity: Core use of reputable high-speed laminates like Nanya NY6300S ensures foundational performance.

-

Supporto per il design: Expert Progettazione di circuiti stampati E DFM review services to de-risk your project from the start.

-

Consistent Quality: A fully controlled Produzione di PCB and inspection system delivers reliable products you can trust.

Ready to elevate your hardware? Contact UGPCB’s engineers for a free PCB quote E Analisi DFM on your next 12-layer high-speed board project.