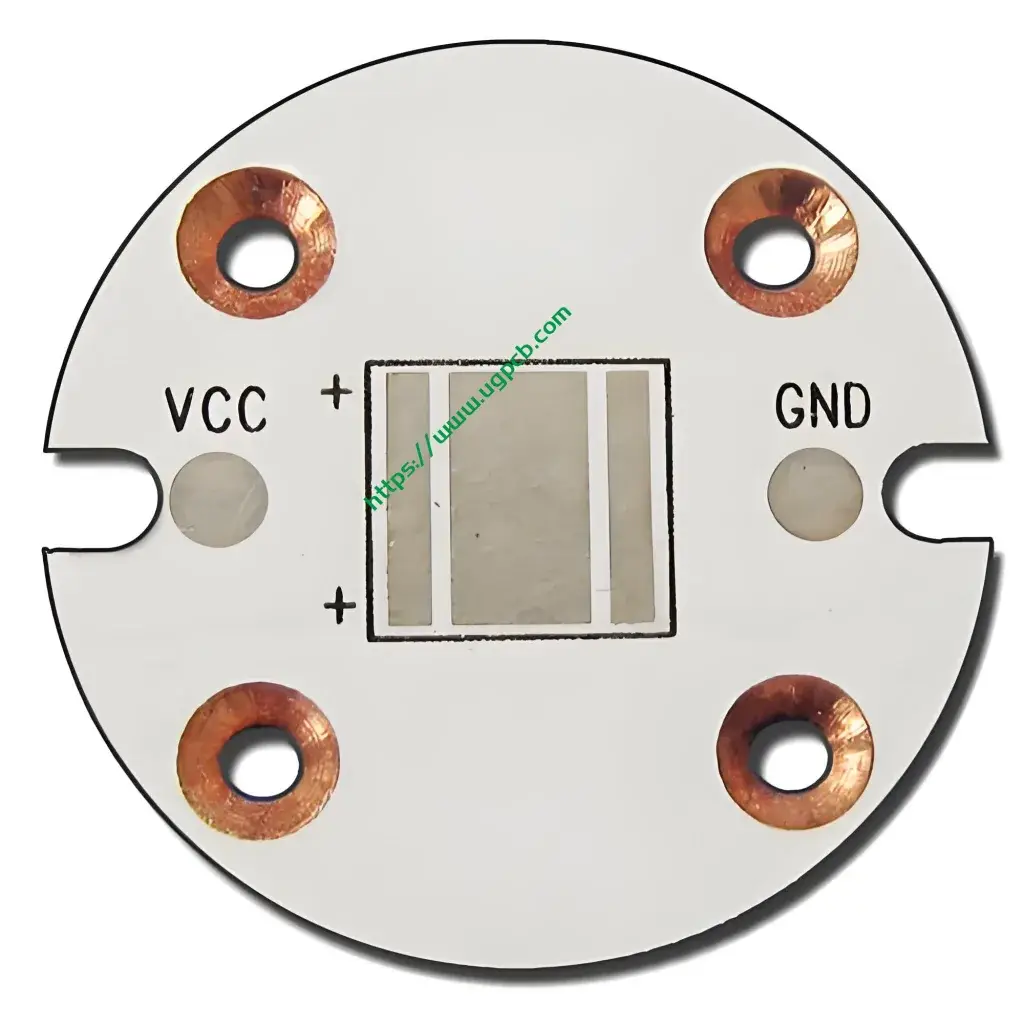

LED Counterbore Hole PCB Material

The LED counterbore hole PCB is crafted from a sturdy aluminum base, offering a robust foundation for various electronic applications. Aluminum is chosen for its excellent heat dissipation properties, lightweight nature, and resistance to corrosion, making it ideal for high-performance PCB.

Prestazione

Boasting a thermal conductivity of 1.0w/m.k, this PCB ensures efficient heat transfer, crucial for maintaining optimal performance in LED applications where heat build-up can be a significant issue. The single-layer design (1Strati) simplifies the circuitry, reducing complexity and potential points of failure.

Struttura

The PCB features a finished thickness of 1.2mm, providing a balance between durability and compactness. The copper thickness of 1OZ (ounce per square foot) ensures good electrical conductivity without adding undue weight or cost. The white or black color options allow for better aesthetic integration into diverse applications.

Special Characteristics

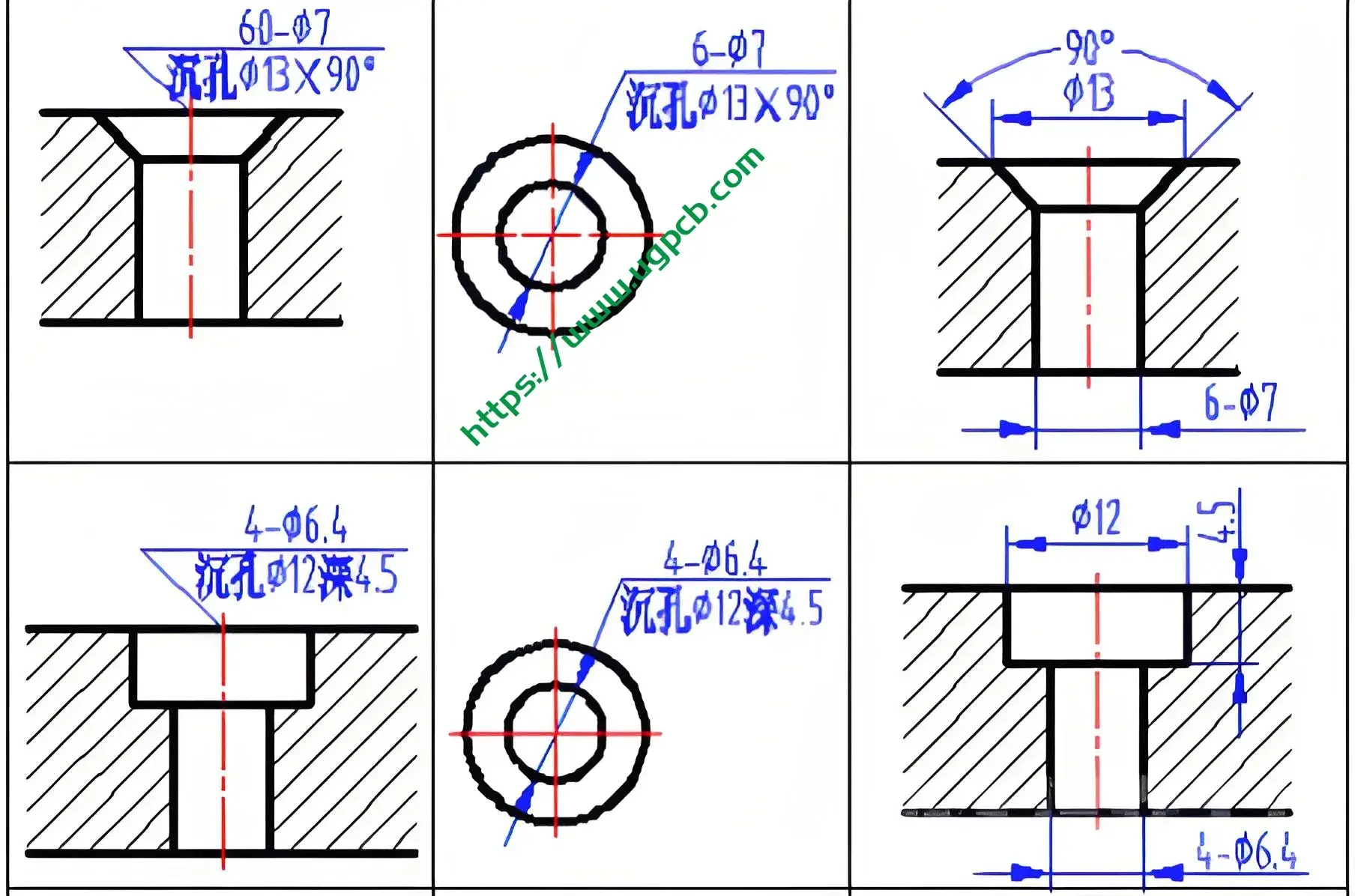

The standout feature of this PCB is the counterbore hole process. Counterboring involves enlarging the entrance of a hole to create a flat-bottomed cylindrical opening. This not only provides a cleaner, more finished look but also allows for easier and more secure mounting of components, particularly LEDs, by reducing stress on the board and enhancing mechanical stability.

Processo di produzione

- Progettazione e impaginazione: IL Progettazione di circuiti stampati is meticulously planned, including the positioning of counterbore holes and electrical traces.

- Preparazione del materiale: High-quality aluminum sheets are prepared to the specified thickness.

- Acquaforte del circuito: The copper layer is etched away in the desired pattern to form the circuitry.

- Counterboring: The holes are precisely counterbored to meet design specifications.

- Trattamento superficiale: OSP or Immersion Tin is applied to enhance solderability and protect against corrosion.

- Controllo di qualità: Each PCB undergoes rigorous testing to ensure it meets all functional and aesthetic standards.

Scenari di applicazione

This LED counterbore hole PCB is perfect for a range of LED-based applications where heat management and secure componente mounting are paramount. Questi includono:

- LED Lighting Systems: For efficient heat dissipation in LED strips, panels, and bulbs.

- Signage and Displays: Ensures reliable operation in digital signboards and advertising displays.

- Automotive Lighting: Suitable for headlights, tail lights, and interior lighting in vehicles.

- Elettronica generale: Useful in any device requiring high-brightness LEDs, such as consumer electronics and industrial machinery.

In sintesi, the LED counterbore hole PCB offers a combination of thermal efficiency, mechanical stability, and aesthetic appeal, making it an excellent choice for various LED-centric applications.

LOGO UGPCB

LOGO UGPCB