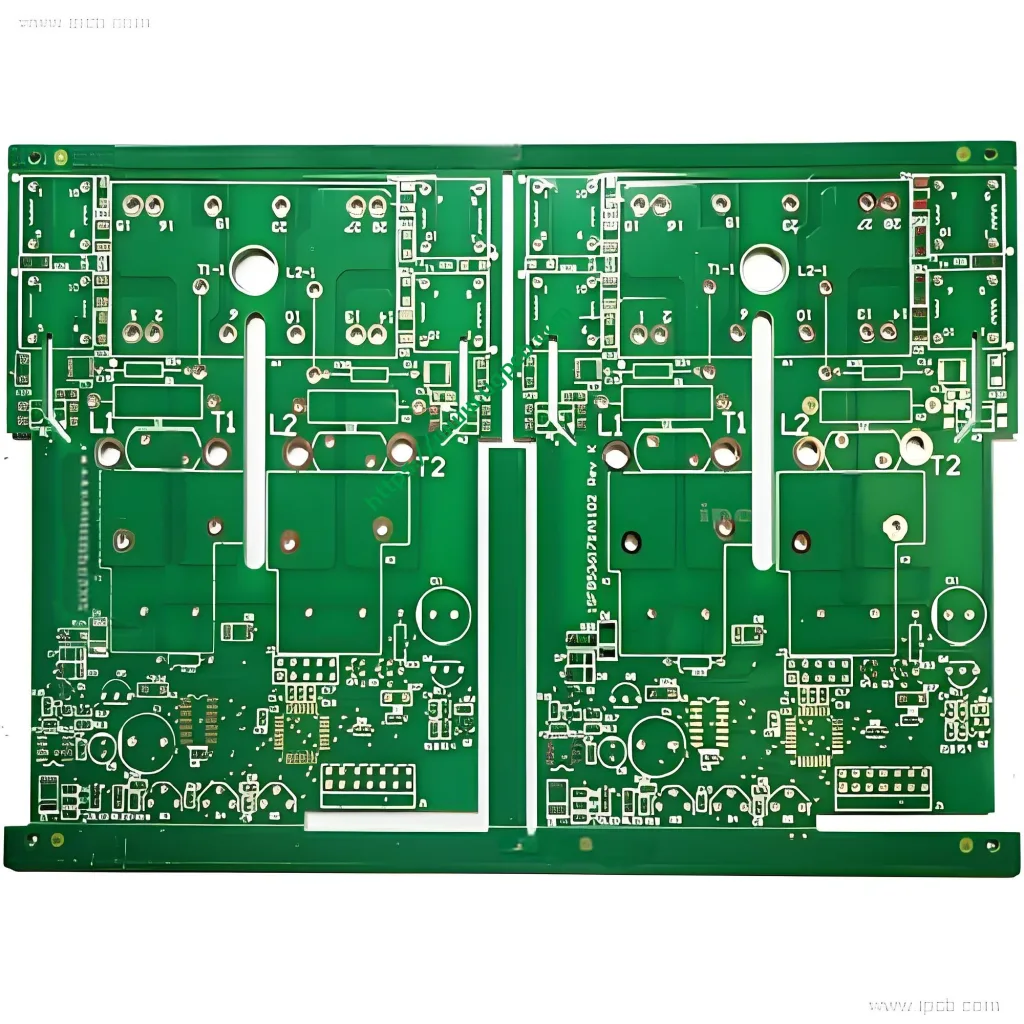

Double-Sided Power PCBs: Affidabile, High-Current Boards for Demanding Applications

In an era of high-power electronics, stable and efficient power management is critical. UN circuito stampato (PCB) optimized for power transmission and conversion is often the cornerstone of system reliability. Our double-sided power PCBs are engineered to meet the stringent challenges of high current, voltage, e gestione termica.

Panoramica del prodotto: What is a Double-Sided Power PCB?

A double-sided power PCB is a specialized printed circuit board designed to carry and distribute high current and manage substantial power across its two layers. Unlike standard signal PCBs, its core design objectives are low impedance, high current-carrying capacity, and superior thermal performance. We use FR-4 (a flame-retardant glass-reinforced epoxy laminate) as the base material, ensuring every board performs reliably in applications like power converters, azionamenti a motore, and industrial power supplies through stringent process control.

Core Specifications

-

Modello: Double-Sided Power PCB

-

Materiale di base: High-Quality FR-4

-

Conta dei strati: 2 Strati

-

Spessore della scheda: 1.6mm (Standard, excellent mechanical strength)

-

Spessore del rame (Finito): 1oz (35µm) - A key parameter for current carrying capacity. (2oz, 3oz available)

-

Finitura superficiale: HASL senza piombo (Livellamento della saldatura ad aria calda). Provides excellent solderability and cost-effectiveness.

-

Min. Traccia/spazio: 6mil (0.15mm), sufficient for most power layouts.

-

Solder Mask Color: Verde (Standard)

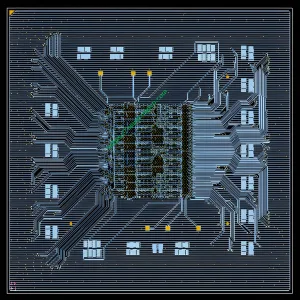

Design Essentials & Principio di lavoro

Considerazioni chiave sulla progettazione:

-

Wide Traces & Rame pesante: Power paths (per esempio., Vin, Vout, GND) use the widest possible traces with 1oz or thicker copper to minimize resistance, heat generation, and voltage drop.

-

Adequate Via Stitching: Multiple vias in arrays are used to connect the same power net on both layers, significantly reducing parasitic resistance and inductance of the vias and enhancing current capacity.

-

Gestione termica: Strategic placement of heat-generating components (per esempio., MOSFETs, induttori) alongside thermal vias E exposed copper pads to efficiently transfer heat to the opposite side or an external heatsink.

-

Safety Spacing: Electrical clearance and creepage distances for high-voltage lines are strictly set according to safety standards (per esempio., UL, IEC) to ensure operational safety.

Principio di lavoro:

The double-sided power PCB serves as a passive interconnection platform. Its function is to provide optimal electrical and physical connections for active power componenti (ICS, transformers, condensatori, induttori). Through meticulously designed high-power traces, it ensures energy is transferred from input to conversion circuitry and then to the load with minimal loss and heat generation. Effective thermal path design keeps component junction temperatures within safe limits, enabling reliable assemblaggio PCBA and long-term stable operation.

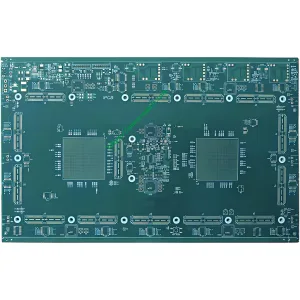

Product Categories, Materiali & Caratteristiche strutturali

Common Applications/Categories:

-

DC-DC Converter PCBs

-

AC-DC Power Supply Module PCBs

-

Motor Driver PCBs

-

Inverter/VFD PCBs

-

High-Power LED Driver PCBs

-

Sistema di gestione della batteria (BMS) PCB

Materiali utilizzati:

-

Substrato: FR-4, offering excellent insulation, resistenza meccanica, and flame retardancy (94V-0).

-

Conductive Layer: Electro-deposited copper foil (starting at 1oz, customizable to 2oz, 3oz, and beyond).

-

Maschera di saldatura: Standard green LPI (Liquid Photo-Imageable) ink for protection.

-

Finitura superficiale: Standard Lead-Free HASL. Other finishes like ENIG or OSP are available upon request.

Caratteristiche strutturali:

-

Dual-Side Layout: Components can be placed on both top and bottom layers, maximizing space for efficient power routing.

-

Reinforced Power Planes: While not having dedicated power planes, large copper pours on both layers create highly effective “pseudo” power planes.

-

Integrated Thermal Management: Features like thermal vias and large exposed copper areas facilitate heat dissipation to enclosures or heatsinks.

-

Costruzione robusta: The standard 1.6mm board thickness provides superior mechanical rigidity, suitable for heavy components like large capacitors and heatsinks.

UGPCB Standard Production Flow & Performance Advantages

Our Manufacturing Process:

DFM Review → Material Prep → Drilling → Plating (PTH) → Pattern Transfer → Pattern Plating (Copper Build-up) → Etching → Solder Mask Application → Surface Finish (Sanguinare) → Silkscreen → Electrical Testing → Final Inspection → Packaging & Spedizione

We maintain strict control over every step, particularly copper plating thickness and etch uniformity, to ensure precision and current-carrying capability of power traces.

Key Performance Advantages:

-

High Current Capacity: Optimized copper weight and trace design for handling Ampere-level currents.

-

Low Thermal Resistance: Innovative cooling features effectively reduce hot spot temperatures, extending component lifespan.

-

High Stability: Rigorous process and material control ensure stable performance in harsh environments (high temp/humidity).

-

Strong Compatibility: Proven HASL surface finish offers excellent solderability for volume PCB produzione.

-

Cost-Effective: Provides competitive pricing for both PCB quick-turn prototypes and volume production without comp

Wide Range of Applications

UGPCB’s double-sided power PCBs are the ideal choice for numerous high-power electronic devices:

-

Controllo industriale: Variable Frequency Drives (VFDs), servo drives, PLC power modules.

-

New Energy: PV inverters, Energy Storage System (ESS) power conversion systems, charging pile modules.

-

Elettronica automobilistica: On-Board Chargers (OBC), Convertitori DC-DC, motor controllers.

-

Elettronica di consumo: High-wattage adapters, gaming console PSUs, high-end audio amplifiers.

-

Telecom Equipment: Base station power supplies, network equipment power distribution boards.

Why Choose UGPCB for Your Double-Sided Power PCBs?

We understand the complexities of power Progettazione di circuiti stampati. Choosing UGPCB means gaining more than just a circuit board; you gain a reliable power solution partner. We offer comprehensive support from PCB design review E quick-turn prototyping to volume production, ensuring your product’s smooth journey from concept to market.

Contact a UGPCB sales engineer today for a customized quote and technical solution for your double-sided power PCB needs! Let our expertise empower your product with stable, reliable performance.

LOGO UGPCB

LOGO UGPCB